If you don’t have sandpaper on hand or prefer a more eco-friendly approach, there are alternative methods to sand wood effectively. One option is using a wire brush or steel wool to remove roughness and imperfections from the surface. Another technique involves using a scraper or putty knife to scrape away any raised areas. Additionally, you can use a sanding block with coarse or medium grit sandpaper to smooth the wood. These methods provide alternatives for sanding wood without traditional sandpaper.

Using Household Items for Wood Sanding

Wood sanding is an essential process in woodworking that helps achieve a smooth and polished finish on your projects. While there are various tools and equipment specifically designed for sanding, you may not always have access to them. In such situations, you can make use of some common household items to accomplish the task effectively. In this section, we will explore different household items that you can use for wood sanding.

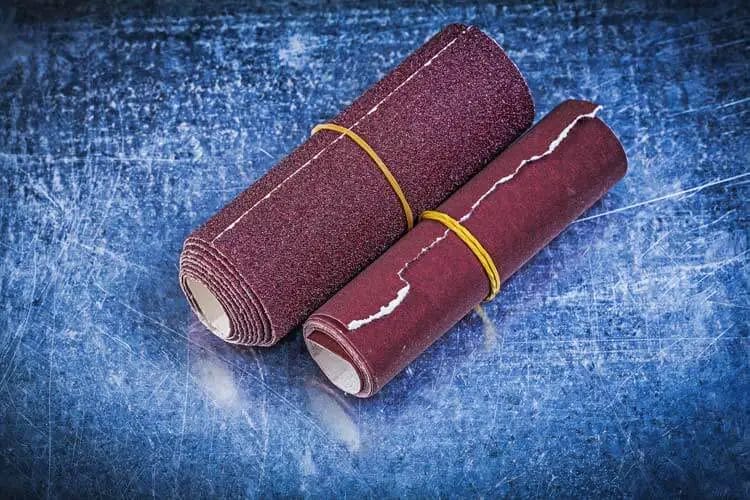

Sandpaper

Sandpaper is one of the most basic and widely used materials for wood sanding. It consists of a paper or cloth base with abrasive particles bonded to it. You can find sandpaper in different grit sizes, ranging from coarse to fine. The higher the grit number, the finer the sandpaper. For initial sanding and removing rough surfaces, a coarser grit sandpaper such as 80 or 100 can be used. As you progress towards achieving a smoother finish, you can switch to finer grits like 220 or 320.

Steel Wool

Steel wool is another household item that can be used for sanding wood. It is available in various grades, with higher numbers indicating finer strands. Steel wool can be effective in smoothing and polishing the surface of the wood. However, keep in mind that it may leave behind fine steel fibers, so it’s essential to clean the surface thoroughly after sanding with steel wool.

Emery Cloth

Emery cloth is a type of sandpaper that has abrasive particles embedded in a cloth backing. It is commonly used for metalworking but can also be useful for wood sanding. Emery cloth is durable and can withstand high pressure and friction. It is available in different grits, allowing you to choose the appropriate level of abrasiveness for your sanding needs.

Scrap Wood

Using a scrap piece of wood as a sanding block can provide stability and control during the sanding process. Simply wrap the sandpaper around the scrap wood and use it as a handle while sanding. This technique allows for an even distribution of pressure and prevents your hands from directly touching the surface, ensuring a more uniform sanding result.

Files and Rasps

Files and rasps, commonly used for shaping and smoothing metal, can also be used for sanding wood. They have sharp teeth or abrasive surfaces that can help remove material quickly. However, they may leave deep grooves or scratches on the wood, so it’s important to use them with caution and follow up with finer sandpaper for a smooth finish.

Plastic Putty Knife

A plastic putty knife can be used for light sanding tasks or when dealing with delicate wood surfaces. It is a safe alternative to metal scrapers and can help remove paint, glue, or other unwanted substances without causing damage. However, for more intensive sanding, it is recommended to use sandpaper or other more abrasive materials.

With these household items, you can effectively sand wood and achieve a smooth finish even without specialized tools. Sandpaper, steel wool, emery cloth, scrap wood, files and rasps, and plastic putty knives are versatile and readily available materials that can assist you in your woodworking projects. Remember to choose the appropriate grit and technique based on the level of sanding required. Happy sanding!

3. Eco-Friendly Wood Sanding Methods

When it comes to woodworking, sanding is an essential process that helps to achieve a smooth and polished surface. However, traditional sanding methods often involve the use of harmful chemicals and wasteful practices that are harmful to the environment. Fortunately, there are eco-friendly wood sanding methods that can be employed to minimize the ecological impact without compromising the quality of the finished product.

Sanding with Recycled Materials

One eco-friendly alternative to traditional sanding is to use recycled materials. Instead of purchasing brand new sandpaper, consider using sanding pads or sponges made from recycled materials. These products are designed to be durable and can be easily washed and reused multiple times, reducing waste and minimizing the need for new resources.

Furthermore, there are sanding pads available that are specifically designed for use with powered sanders. These pads are made from recycled synthetic fibers and offer excellent performance when it comes to smoothing wood surfaces. By utilizing these recycled materials, you can contribute to a more sustainable and environmentally friendly woodworking practice.

Using Non-Toxic Sanding Products

Another eco-friendly approach to wood sanding is to opt for non-toxic sanding products. Traditional sanding processes often involve the use of toxic chemicals such as varnish removers and sealants. These chemicals can be harmful to both human health and the environment.

Instead, consider using water-based or plant-based sanding products. These alternatives are typically non-toxic, biodegradable, and do not release harmful fumes or pollutants into the air. Not only are they better for the environment, but they also provide a safer working environment for the woodworker.

Dust Collection and Management

The dust generated during the sanding process can pose a health hazard and contribute to pollution. To minimize the impact, it is important to implement effective dust collection and management systems.

Investing in a high-quality dust collection system will help capture and contain the wood particles and dust that are generated during sanding. This not only keeps the workspace clean but also prevents the release of particles into the air, reducing the risk of respiratory issues.

Additionally, consider incorporating dust control measures such as using vacuum sanders or attaching a dust extraction system to your existing sanding equipment. These methods help to capture dust directly at the source, further minimizing the dispersion of particles into the environment.

Proper Disposal of Waste

Proper waste disposal is an important aspect of eco-friendly wood sanding. Avoid disposing of wood dust and waste in regular trash bins, as they may end up in landfills where they can contribute to pollution.

Instead, consider recycling or repurposing the wood waste. Wood dust can be used as a natural fertilizer, while larger wood scraps can be repurposed for other woodworking projects or donated to organizations that can make use of them.

Summary

Eco-friendly wood sanding methods are not only beneficial for the environment but also for the health and safety of the woodworker. By using recycled materials, non-toxic sanding products, implementing proper dust collection and management systems, and practicing responsible waste disposal, you can contribute to a more sustainable woodworking practice. Embracing these eco-friendly methods allows you to achieve a polished finish while minimizing your ecological footprint.

4. Sanding Wood without Power Tools

Sanding wood is an essential step in any woodworking project, as it helps to smooth out rough surfaces, remove imperfections, and prepare the wood for finishing. While power tools like sanders can make the task quicker and easier, there are times when you may not have access to these tools or may prefer a more traditional approach. In this section, we will explore various techniques and methods for sanding wood without power tools.

1. Sandpaper and Hand Sanding

The most basic and widely used method for sanding wood without power tools is by using sandpaper and hand sanding. Sandpaper comes in different grits, ranging from coarse to fine, allowing you to achieve different levels of smoothness on the wood surface.

To start, choose the appropriate sandpaper grit based on the level of roughness on the wood. For rough surfaces, use a coarse grit (around 60-80) and gradually move to finer grits (120-180) for smoother finishes. Wrap the sandpaper around a sanding block or use your hand for smaller areas, and sand the wood surface using even, back-and-forth strokes. Be sure to sand with the grain of the wood to avoid creating scratches or gouges.

Continue sanding with progressively finer grits until you achieve the desired smoothness. Remember to periodically check the surface with your hand to feel for any imperfections. Once you are satisfied with the smoothness, wipe away any dust or debris with a clean cloth.

2. Scraping

Scraping is another effective technique for removing rough areas and imperfections on wood surfaces. This method involves using a scraper tool, such as a putty knife or a specialized cabinet scraper, to shave off thin layers of wood.

To scrape the wood, hold the scraping tool at a slight angle and apply firm, even pressure as you push it across the surface. Work in the direction of the grain to prevent tear-out or splintering. Scraping can be particularly useful for removing paint or varnish residue, as well as for shaping curved surfaces.

While scraping requires more manual effort compared to sanding, it can yield excellent results, especially on harder wood species or intricate details where sandpaper may not be as effective.

3. Using Files and Rasps

If you need to shape or smooth irregular surfaces or contours, files and rasps can be valuable tools. Files are designed with fine, parallel rows of teeth, while rasps have larger, more aggressive teeth. Both tools are effective for removing material quickly.

To use files and rasps, hold the tool securely and apply even pressure as you move it back and forth across the wood surface. Use a coarse file or rasp to remove larger amounts of material and progressively switch to finer files to achieve a smoother finish.

4. Sanding Blocks and Contoured Sanding

When sanding flat or even surfaces, using a sanding block can provide more even pressure and control. A sanding block is typically a piece of wood or foam with a flat surface that holds the sandpaper securely in place.

For contoured or curved surfaces, you can create a custom sanding block by wrapping sandpaper around a soft material like foam or rubber. This allows the sandpaper to conform to the shape of the surface, ensuring consistent sanding.

By using sanding blocks, you can achieve smoother results and minimize the risk of uneven sanding or excessive material removal.

5. Hand Planes

If you have access to a hand plane, it can be a valuable tool for removing larger amounts of material quickly. Hand planes have a sharp blade that shaves off thin layers of wood, allowing you to level surfaces or remove rough spots.

To use a hand plane, adjust the blade depth according to the desired thickness of material to be removed. Hold the plane with both hands and apply even pressure as you push it along the wood surface. Work in the direction of the grain for the best results.

Hand planes can be particularly useful for preparing rough lumber or flattening large panels before finer sanding to achieve a smooth finish.

6. Steel Wool and Sanding Pads

In addition to sandpaper, steel wool and sanding pads can be used for intermediate or final smoothing. Steel wool comes in different grades from coarse to fine, and like sandpaper, it can be used to remove small imperfections or to prep the wood for finishes.

Sanding pads, also known as abrasive pads or finishing pads

Achieving a Smooth Finish without Sandpaper

When it comes to finishing woodwork or other surfaces, sandpaper is often the go-to tool. However, there are instances where sandpaper may not be the most suitable option. Whether you don’t have sandpaper on hand or you simply want to explore alternative methods, achieving a smooth finish without sandpaper is indeed possible. In this section, we will delve into several techniques that can help you achieve that desired polished look without the use of sandpaper.

1. Using Steel Wool

Steel wool is a versatile and effective material for achieving a smooth finish. It comes in various grades, ranging from coarse to fine, allowing you to choose the appropriate level of abrasiveness for your project. To use steel wool, simply rub it gently across the surface in circular motions. This will help remove any imperfections or roughness, leaving behind a smooth and polished finish. Remember to clean the surface thoroughly after using steel wool to remove any residual fibers.

2. Employing a Scraper

Another method to achieve a smooth finish without sandpaper is by using a scraper. A scraper is a handheld tool with a sharp edge that can effectively remove material from surfaces. There are different types of scrapers available, such as cabinet scrapers or card scrapers. To use a scraper, hold it at a slight angle and apply even pressure as you scrape across the surface. This process helps to level out any bumps or imperfections and creates a smooth finish.

3. Buffing with Polishing Compounds

Buffing is an excellent technique to achieve a smooth and glossy finish on surfaces. Instead of sandpaper, you can use polishing compounds to remove scratches, marks, or roughness. Apply a small amount of the polishing compound onto a soft cloth or buffing pad, and then gently rub it onto the surface in circular motions. This will help to smooth out the imperfections and leave behind a polished finish. Buffing is commonly used on materials such as metal, plastic, or even certain types of wood.

4. Using a Planer or Jointer

If you are working with larger surfaces or rough lumber, using a planer or jointer can help achieve a smooth finish without sandpaper. A planer is a power tool that is used to flatten and smooth the surface of wood, while a jointer is primarily used to straighten the edges. By running the material through a planer or jointer, you can effectively remove any roughness or unevenness. This will result in a smooth finish that is ready for further finishing touches.

5. Wet Sanding

While sandpaper is typically used for sanding dry surfaces, wet sanding can also be an effective method for achieving a smooth finish without traditional sandpaper. Wet sanding involves using water or a lubricant to moisten the surface while sanding. This helps to minimize the friction and heat generated during sanding, resulting in a smoother finish. Wet sanding is commonly used in automotive refinishing or when working with materials such as lacquer or varnish.

In summary, achieving a smooth finish without sandpaper is indeed possible. By utilizing alternative methods such as using steel wool, employing a scraper, buffing with polishing compounds, using a planer or jointer, or even trying wet sanding, you can achieve excellent results. Each method offers its own unique advantages and can be used in different situations depending on the material and desired finish. So, next time you find yourself without sandpaper or simply want to explore different techniques, give these methods a try and enjoy a smooth and polished outcome.

FAQs

1. How can I sand wood without sandpaper?

You can use alternative methods to sand wood without sandpaper. One option is to use a sanding sponge, which is a foam block coated with abrasive particles. Another option is to use a wire brush attachment on a power drill. Additionally, you can use a scraper or a plane to remove rough areas.

2. What can I use instead of sandpaper?

Instead of sandpaper, you can use steel wool, which is abrasive and can help smoothen the wood surface. Emery cloth, a type of abrasive fabric, can also be used for sanding wood. Another alternative is to use a sanding block or a sanding drum attachment on a power tool.

3. Can I sand wood by hand without any tools?

While it is possible to sand wood by hand without any tools, it may be more challenging and time-consuming. However, you can use various household items like old toothbrushes, scrubbing pads, or even rough-textured fabrics like burlap or denim to manually sand the wood surface.

Conclusion

In conclusion, learning how to sand wood without sandpaper can be an effective alternative for those without access to traditional sanding materials. By utilizing household items such as steel wool, sanding sponges, or even a plane, you can achieve smooth and polished surfaces on your wooden projects. Additionally, exploring alternative techniques such as hand scraping or using a power tool with a wire brush attachment can also yield satisfactory results. Remember to always follow proper safety precautions and test any new methods on a small, inconspicuous area before proceeding with larger surfaces. With a little creativity and resourcefulness, you can achieve professional-quality woodworking without relying solely on sandpaper.