Wood is not typically visible on X-ray images as it is a non-metallic material that has low X-ray attenuation properties. X-rays are mainly absorbed by denser materials like bones and metals, making it difficult to detect wooden objects using this imaging technique alone.

However, if the wooden object has any metal components or is impregnated with contrasting materials, it may be visible on X-ray images. In such cases, the metal components or contrasting materials would appear on the X-ray while the wooden portion may appear as a less dense area.

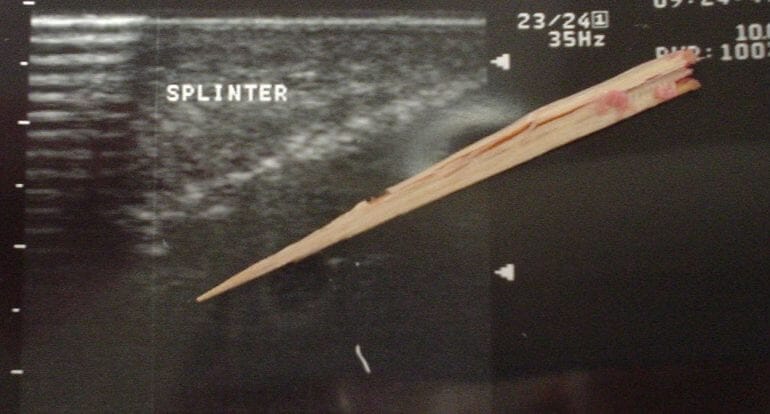

Alternative imaging techniques such as ultrasound or magnetic resonance imaging (MRI) may be more suitable for visualizing wooden objects without the need for metal components or contrasting materials.

The Use of X-rays in Identifying Wood Materials

Wood is a versatile and widely used material in construction, furniture making, and various other industries. However, identifying and classifying different types of wood can be challenging, especially when the samples are small, damaged, or weathered. This is where the use of X-rays comes in.

By utilizing X-ray technology, experts can gain valuable insights into the internal structure of wood, helping them identify the species, age, and condition of the material. X-rays have proven to be a powerful tool in the field of wood materials science and have revolutionized the way we study and analyze wood samples.

1. X-ray Imaging Techniques

X-ray techniques used for wood identification primarily include X-ray radiography and X-ray computed tomography (CT). X-ray radiography involves passing X-rays through a wood sample and capturing the resulting image on a sensor or film. This technique allows for the visualization of the wood’s internal features, such as growth rings, knots, and defects.

X-ray CT, on the other hand, takes the imaging process a step further by providing detailed three-dimensional representations of the wood’s internal structure. It allows researchers to analyze the density variations, anatomical features, and even detect the presence of insects or decay within the wood.

2. Benefits of X-ray Analysis

The use of X-rays in identifying wood materials offers several significant advantages:

- Non-destructive Analysis: X-ray analysis is non-destructive, meaning that it does not damage or alter the wood sample in any way. This is particularly useful when dealing with valuable or irreplaceable specimens.

- High Resolution: X-ray imaging techniques provide high-resolution images, allowing for precise analysis of the wood’s internal structure, including microscopic features that may not be visible to the naked eye.

- Rapid and Efficient: X-ray analysis is a relatively quick process, providing results in a matter of minutes. This efficiency is beneficial for large-scale projects or situations where prompt identification is required.

- Objective and Reliable: X-ray images provide objective data that can be analyzed and compared by multiple experts, ensuring consistent and reliable results in wood identification.

3. Applications of X-ray Analysis in Wood Science

The use of X-rays in wood science has various practical applications:

- Species Identification: X-ray analysis enables the accurate identification of wood species based on their distinctive anatomical features, helping in the prevention of illegal logging and ensuring the use of sustainable sourced wood.

- Age Estimation: By examining the growth rings and density patterns in wood samples, X-ray imaging can help estimate the age of the tree from which the wood originated.

- Detection of Defects: X-rays can detect internal defects in wood, such as cracks, decay, or insect infestations, which may not be visible externally. This information is crucial for assessing the quality and integrity of the wood material.

- Preservation and Restoration: X-ray analysis plays a crucial role in the preservation and restoration of historical or antique wooden artifacts, helping conservators understand the internal structure and condition of the objects without causing any harm.

4. Limitations and Considerations

While X-ray analysis is a powerful tool for wood identification, it does have its limitations. Some factors to consider include:

- Sample Size: The size of the wood sample can affect the quality and clarity of the X-ray image. Larger samples tend to provide better results than smaller ones.

- Sample Preparation: Proper preparation of the wood samples is essential for accurate analysis. Cleaning, drying, and positioning the sample correctly can significantly impact the quality of the X-ray image.

- Interpretation by Experts: X-ray images require interpretation by skilled experts who can identify and analyze the various features present in the wood. Experience and expertise are crucial for accurate identification.

Summary

The use of X-rays in identifying wood materials has revolutionized the field of wood science. Through non-destructive analysis, high-resolution imaging, and objective results, X-ray techniques provide valuable insights into the internal structure of wood, aiding in species identification, age estimation, defect detection, and preservation efforts. While limitations exist, X-ray analysis remains an

Advancements in X-ray Technology for Wood Detection

Wood detection plays a crucial role in various industries, such as construction, furniture manufacturing, and forestry. Traditional methods of detecting wood defects and evaluating its quality often involve visual inspection, which is time-consuming and subjective. However, with the advancements in X-ray technology, the detection of wood defects has become more efficient and accurate.

1. Non-destructive Testing

One of the key advantages of using X-ray technology for wood detection is its non-destructive nature. X-ray scanners can evaluate the internal structure of wood without causing any damage to the material. This allows for thorough inspection and analysis without compromising the integrity of the wood.

By using X-ray scanners, inspectors can identify various defects, such as knots, cracks, decay, and internal voids, which may not be visible to the naked eye. This enables manufacturers to make informed decisions about the usability and quality of the wood, minimizing the risk of using defective materials in their products.

2. High-resolution Imaging

X-ray technology has greatly improved in terms of image quality and resolution. Modern X-ray scanners can capture detailed images of the internal structure of wood, providing valuable information about its density, moisture content, and potential defects.

These high-resolution images allow inspectors to detect even the smallest cracks and voids, ensuring that only high-quality wood is used in construction or manufacturing processes. By identifying defects early on, manufacturers can take appropriate measures to prevent further damage and maintain product quality.

3. Automated Analysis

Another significant advancement in X-ray technology for wood detection is the integration of automated analysis software. This software utilizes artificial intelligence algorithms to interpret X-ray images and identify potential defects or anomalies.

By automating the analysis process, inspectors can save time and improve accuracy in wood detection. The software can quickly analyze large volumes of X-ray images, flagging areas of concern and providing detailed reports on the condition of the wood. This allows manufacturers to streamline their quality control processes and ensure consistent product standards.

4. Portable X-ray Systems

Traditionally, X-ray technology for wood detection was limited to large, stationary machines. However, advancements in portable X-ray systems have made wood inspection more accessible and convenient.

Portable X-ray systems are compact and lightweight, allowing inspectors to carry out on-site wood detection without the need for transporting wood samples to a central facility. This significantly reduces logistics costs and enables real-time inspection and decision-making.

5. Integration with Industry 4.0

X-ray technology for wood detection has also embraced the concept of Industry 4.0, integrating with other technologies to optimize processes and increase efficiency. For example, X-ray scanners can be connected to a centralized database or cloud system, allowing for seamless data storage and analysis.

Additionally, X-ray systems can be integrated into automated production lines, enabling real-time quality control and minimizing the risk of defective products reaching the market. This level of integration enhances overall productivity and ensures consistent quality standards throughout the wood manufacturing industry.

In Summary

Advancements in X-ray technology have revolutionized wood detection by providing non-destructive testing, high-resolution imaging, automated analysis, portable systems, and integration with other technologies. These advancements have significantly improved the efficiency, accuracy, and reliability of wood inspection, enabling manufacturers to produce high-quality products while minimizing waste and costs.

Challenges in Detecting Wood using X-ray Imaging

Wood is a widely used material in various industries, including construction, furniture, and packaging. It is important to ensure the quality and integrity of wood products to meet industry standards and customer expectations. X-ray imaging has emerged as an efficient non-destructive testing method for detecting internal defects in wood. However, there are several challenges involved in effectively detecting wood using X-ray imaging.

1. Density Variations

Wood is a heterogeneous material with variations in density throughout its structure. These density variations can lead to variations in X-ray attenuation, making it difficult to accurately detect defects such as cracks or voids. The X-ray image may appear blurry or unclear due to the differences in density between the wood and the defects.

2. X-ray Absorption by Moisture Content

The moisture content of wood plays a significant role in its X-ray absorption properties. Moisture can cause higher X-ray attenuation, leading to decreased image contrast and visibility of defects. Additionally, the moisture content can vary across different parts of the wood, making it challenging to obtain consistent and reliable X-ray images.

3. Thickness Variations

Wood can have varying thicknesses, especially in the case of engineered wood products. These thickness variations can affect the X-ray penetration and absorption, resulting in inconsistencies in the detected defects. It is essential to account for thickness variations and adjust the X-ray parameters accordingly to ensure accurate defect detection.

4. High Aspect Ratio Defects

Certain defects in wood, such as long cracks or fractures, can have a high aspect ratio, which means they are long and narrow compared to their width. Detecting these high aspect ratio defects using X-ray imaging can be challenging as they may appear as thin lines in the image and can be easily missed or misinterpreted.

5. Image Processing Complexity

X-ray images of wood often require complex image processing techniques to enhance the visibility of defects and differentiate them from natural wood features. Developing efficient algorithms for image processing and defect recognition is a constant challenge in the field of wood inspection using X-ray imaging.

6. Cost and Accessibility

X-ray imaging systems can be expensive to acquire and maintain, making them less accessible for small-scale or budget-limited operations. The cost factor can limit the deployment of X-ray imaging technology for wood detection, especially in certain industries or regions with limited resources.

In summary, while X-ray imaging is a promising technique for detecting wood defects, there are challenges related to density variations, moisture content, thickness variations, high aspect ratio defects, image processing complexity, and cost. Overcoming these challenges requires ongoing research and development to refine the imaging techniques, improve algorithms, and make the technology more accessible to different sectors of the wood industry.

Applications of X-ray Imaging in Woodworking and Construction

X-ray imaging technology has revolutionized various industries, including woodworking and construction. With its ability to penetrate solid objects and produce detailed images, X-ray imaging has become an invaluable tool in these fields. In this section, we will explore the different applications of X-ray imaging in woodworking and construction.

1. Quality Control and Inspection

One of the primary applications of X-ray imaging in woodworking and construction is quality control and inspection. X-ray imaging can detect internal defects and structural issues that are not visible to the naked eye. In the woodworking industry, X-ray imaging is used to inspect wooden boards and identify any hidden defects such as knots, cracks, or insect infestations. This helps ensure that only high-quality wood is used in the production process.

In the construction industry, X-ray imaging is used to inspect concrete structures and detect any hidden flaws or voids. This is particularly important in critical infrastructure projects such as bridges and tunnels, where structural integrity is crucial. X-ray images can reveal the presence of voids, cracks, or corroded steel reinforcement, allowing engineers to take necessary actions to prevent potential failures.

2. Non-Destructive Testing

X-ray imaging is also widely used for non-destructive testing in woodworking and construction. Non-destructive testing refers to the evaluation of materials or structures without causing any damage. X-ray imaging allows inspectors to assess the internal condition of materials or structures without the need for destructive sampling.

In woodworking, X-ray imaging is used to examine the internal structure of wooden beams, furniture, and other wooden components. This helps identify any defects, such as internal decay or hidden nails, which may compromise the structural integrity. By using X-ray imaging, woodworkers can make informed decisions about the usability and durability of wood materials.

In construction, X-ray imaging is commonly used to inspect welds in steel structures. Welds are critical components in construction, and any defects or flaws can weaken the overall structure. X-ray imaging allows inspectors to assess the quality of the welds and identify any imperfections that may require repair or reinforcement.

3. Damage Assessment and Forensic Analysis

Another important application of X-ray imaging in woodworking and construction is damage assessment and forensic analysis. When accidents or failures occur, X-ray imaging can be used to investigate the extent of the damage and determine the cause.

In woodworking, X-ray imaging is utilized to assess the internal damage of wooden structures after incidents such as fire, floods, or impact. It helps identify the areas affected by the damage and determine the appropriate remedial actions. X-ray images can reveal hidden structural weaknesses or compromised joints that may pose a safety risk.

In construction, X-ray imaging is used for forensic analysis of building failures or collapses. By examining the X-ray images of the failed structures, investigators can determine the root cause of the failure, such as faulty construction or material defects. This information is crucial for improving building codes and practices to prevent similar failures in the future.

4. Material Identification and Analysis

X-ray imaging is also utilized for material identification and analysis in woodworking and construction. By analyzing the X-ray images, experts can determine the composition and characteristics of various materials.

In woodworking, X-ray imaging can help identify different types of wood species based on their unique density and internal structure. This is particularly useful in the timber industry, where the accurate identification of wood species is important for quality control and regulatory compliance.

In construction, X-ray imaging is used to analyze the composition of materials such as concrete or composite materials. It can detect the presence of reinforcing materials, assess the uniformity of concrete mixes, and identify any material defects or inconsistencies.

5. Imaging and Visualization

Lastly, X-ray imaging plays a vital role in imaging and visualization in woodworking and construction. It provides detailed and accurate images of internal structures, allowing professionals to visualize the unseen.

In woodworking, X-ray imaging is used to create detailed images of wooden artifacts, sculptures, or antique furniture. These images can help conservators analyze the construction techniques, identify hidden features, or detect any alterations or repairs made to the objects over time.

In construction, X-ray imaging is employed to create 3D images or models of building components. This enables architects and engineers to visualize the internal layout of structures, identify potential clashes or interferences, and optimize the design or renovation process.

In summary, X-ray imaging has a wide range of applications in woodworking and construction. From quality control and inspection to non-destructive testing, damage assessment, material analysis, and visualization, X-ray imaging provides

FAQs

Does wood show up on X-ray?

No, wood typically does not show up on X-ray images. X-rays are primarily used to visualize dense materials like bones and metal. However, certain types of treated or impregnated wood may have enough density to be visible on X-ray scans.

Conclusion:

In conclusion, while wood is not typically visible on standard X-ray imaging, it can still be detected using other imaging techniques such as computed tomography (CT) scanning. CT scans provide more detailed images and can reveal the presence of wood in certain situations, such as detecting wooden foreign bodies lodged in the body. This capability is particularly useful in medical settings where wood fragments may have inadvertently entered the body, especially in cases of accidents or injuries involving wooden objects. Therefore, when necessary, healthcare professionals can rely on advanced imaging methods like CT scans to accurately diagnose and treat patients with suspected wood-related injuries.