If you’re wondering how long it takes to kiln dry wood, you’re in the right place. Kiln drying is a controlled process that accelerates the natural drying of wood, reducing its moisture content and making it suitable for various applications. The time required for kiln drying wood depends on several factors, including the species, thickness, and initial moisture content of the wood. In general, it can take anywhere from a few days to several weeks to complete the kiln drying process.

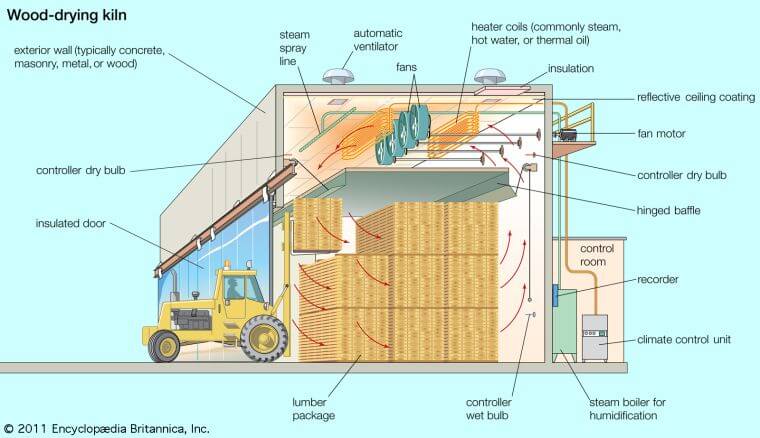

During kiln drying, the wood is placed in a specialized chamber where temperature, humidity, and airflow are carefully controlled. This controlled environment allows the wood to lose moisture gradually without compromising its structural integrity. By removing excess moisture, kiln drying significantly reduces the risk of warping, cracking, and other defects in the finished wood products.

Various factors can affect the duration of kiln drying. First and foremost, the species of wood plays a crucial role. Some species have higher moisture content and require longer drying times compared to others. The thickness of the wood is another important factor to consider. Thicker pieces of wood will take longer to dry than thinner ones.

The initial moisture content of the wood is also a significant factor. Green or freshly cut wood has a much higher moisture content compared to air-dried or partially dried wood. Therefore, green wood will generally take longer to kiln dry compared to partially dried wood.

While there

Benefits of Kiln Dried Wood: Why It’s Worth the Wait

When it comes to choosing wood for your projects or firewood needs, there are various options available in the market. One popular choice among professionals and enthusiasts alike is kiln dried wood. Although it may require a longer waiting period compared to other types of wood, the benefits it offers make it well worth the wait.

1. Enhanced Stability

Kiln drying involves the controlled application of heat and airflow to remove moisture from the wood. This process helps to reduce the moisture content to a specific level, resulting in a more stable and reliable material. Kiln dried wood is less likely to warp, twist, or crack compared to air-dried or green wood, making it ideal for furniture making, construction, and other woodworking projects.

2. Improved Strength

The removal of excess moisture during the kiln drying process also contributes to the increased strength of the wood. With lower moisture content, kiln dried wood becomes denser, which enhances its structural integrity and overall strength. This makes it a preferred choice for applications that require robust and durable wood, such as flooring, decking, and outdoor furniture.

3. Reduced Weight

Another advantage of kiln dried wood is its lower weight compared to freshly cut or air-dried wood. The removal of moisture through kiln drying reduces the wood’s density, resulting in a lighter material. This weight reduction can be beneficial in projects where weight is a concern, such as building structures or transportation.

4. Decreased Insect Infestation and Decay

Moist wood is more susceptible to insect infestation and decay. Kiln drying effectively eliminates insect eggs, larvae, and spores that may be present in the wood, reducing the risk of infestation and decay. This makes kiln dried wood a more reliable and long-lasting choice for outdoor applications, such as decking, fencing, and siding.

5. Improved Burning Efficiency for Firewood

If you’re using wood for heating or fireplace purposes, kiln dried wood offers several advantages over other types of firewood. The lower moisture content of kiln dried wood allows for a cleaner and more efficient burn, producing more heat and less smoke. It also reduces the risk of creosote buildup in chimneys, minimizing the need for frequent maintenance and ensuring better air quality.

6. Eco-Friendly Choice

Kiln drying is an environmentally friendly process that minimizes waste and reduces the demand for freshly cut wood. By utilizing the moisture already present in the wood and carefully controlling the drying process, kiln dried wood helps to conserve natural resources and reduce carbon emissions. Choosing kiln dried wood supports sustainable practices and contributes to a greener future.

In summary, the benefits of kiln dried wood outweigh the longer waiting period it may require. With enhanced stability, improved strength, reduced weight, decreased risk of insect infestation and decay, improved burning efficiency for firewood, and its eco-friendly nature, kiln dried wood is a valuable choice for a wide range of applications. Whether you’re working on a woodworking project or need firewood for your home, kiln dried wood is worth the wait.

Factors Affecting the Drying Time of Wood in a Kiln

Wood drying is a crucial process in the lumber industry, as it helps to reduce moisture content and improve the quality and stability of the wood. Kiln drying is one of the most common methods used to dry wood, as it offers controlled conditions that allow for efficient and uniform drying. However, the drying time of wood in a kiln can vary based on several factors that need to be taken into consideration. In this section, we will explore these factors and their impact on the drying time.

1. Wood Species

The type of wood species plays a significant role in determining the drying time in a kiln. Different wood species have varying densities and moisture content, which affect the amount of moisture that needs to be removed. Generally, hardwoods such as oak and maple take longer to dry compared to softwoods like pine and fir due to their higher density.

2. Initial Moisture Content

The initial moisture content of the wood is another crucial factor affecting the drying time. Wood with higher moisture content requires more time to dry as there is more water to be removed. It is important to measure and control the initial moisture content to ensure efficient drying and prevent drying defects such as cracking and warping.

3. Thickness of the Wood

The thickness of the wood also influences the drying time in a kiln. Thicker pieces of wood take longer to dry compared to thinner ones. This is because the moisture needs to travel from the center of the wood to the surface, and thicker pieces require more time for this process. It is essential to consider the thickness of the wood when planning the drying process.

4. Kiln Environment

The environment inside the kiln is a critical factor in determining the drying time. Factors such as temperature, humidity, and airflow directly impact the rate of moisture evaporation from the wood. Higher temperatures and low humidity promote faster drying, while lower temperatures and high humidity can slow down the process. Proper control and monitoring of the kiln environment are essential for efficient drying.

5. Air Circulation

The circulation of air within the kiln affects the drying time as well. Proper air circulation ensures that the moisture is evenly distributed and removed from the wood surface. Insufficient air circulation can lead to areas of high moisture content, resulting in longer drying times and potential drying defects. It is important to design the kiln and arrange the wood in a way that allows for effective air movement.

6. Drying Schedule

The chosen drying schedule, which includes the target moisture content and the rate of drying, also plays a significant role in the overall drying time. Different wood species and sizes may require different drying schedules to achieve optimal drying without causing damage to the wood. The drying schedule should be carefully planned and adjusted based on the specific characteristics of the wood being dried.

7. Wood Treatment

In some cases, wood may require treatment before drying, which can affect the drying time. For example, certain wood treatments or preservatives may need to be applied to protect the wood from insects or fungi. These treatments may introduce additional moisture into the wood and require longer drying times to ensure the treatment is properly absorbed and the wood is adequately dried.

In summary, the drying time of wood in a kiln is influenced by various factors, including the wood species, initial moisture content, thickness, kiln environment, air circulation, drying schedule, and any pre-treatments. Understanding and carefully considering these factors is crucial for achieving efficient and successful wood drying.

Comparing Kiln Drying to Air Drying: Which is Faster?

When it comes to drying lumber, there are two primary methods used in the industry: kiln drying and air drying. Both methods have their advantages and disadvantages, but one question that often arises is which method is faster. In this section, we will compare kiln drying to air drying and analyze the drying times for each method.

Kiln drying, as the name suggests, involves using a kiln or an enclosed chamber to dry lumber. The kiln provides controlled conditions of temperature, humidity, and airflow, which accelerates the drying process. This method is highly efficient and allows for faster drying times compared to air drying.

Air drying, on the other hand, involves stacking the lumber in a well-ventilated area, typically outdoors, and allowing it to dry naturally through exposure to ambient air. This method is more cost-effective and does not require specialized equipment like kilns. However, it generally takes longer for the lumber to reach the desired moisture content.

Factors Affecting Drying Time:

The drying time for both kiln drying and air drying can vary depending on several factors:

- Wood species: Different wood species have different drying characteristics. Some species may dry faster than others.

- Initial moisture content: Wood with higher initial moisture content will take longer to dry.

- Thickness of the lumber: Thicker boards generally take longer to dry compared to thinner ones.

- Environmental conditions: Factors such as temperature, humidity, and airflow can affect drying times. Kiln drying provides precise control over these conditions, while air drying is influenced by the prevailing weather.

Drying Times:

In general, kiln drying is significantly faster than air drying. Kilns allow for precise control of temperature and humidity, creating optimal drying conditions. Depending on the factors mentioned above, kiln drying can take anywhere from a few days to a few weeks to achieve the desired moisture content.

On the other hand, air drying is a slower process and can take several months or even years. The drying time can be influenced by the wood species, initial moisture content, thickness of the lumber, and environmental conditions. It is important to note that air drying may not be suitable for certain wood species that are prone to degrade or develop defects during extended drying periods.

Conclusion:

In summary, when it comes to drying lumber, kiln drying is faster compared to air drying. Kiln drying provides controlled conditions and accelerates the drying process, allowing for shorter drying times. On the other hand, air drying is a more cost-effective method but takes significantly longer. The choice between the two methods depends on factors such as available equipment, desired drying time, and wood species. It is always recommended to consult with experts in the industry to determine which drying method is best suited for your specific needs.

Tips for Accelerating the Kiln Drying Process for Wood

Wood drying is an essential step in the lumber industry, as it helps to remove moisture from wood and enhance its stability and durability. Kiln drying is a popular method used to expedite the drying process and produce high-quality, ready-to-use wood. In this section, we will discuss some tips and techniques to accelerate the kiln drying process for wood.

1. Proper Stacking

When stacking wood in the kiln, it is important to ensure proper airflow. Avoid overcrowding the kiln, as this can hinder the circulation of hot air and slow down the drying process. Leave enough space between the stacks of wood to allow for good airflow.

2. Use Ventilation Fans

Installing ventilation fans in the kiln can help improve airflow and speed up the drying process. These fans should be strategically placed to ensure even distribution of heat and moisture removal. By promoting better airflow, the fans can accelerate the evaporation of moisture from the wood.

3. Optimize Temperature and Humidity

The temperature and humidity levels inside the kiln play a crucial role in wood drying. It is essential to monitor and control these factors to achieve efficient drying. Maintaining a stable and optimal temperature, typically between 130°F and 180°F (54°C and 82°C), along with an appropriate relative humidity level, can help accelerate the drying process.

4. Pre-Drying

Pre-drying, also known as air-drying, is a preliminary step that can significantly reduce the drying time in the kiln. By air-drying the wood to a certain moisture content before placing it in the kiln, you can remove a large portion of moisture, allowing the kiln to focus on eliminating the remaining moisture. This can help speed up the overall drying process.

5. Use Conditioning

Conditioning is a technique used towards the end of the kiln drying process to equalize the moisture content of the wood and minimize stress. It involves holding the wood at a specific temperature and humidity level for an extended period. Conditioning helps to prevent shrinkage, warping, and other defects that may occur due to rapid moisture loss.

6. Monitor Moisture Content

Regularly monitoring the moisture content of the wood during the kiln drying process is vital. This can be done using moisture meters or by weighing samples of wood. By tracking the moisture content, you can determine when the wood has reached the desired moisture level and is ready for use.

7. Proper Ventilation

After the wood has been dried in the kiln, it is essential to provide proper ventilation to prevent reabsorption of moisture. Stacking the dried wood in a well-ventilated area with good airflow will help maintain its dryness and prevent any rehydration.

In summary, accelerating the kiln drying process for wood requires careful attention to stacking, ventilation, temperature, humidity, and moisture content. By implementing these tips and techniques, you can effectively reduce drying time and produce high-quality, dry wood for various applications.

FAQs

How long does it take to kiln dry wood?

The time it takes to kiln dry wood depends on various factors such as the type of wood, thickness of the lumber, and the moisture content. Generally, it can take anywhere from a few days to several weeks to kiln dry wood.

Conclusion:

In conclusion, kiln drying wood is a highly efficient and time-saving method of removing moisture from timber. The precise amount of time it takes to kiln dry wood depends on various factors, such as the type of wood, its thickness, and the humidity levels. However, on average, the process can take anywhere from a few days to several weeks.

By utilizing controlled heat and air circulation, kiln drying ensures that the wood is dried evenly and thoroughly, resulting in improved stability, reduced risk of shrinkage or warping, and increased durability. Whether you are a furniture maker, construction professional, or woodworking enthusiast, kiln drying offers numerous benefits in terms of time, cost, and quality of the final product.

Investing in kiln-dried wood not only saves time during the drying process but also reduces the risk of using wood that may still contain excessive moisture. This not only ensures optimal performance but also enhances the overall finish of your project. So, consider kiln-dried wood as your preferred choice for all your woodworking needs.