Learning how to cut square holes in wood is a valuable skill for any DIY enthusiast or woodworking hobbyist. Whether you’re creating custom furniture or installing a door hinge, having the ability to cut precise square holes can make a world of difference in your projects.

One popular method for cutting square holes in wood is by using a chisel and mallet. This traditional technique requires some practice and precision, but it can produce clean and accurate results.

Another option is to use a router with a square hole cutting attachment. This power tool makes the process faster and more efficient, especially for larger projects.

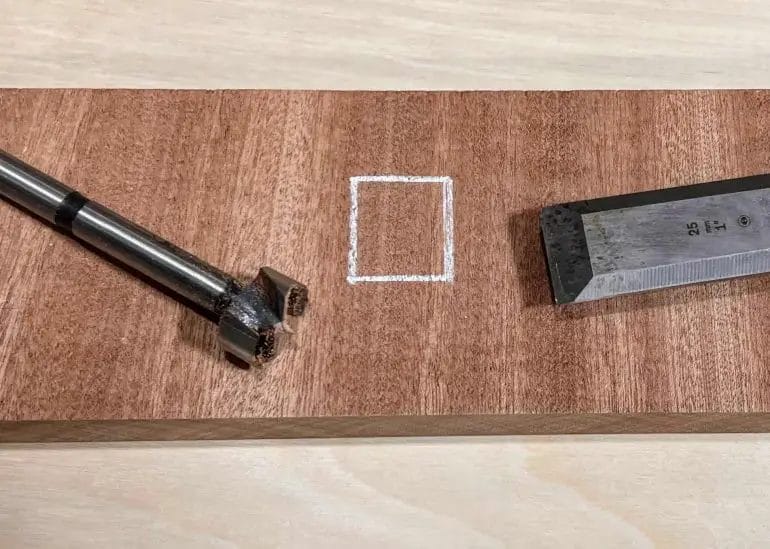

When cutting square holes, it’s important to measure and mark the desired dimensions carefully. Planning ahead and using the right tools will help you achieve professional-looking results in your woodworking projects.

Step-by-Step Guide to Cutting Square Holes in Wood

Woodworking projects often require precise cuts and shapes to achieve the desired outcome. One such task is cutting square holes in wood, which can be a bit challenging if you don’t have the right tools or technique. In this guide, we will walk you through the step-by-step process of cutting square holes in wood, ensuring a clean and accurate result.

Tools and Materials You Will Need:

- Wood material

- Pencil

- Tape measure

- Chisel set

- Drill

- Forstner bit

- Mallet

- Router (optional)

- Clamps

- Safety goggles

Step 1: Measure and Mark

Start by measuring and marking the dimensions of the square hole on the wood surface. Use a tape measure to ensure accurate measurements. Mark the corners of the square with a pencil.

Step 2: Drill Pilot Holes

Next, use a drill with a small pilot bit to create pilot holes at each corner of the square. These pilot holes will serve as a guide for the chisel and help prevent splitting or splintering of the wood.

Step 3: Create Chisel Outlines

Using a chisel, carefully connect the pilot holes by removing the wood between them. Start by making shallow cuts along the marked lines, gradually increasing the depth until you reach the desired depth for the square hole.

Step 4: Remove Waste Material

Once the chisel outlines are complete, use the chisel to remove the waste material within the square. Work slowly and carefully to ensure clean and precise cuts. It’s important to maintain the perpendicularity of the walls of the square hole.

Step 5: Smooth the Edges

After removing the waste material, use the chisel or sandpaper to smooth the edges of the square hole. This will ensure a professional-looking finish and prevent any rough edges that could cause splinters.

Optional Step: Use a Router

If you have a router and prefer a more efficient method, you can use a router with a straight bit to cut square holes in wood. Set the depth of the router bit to match the desired depth of the hole and carefully follow the marked lines. This method may require additional clamping to secure the wood.

Step 6: Test the Fit

Once the square hole is cut, test the fit by inserting the desired object or component. Make any necessary adjustments to ensure a proper fit and alignment.

Step 7: Sand and Finish

Lastly, sand the entire surface of the wood to smooth out any imperfections and achieve a polished finish. Apply a finish of your choice to protect the wood and enhance its appearance.

Summary

Cutting square holes in wood requires precision, patience, and the right tools. By following this step-by-step guide, you can confidently tackle this woodworking task and achieve accurate and clean square holes for your projects. Remember to prioritize safety by wearing goggles and working slowly and carefully. With practice, cutting square holes will become a skill you can master.

Tips and Techniques for Achieving Clean Square Holes in Wood

Woodworking projects often require the creation of square holes for various purposes such as joinery, installing hardware, or creating mortises. Achieving clean and precise square holes in wood can be challenging, but with the right techniques and tools, it can be accomplished with ease. In this section, we will discuss some tips and techniques that will help you achieve clean square holes in wood.

1. Marking and Layout

Before you start drilling or chiseling, it is crucial to carefully mark and layout the location of the square hole. Use a combination square or a marking gauge to mark the sides and ends of the hole. Ensure that your layout lines are accurate and square to the wood surface.

2. Using a Drill Press

If you have access to a drill press, it can greatly assist in creating clean and precise square holes. Start by drilling a series of holes within the marked area using a drill bit slightly smaller than the width of the desired hole. Then, use a chisel to remove the waste material and square up the hole. Take your time and make multiple passes until you achieve the desired depth and squareness.

3. Chisel and Mallet Technique

When working without a drill press, you can achieve clean square holes using a chisel and mallet technique. Start by removing most of the waste material by drilling a series of overlapping holes within the marked area using a drill bit slightly larger than the width of the desired hole. Then, use a sharp chisel and a mallet to clean up the edges and square up the hole. Work slowly and carefully, making small adjustments with each pass.

4. Router and Template Method

Another effective technique for creating clean square holes in wood is using a router and template method. Start by creating a template with the exact dimensions of the square hole you want to create. Secure the template to the wood surface and use a router with a straight bit to remove the waste material. The template will guide the router, ensuring a clean and precise hole.

5. Hollow Chisel Mortiser

A hollow chisel mortiser is a specialized tool designed specifically for creating square holes, particularly for joinery and mortises. This machine combines the drilling and chiseling processes into a single step, resulting in quick and accurate square holes. If you frequently work with square holes, investing in a hollow chisel mortiser can save you time and effort.

6. Finishing and Smoothing

Once you have achieved the desired square hole, it is essential to finish and smooth the hole to ensure a clean and professional look. Use a file or sandpaper to smooth any rough edges or surfaces. This will not only improve the aesthetics but also prevent splintering or snagging when inserting hardware or joinery.

In summary, achieving clean square holes in wood requires proper marking and layout, as well as the use of appropriate tools and techniques. Whether you choose to use a drill press, chisel and mallet, router and template, or a hollow chisel mortiser, the key is to work slowly, carefully, and make small adjustments as needed. With practice and patience, you will be able to create clean and precise square holes in your woodworking projects.

Common Mistakes to Avoid When Cutting Square Holes in Wood

Cutting square holes in wood can be a challenging task, but with the right techniques and tools, it can be accomplished successfully. However, there are some common mistakes that people often make when attempting this type of woodworking project. In this section, we will discuss these mistakes and provide tips on how to avoid them.

1. Incorrect Measurement

One of the most common mistakes when cutting square holes in wood is getting the measurements wrong. It is crucial to measure and mark the correct dimensions before making any cuts. If the measurements are inaccurate, the hole may end up too big or too small, resulting in a poor fit for the intended component.

To avoid this mistake, take your time to measure accurately and double-check your measurements before cutting. Use a reliable measuring tool, such as a tape measure or a square, to ensure precision.

2. Not Using a Guide

Another mistake is attempting to cut a square hole freehand without using a guide. This can lead to uneven cuts and an ill-fitting hole. Using a guide, such as a square or a jig, can help you achieve straight and precise cuts.

Before cutting, secure the guide in place and use it as a reference point for your saw or router. This will help you maintain a straight line and ensure that the sides of the hole are perpendicular to the surface of the wood.

3. Rushing the Cutting Process

Cutting square holes in wood requires patience and precision. One common mistake is rushing through the cutting process, which can result in sloppy and inaccurate cuts. It is essential to take your time and make slow, deliberate cuts to achieve the desired outcome.

Start by making small initial cuts and gradually increase the depth as needed. This will help you maintain control and prevent the wood from splintering or cracking.

4. Neglecting to Secure the Wood

When cutting square holes in wood, it is crucial to secure the wood properly. Neglecting to do so can lead to the wood shifting or moving during the cutting process, resulting in uneven cuts or damage to the wood.

Before making any cuts, secure the wood firmly in place using clamps or a vice. This will ensure stability and prevent any unwanted movement.

5. Using Dull Tools

Using dull tools is a common mistake that can affect the quality of the cuts when cutting square holes in wood. Dull blades can cause the wood to splinter or tear, resulting in rough edges and an imprecise hole.

Make sure to use sharp, high-quality tools designed for cutting wood. Regularly check and maintain the sharpness of your blades to ensure clean and accurate cuts.

6. Overlooking Safety Precautions

Safety should always be a top priority when working with tools and machinery. Neglecting safety precautions can lead to accidents and injuries. When cutting square holes in wood, it is essential to wear appropriate safety gear, such as safety glasses and gloves.

Additionally, be cautious of your surroundings and ensure that the work area is clear of any obstructions. Always follow the manufacturer’s instructions for operating tools and machinery.

Summary

When cutting square holes in wood, it is important to avoid common mistakes that can impact the quality and accuracy of the cuts. Take your time to measure accurately, use a guide for straight cuts, and secure the wood properly. Avoid rushing the cutting process, use sharp tools, and prioritize safety precautions. By following these tips and techniques, you can successfully cut square holes in wood for your woodworking projects.

Creative Uses for Square Holes in Woodworking Projects

Woodworking is a craft that allows for endless creativity and exploration. From building furniture to crafting intricate designs, there are numerous ways to put your woodworking skills to use. One interesting technique that adds a unique touch to woodworking projects is the use of square holes. While round holes may be more common, square holes can bring a distinct aesthetic and functionality to your creations.

1. Joinery

One of the primary uses of square holes in woodworking is for joinery purposes. Square holes can be used in conjunction with corresponding square pegs or tenons to create strong and secure connections between different pieces of wood. This method, known as mortise and tenon joinery, has been used for centuries and is favored for its durability and stability. Whether you’re constructing a table, chair, or cabinet, the use of square holes and tenons can enhance the overall strength and longevity of your woodworking projects.

2. Decorative Elements

Square holes can also serve as decorative elements in your woodworking projects. By strategically placing square openings in your designs, you can create visual interest and add a unique flair to your pieces. These openings can be filled with contrasting materials such as glass, metal, or even other wood types, creating a captivating focal point. Whether you incorporate square holes into the legs of a table, the backrest of a chair, or the panels of a cabinet, they can elevate your woodworking projects to a whole new level of artistry.

3. Cable Management

In this digital age, the need for effective cable management has become increasingly important. Square holes can be utilized to incorporate cable management solutions into your woodworking projects. By creating square holes in the back or sides of furniture pieces, you can discreetly route cables and wires, keeping them organized and out of sight. This not only enhances the aesthetics of your creations but also ensures functionality and convenience for users.

4. Storage Solutions

Square holes can be an excellent way to incorporate storage solutions into your woodworking projects. By creating custom-sized square openings, you can design compartments that perfectly fit specific items. For example, you could build a wall-mounted shelf with square holes to hold wine bottles, or a desk organizer with square compartments for pens and stationery. The versatility of square holes allows for endless possibilities when it comes to creating functional and stylish storage options.

5. Ventilation

Another creative use for square holes in woodworking is ventilation. By strategically placing square openings in your designs, you can improve airflow and prevent the buildup of heat or moisture. This is particularly beneficial for items such as cabinets, drawers, or even speaker enclosures. The addition of square ventilation holes not only enhances the functionality of your woodworking projects but also ensures their longevity by preventing potential damage caused by inadequate airflow.

In summary, square holes offer a range of creative possibilities in woodworking projects. Whether used for joinery, decorative elements, cable management, storage solutions, or ventilation, square holes can add both functionality and aesthetic appeal to your creations. So why not experiment with this unique technique and see how it can elevate your woodworking skills and projects to new heights?

FAQs

1. How can I cut square holes in wood?

To cut square holes in wood, you can use a variety of methods such as a chisel and mallet, a router with a square bit, or a scroll saw. Start by marking the dimensions of the hole on the wood, then carefully remove the wood using your chosen method.

2. What tools do I need to cut square holes in wood?

To cut square holes in wood, you will typically need tools such as a chisel, mallet, router with a square bit, or a scroll saw. The specific tools required may vary depending on the size and depth of the hole you need to cut.

3. Are there any tips for cutting square holes in wood?

When cutting square holes in wood, it’s important to take certain precautions. Use sharp tools to ensure clean cuts and make sure to work slowly and precisely. Additionally, consider practicing on a scrap piece of wood before attempting the final cut to ensure accuracy and avoid any mistakes.

Conclusion

In conclusion, cutting square holes in wood can be achieved with the right tools and techniques. By using a combination of a chisel, a drill, and a jigsaw, you can create precise square holes for various woodworking projects.

Remember to measure and mark the dimensions of the hole accurately before starting the cutting process. Take your time and work slowly and steadily to ensure clean and accurate cuts.

Additionally, it is important to wear protective gear such as safety goggles and gloves to prevent any potential injuries. With practice and patience, you can become proficient in cutting square holes in wood and add a unique touch to your woodworking projects.