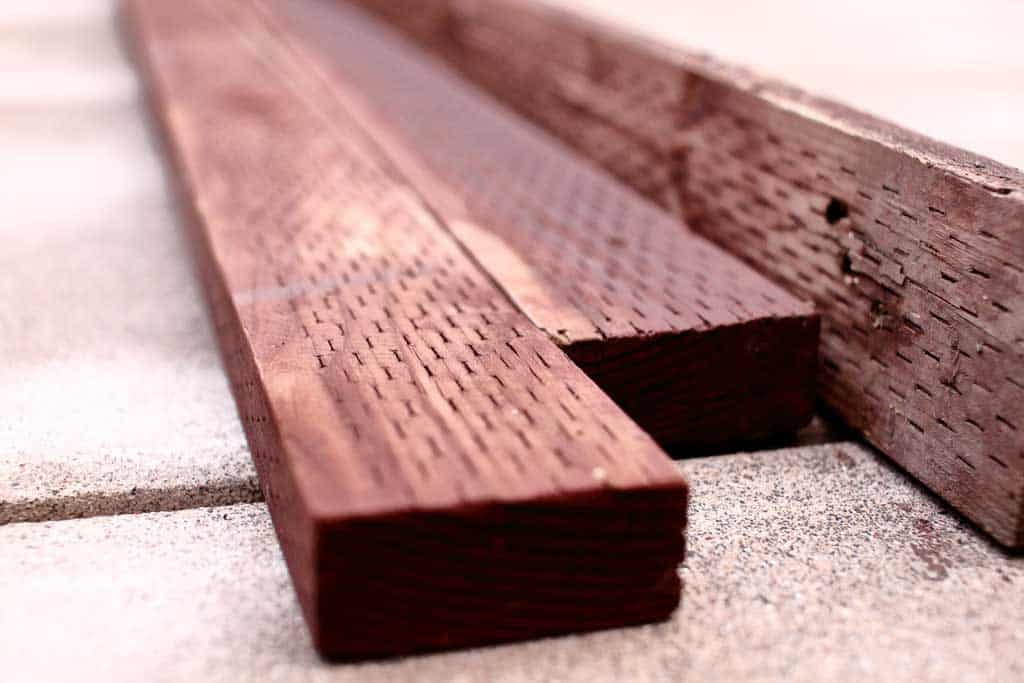

Pressure treated wood is a popular choice for various projects due to its affordability. The lower cost of pressure treated wood can be attributed to the manufacturing process it undergoes. By subjecting the wood to high pressure and infusing it with preservatives, it becomes more resistant to rot, insects, and decay, making it a durable and long-lasting option. This treatment process allows for the use of lower-quality wood, which ultimately brings down the overall cost. As a result, pressure treated wood offers a cost-effective solution for those seeking a sturdy and budget-friendly material for their construction, landscaping, or outdoor projects.

Cost Savings of Using Pressure Treated Wood

Pressure treated wood is a popular choice for a wide range of construction projects. It is specially treated with preservatives to protect it from rot, decay, and insect infestation, making it more durable and long-lasting than untreated wood. While pressure treated wood may have a slightly higher upfront cost compared to untreated wood, it offers significant cost savings in the long run. In this section, we will explore the various ways in which using pressure treated wood can lead to cost savings.

1. Enhanced Durability

One of the primary benefits of pressure treated wood is its enhanced durability. The preservatives used in the treatment process improve the wood’s resistance to moisture, fungal decay, and insect damage. As a result, structures built with pressure treated wood tend to last longer and require fewer repairs or replacements over time. This durability translates into cost savings as you won’t have to spend money on frequent maintenance or replacement of deteriorating wood.

2. Reduced Maintenance Costs

Compared to untreated wood, pressure treated wood requires minimal maintenance. It is naturally resistant to rot and decay, reducing the need for costly treatments, sealants, or paints to protect it from the elements. With pressure treated wood, you can save on regular maintenance expenses, such as sanding, staining, and sealing, which can add up over time.

3. Protection Against Insects and Pests

Wood-boring insects and termites can wreak havoc on untreated wood, causing structural damage that may require costly repairs. Pressure treated wood acts as a deterrent to these pests, providing long-term protection. By using pressure treated wood, you can avoid the expenses associated with pest control treatments or the need to replace infested wood.

4. Extended Lifespan

Pressure treated wood has a longer lifespan compared to untreated wood. Over time, untreated wood can deteriorate, warp, or succumb to rot and decay. This can lead to safety hazards and additional costs for replacements. Pressure treated wood, on the other hand, can withstand harsh weather conditions and remain structurally sound for many years. Its extended lifespan translates into long-term cost savings.

5. Insurance Premium Benefits

Using pressure treated wood in certain construction projects, such as decks or outdoor structures, may also have an impact on your insurance premiums. Insurance companies often view pressure treated wood favorably due to its resistance to rot and insect damage. As a result, you may be eligible for lower insurance premiums, which can lead to savings over time.

Overall, the cost savings associated with using pressure treated wood are significant. From enhanced durability and reduced maintenance costs to protection against insects and a longer lifespan, pressure treated wood proves to be a smart investment. While the initial cost may be slightly higher, the long-term benefits far outweigh the upfront expenses. If you want to save money on maintenance, repairs, and replacements in the future, pressure treated wood is the way to go.

Factors that Make Pressure Treated Wood More Affordable

Pressure treated wood is a popular choice for outdoor projects such as decks, fences, and landscaping structures due to its durability and resistance to rot and insects. One of the reasons why pressure treated wood is widely used is its affordability compared to other wood options. In this section, we will explore the factors that contribute to the cost-effectiveness of pressure treated wood.

1. Easy Availability

Pressure treated wood is readily available in most hardware stores and lumberyards. Its widespread availability makes it more affordable because it reduces transportation costs. It also eliminates the need for special orders or lengthy delivery times, making it a convenient and cost-effective choice for consumers.

2. Low Production Costs

The production process of pressure treated wood involves treating the lumber with preservatives under high pressure. This method is relatively cost-effective, as it allows for mass production at a lower cost per unit. The preservatives used in the treatment process are also affordable, contributing to the overall lower production costs.

3. Long Lifespan

Pressure treated wood has a longer lifespan compared to untreated wood. The treatment process involves impregnating the wood with chemicals that provide protection against rot, decay, and insect infestation. This increased durability means that pressure treated wood requires less frequent replacement, resulting in long-term cost savings for homeowners.

4. Reduced Maintenance Expenses

Due to its resistance to rot and insects, pressure treated wood requires minimal maintenance compared to untreated wood. Regular sealing or staining is not necessary, which translates to cost savings in terms of time, labor, and money. The reduced need for maintenance makes pressure treated wood a more affordable option for budget-conscious individuals.

5. Versatility

Pressure treated wood can be used for a wide range of projects, from outdoor furniture to structural elements. Its versatility makes it a popular choice among DIY enthusiasts and contractors alike. By opting for pressure treated wood, individuals can save on the cost of purchasing different materials for various projects, resulting in overall affordability.

6. Resilience to Harsh Weather Conditions

Pressure treated wood is designed to withstand exposure to harsh weather conditions, including moisture, UV rays, and temperature fluctuations. Its resilience reduces the risk of damage and premature deterioration, which can lead to costly repairs or replacements. The ability of pressure treated wood to withstand the elements contributes to its long-term affordability.

7. Sustainability

Pressure treated wood is often sourced from sustainably managed forests, which helps to minimize environmental impact. Many suppliers follow responsible forestry practices and obtain certification to ensure the wood’s sustainability. Choosing sustainable materials aligns with the growing demand for eco-friendly options and can be an affordable choice for those who prioritize environmental ethics.

8. Easy Installation

Pressure treated wood is relatively easy to work with and install, requiring fewer specialized tools or skills. The simplicity of installation can save homeowners money by eliminating the need for professional contractors. This do-it-yourself approach reduces labor costs and further enhances the affordability of pressure treated wood.

In summary, pressure treated wood offers a cost-effective solution for outdoor construction projects. Its affordability is influenced by factors such as easy availability, low production costs, long lifespan, reduced maintenance expenses, versatility, resilience to harsh weather conditions, sustainability, and easy installation. By considering these factors, individuals can make informed decisions and choose pressure treated wood as a budget-friendly option while enjoying its many benefits.

Comparison of Prices: Pressure Treated Wood vs. Other Materials

When it comes to choosing the right material for your outdoor projects, cost is often a significant factor to consider. In this section, we will compare the prices of pressure treated wood with other commonly used materials, helping you make an informed decision based on your budget and needs.

Pressure Treated Wood

Pressure treated wood is a popular choice for outdoor applications such as decking, fences, and pergolas due to its durability and resistance to rot and insects. The wood is treated with chemicals that make it weather-resistant, extending its lifespan.

In terms of cost, pressure treated wood tends to be more budget-friendly compared to other materials, making it an attractive option for those looking to complete their projects within a limited budget. The affordability of pressure treated wood is one of its major advantages, making it a popular choice for both DIY enthusiasts and professionals alike.

Composite Decking

Composite decking is an alternative to traditional wood decking that is made from a combination of wood fibers and recycled plastics. It offers the look and feel of wood without the required maintenance, as it is resistant to rot, fading, and staining.

When comparing the prices, composite decking tends to be more expensive than pressure treated wood. However, the additional cost can be justified by the longevity and low maintenance requirements of composite decking, which may save you money in the long run.

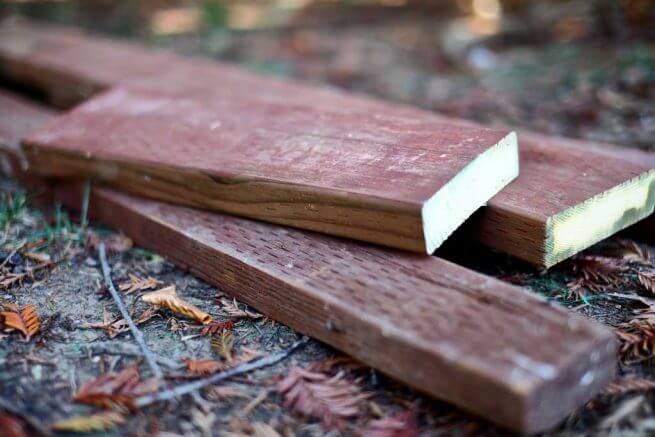

Cedar

Cedar is a popular choice for outdoor projects due to its natural beauty and resistance to decay. It is known for its rich color and pleasant aroma. Cedar is a durable and lightweight wood that is easy to work with, making it an ideal material for various applications.

In terms of cost, cedar is generally more expensive than pressure treated wood. However, it is important to consider the long-term benefits of cedar, such as its resistance to rot and insects, which can save you money on maintenance and replacement costs in the future.

Redwood

Redwood is another popular choice for outdoor projects, known for its natural beauty and durability. It is a naturally resistant wood that is able to withstand harsh weather conditions and resist rot and insects.

In terms of price, redwood is usually more expensive than pressure treated wood. However, similar to cedar, the long-term benefits of redwood, such as its longevity and low maintenance requirements, can outweigh the initial higher cost.

Summary

When comparing the prices between pressure treated wood and other materials, it is essential to consider your budget, the specific requirements of your project, and the long-term benefits of each material. While pressure treated wood tends to offer a more affordable option upfront, composite decking, cedar, and redwood can provide additional advantages in terms of longevity and low maintenance. Ultimately, the choice between materials will depend on your personal preferences, budget constraints, and the desired lifespan of your outdoor project.

Tips for finding the best deals on pressure treated wood

Pressure treated wood is a popular choice for outdoor projects due to its durability and resistance to rot and insect damage. However, buying pressure treated wood can be costly, especially if you’re working on a larger project. Fortunately, there are ways to find the best deals on pressure treated wood without compromising on quality. Here are some tips to help you save money:

1. Comparison shop

Before making a purchase, take the time to compare prices from different suppliers. Visit local home improvement stores, lumberyards, and online retailers to get an idea of the average cost. Keep in mind that prices can vary significantly, so it’s worth checking multiple sources.

2. Look for sales and promotions

Keep an eye out for sales and promotions on pressure treated wood. Many stores offer discounts during specific seasons, such as spring and summer when outdoor projects are more common. Sign up for newsletters or follow retailers on social media to stay updated on any special deals.

3. Buy in bulk

If you have a large project or plan to use pressure treated wood frequently, consider buying in bulk. Purchasing larger quantities can often lead to discounted prices. Look for wholesalers or suppliers that offer bulk discounts, as this can significantly reduce the cost per board.

4. Consider alternative sources

Don’t limit yourself to traditional retailers when searching for pressure treated wood. Explore alternative sources such as salvage yards, construction sites, or classified ads. These places may have leftover or reclaimed pressure treated wood available at a lower cost.

5. Check for quality

While it’s essential to find the best deals, don’t forget to consider the quality of the pressure treated wood. Inspect each board for signs of damage, such as warping, cracking, or excessive knots. Choose boards that are straight and free from any visible flaws, as these will be more durable in the long run.

6. Consider DIY treatment

If you’re comfortable with the process, you may consider treating the wood yourself. Purchasing untreated wood and applying a pressure treatment solution can be a cost-effective option. However, keep in mind that this requires additional time and effort, so weigh the pros and cons before deciding.

7. Utilize online marketplaces

Online marketplaces like Craigslist or Facebook Marketplace can be a great resource for finding pressure treated wood at a lower cost. Many individuals sell leftover or unused materials at a discounted price. Just be sure to arrange a safe meeting place and inspect the wood before purchasing.

8. Ask for contractor discounts

If you’re working with a contractor or plan to hire one for your project, ask if they can provide any discounts on pressure treated wood. Contractors often have relationships with suppliers and may be able to get better pricing.

9. Consider alternative wood options

While pressure treated wood is popular, it’s not the only option for outdoor projects. Explore alternatives such as cedar or redwood, which are naturally rot-resistant. Although these wood types may be more expensive upfront, they can offer long-term savings by eliminating the need for pressure treatment.

In summary, finding the best deals on pressure treated wood requires some research and consideration. By comparing prices, looking for sales, buying in bulk, exploring alternative sources, checking for quality, considering DIY treatment, utilizing online marketplaces, asking for contractor discounts, and considering alternative wood options, you can save money on your outdoor projects without compromising on the quality of the materials used.

FAQs

Why is pressure treated wood cheaper?

Pressure treated wood is cheaper because it undergoes a process where chemicals are forced into the wood to make it more resistant to decay and insects. This process is relatively inexpensive, allowing manufacturers to produce pressure treated wood at a lower cost compared to other types of wood.

Conclusion

In conclusion, pressure treated wood is a cost-effective choice for various construction projects due to its affordability compared to other wood options. The treatment process involves infusing chemicals into the wood, which enhances its durability and resistance to decay, pests, and rot. This increases the lifespan of pressure treated wood, making it a long-lasting and budget-friendly solution. Additionally, the widespread availability of pressure treated wood in the market contributes to its lower price point.

Furthermore, pressure treated wood offers versatility, making it suitable for both indoor and outdoor applications. Its ability to withstand harsh weather conditions and moisture exposure makes it an ideal choice for outdoor structures like decks, fences, and garden furniture. The combination of its affordable price, durability, and versatility makes pressure treated wood a popular option for many homeowners and builders seeking cost-effective and reliable materials for their projects.