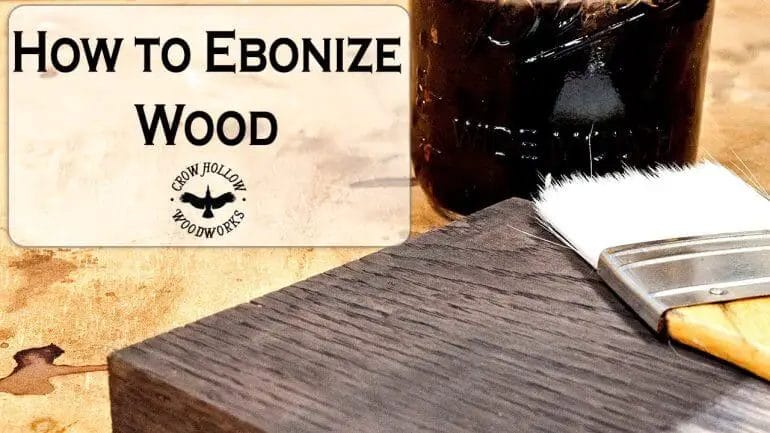

Ebonizing wood is a popular technique used to give wooden surfaces a dark and rich black color. It involves the application of a special solution or stain that reacts with the tannins in the wood to create the desired effect. Ebonized wood can add a touch of elegance and sophistication to furniture, floors, or any wooden project. In this guide, we will explore different methods and tools to help you achieve the perfect ebony finish on your wood.

Choosing the Right Wood Species for Ebonizing

When it comes to ebonizing wood, selecting the right wood species is essential to achieve the desired results. Ebonizing is a technique used to darken the wood and give it a rich black appearance, similar to ebony wood. While almost any type of wood can be ebonized, some species yield better results than others. In this section, we will explore the factors to consider when choosing the wood species for ebonizing.

1. Porosity

One of the key factors to consider is the porosity of the wood species. Ebonizing works best on woods with an open grain structure. Hardwoods like oak, ash, or walnut are popular choices due to their porous nature. The open pores of these woods allow the ebonizing solution to penetrate deeply and create a darker finish.

On the other hand, woods with a closed grain structure, such as maple or cherry, are less suitable for ebonizing. The tighter grain makes it challenging for the ebonizing solution to penetrate effectively, resulting in a lighter and less uniform color.

2. Tannin Content

The tannin content of the wood also plays a crucial role in ebonizing. Tannins are natural compounds found in various wood species and can react with the ebonizing solution to produce a darker color. Woods with a higher tannin content tend to achieve better ebonizing results.

Examples of wood species with high tannin content include oak, walnut, and mahogany. These woods naturally contain more tannins, which enhance the ebonizing process. In contrast, woods like pine or poplar have lower tannin content and may require additional steps or treatments to achieve a satisfactory ebonized finish.

3. Surface Smoothness

The smoothness of the wood surface is another factor to consider when selecting a wood species for ebonizing. The smoother the surface, the more evenly the ebonizing solution will be absorbed and distributed, resulting in a uniform black color.

Woods with naturally smoother surfaces, such as maple or cherry, may require additional steps to prepare the surface before ebonizing. Sanding the wood to a finer grit and using wood conditioners or pre-stain sealers can help improve the overall results and ensure a more even ebonized finish.

4. Test and Experiment

It’s always a good idea to test and experiment with different wood species before committing to a large project. Some species may yield surprising results and provide unique variations of black when ebonized.

Before ebonizing the entire piece, test the ebonizing solution on a small, inconspicuous area of the wood to observe how it reacts and whether it achieves the desired color. This allows you to make adjustments or choose an alternative wood species if needed.

5. Personal Preference

Ultimately, personal preference plays a significant role in choosing the right wood species for ebonizing. While certain woods may be considered optimal for ebonizing, there are no strict rules. Some individuals may prefer the subtle variations and character of ebonized pine, while others may opt for the deep, rich color of ebonized walnut.

Consider the desired aesthetic, the overall project design, and the natural characteristics of the wood when making your decision. Keep in mind that ebonizing is a transformative process, and the final result will depend on the combination of the wood species, ebonizing solution, and finishing techniques used.

In summary, when choosing the right wood species for ebonizing, consider the porosity, tannin content, surface smoothness, conduct tests, and take personal preferences into account. By selecting the appropriate wood species, you can achieve a stunning ebonized finish that enhances the beauty of your woodworking projects.

Step-by-Step Guide to Ebonizing Wood: Tools and Materials Needed

Ebonizing wood is a technique that allows you to give your wooden furniture or projects a dark, ebony-like finish. This process involves using a solution that reacts with the tannins in the wood to create a deep, rich black color. If you’re interested in trying this technique, here’s a step-by-step guide to help you get started:

Materials Needed:

- Wooden object or furniture piece

- Fine-grit sandpaper

- Clean, lint-free cloth

- Ebonizing solution (such as iron acetate or black tea)

- Container for the ebonizing solution

- Brush or cloth for applying the solution

- Protective gloves

- Protective eyewear

- Protective mask

Step 1: Prepare the Wood

Start by preparing the wood surface for the ebonizing process. Use fine-grit sandpaper to smooth out any imperfections and ensure a clean and even surface.

Step 2: Clean the Wood

Wipe down the wood with a clean, lint-free cloth to remove any dust or debris. This will help the ebonizing solution adhere better to the surface.

Step 3: Prepare the Ebonizing Solution

If you’re using iron acetate, mix equal parts white vinegar and steel wool in a glass jar and let it sit for at least 24 hours. If you prefer using black tea, brew a strong pot of tea and let it cool.

Step 4: Apply the Ebonizing Solution

Put on your protective gloves, eyewear, and mask to ensure your safety during the application process. Dip a brush or cloth into the ebonizing solution and apply it evenly onto the wood surface, following the grain. Make sure to cover the entire area you want to ebonize.

Step 5: Allow the Solution to Dry

Once you’ve applied the ebonizing solution, let it dry completely. This may take several hours or even overnight, depending on the type of solution used and the humidity levels in your area.

Step 6: Sand and Repeat (Optional)

If desired, you can lightly sand the surface with fine-grit sandpaper to remove any raised wood fibers or rough spots. Repeat the ebonizing process by applying another coat of the solution and allowing it to dry.

Step 7: Seal the Wood

After the ebonizing solution has dried completely, you can choose to seal the wood with a clear topcoat or leave it as is for a more rustic look. Applying a sealant will help protect the ebonized finish and enhance its longevity.

Summary

Ebonizing wood is a great way to give your wooden projects a stunning and unique black finish. By following this step-by-step guide and using the right tools and materials, you’ll be able to achieve a beautiful ebonized look for your furniture or decorative items.

Remember to always prioritize safety by wearing protective gear and working in a well-ventilated area. With a little patience and attention to detail, you’ll be able to create impressive ebonized wood pieces that are sure to make a statement in any space.

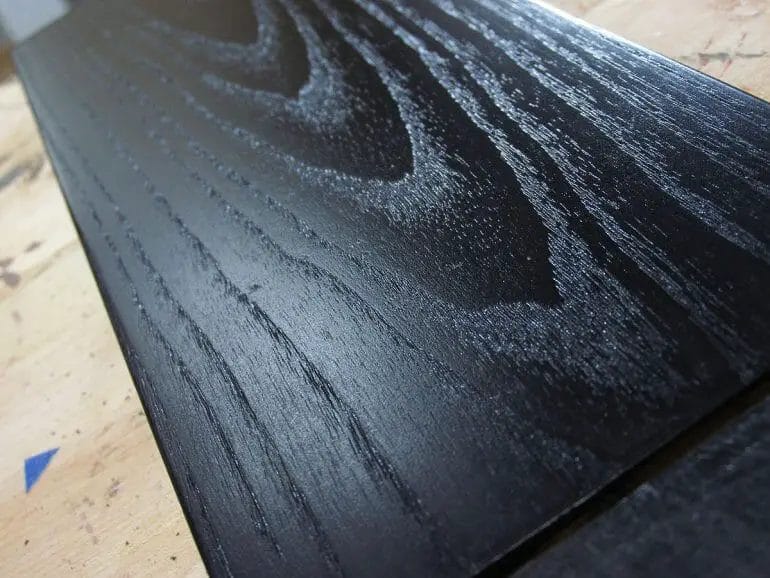

Tips for Creating a Smooth and Even Ebonized Finish

Creating a smooth and even ebonized finish on wood can be a challenging task. However, with the right techniques and tools, you can achieve a stunning, dark finish that enhances the natural beauty of the wood. Here are some tips to help you create a smooth and even ebonized finish:

1. Prepare the Wood Surface

Before you begin the ebonizing process, it is essential to prepare the wood surface properly. Start by sanding the wood with fine-grit sandpaper to remove any imperfections, such as scratches or dents. Make sure to sand in the direction of the wood grain for a smooth finish.

2. Test the Ebonizing Solution

It is crucial to test the ebonizing solution on a small, inconspicuous area of the wood before applying it to the entire surface. This will help you determine the desired color and ensure that the solution reacts well with the wood species.

3. Apply the Ebonizing Solution

Once you have selected the ebonizing solution that suits your preference, apply it to the wood using a brush, sponge, or cloth. Make sure to follow the manufacturer’s instructions for the best results. Apply the solution evenly, working in small sections, and avoid overlapping strokes to prevent streaks or uneven coloring.

4. Allow Sufficient Drying Time

After applying the ebonizing solution, allow sufficient drying time. This will ensure that the color develops evenly and prevents smudging or damage to the finish. Follow the manufacturer’s instructions for the recommended drying time.

5. Sand and Seal the Wood

Once the ebonizing solution has dried, lightly sand the surface with fine-grit sandpaper to smooth out any raised grain or imperfections. After sanding, apply a clear sealer or topcoat to protect the ebonized finish and enhance its durability. Make sure to choose a sealer that is compatible with the ebonizing solution used.

6. Maintain and Care for the Ebonized Finish

To keep the ebonized finish looking its best, it is essential to maintain and care for it properly. Avoid using abrasive cleaners or harsh chemicals that can damage the finish. Instead, use a soft cloth or mild soap and water to clean the surface. Additionally, periodically apply a wax or polish specifically designed for ebonized finishes to restore shine and protect the wood.

In summary, achieving a smooth and even ebonized finish requires careful preparation, testing, and application techniques. By following these tips and using quality materials, you can create a stunning dark finish that adds elegance to your wood projects.

Maintaining and Caring for Ebonized Wood Furniture

Ebonized wood furniture is known for its rich, dark appearance that adds sophistication and elegance to any space. However, like any other type of furniture, it requires regular maintenance and care to ensure its longevity and beauty. In this section, we will discuss some essential tips and guidelines for maintaining and caring for ebonized wood furniture.

1. Dusting and Cleaning

Regular dusting is crucial to prevent the buildup of dirt and grime on your ebonized wood furniture. Use a soft, lint-free cloth or a microfiber duster to gently remove dust from the surface. Avoid using abrasive materials or harsh chemicals that can damage the finish.

When it comes to cleaning ebonized wood furniture, it’s recommended to use a mild, non-abrasive cleaner specifically formulated for wood. Dilute the cleaner with water according to the instructions and apply it to a soft cloth. Gently clean the furniture in the direction of the grain, and remember to dry the surface thoroughly to prevent moisture damage.

2. Avoid Direct Sunlight

Ebonized wood furniture is susceptible to fading and discoloration when exposed to direct sunlight for prolonged periods. To prevent this, place your furniture away from windows or use curtains or blinds to block the sunlight. If it’s not possible to avoid direct sunlight entirely, consider using UV-blocking window film or applying a protective coating to the furniture.

3. Use Coasters and Mats

To protect the surface of your ebonized wood furniture from heat, moisture, and scratches, it’s advisable to use coasters, placemats, or trivets. These protective accessories create a barrier between the furniture and hot or wet objects, preventing potential damage. Additionally, using felt or rubber pads under objects that are frequently moved can help prevent scratches on the furniture’s surface.

4. Avoid Extreme Temperatures and Humidity

Ebonized wood furniture should be kept in an environment with stable temperature and humidity levels. Avoid placing the furniture near heating vents, radiators, or air conditioning units, as extreme temperature fluctuations can cause the wood to warp or crack. Similarly, high humidity levels can lead to swelling or warping of the wood, while low humidity can cause it to dry out and crack. Use a humidifier or dehumidifier to maintain a suitable humidity level in the room.

5. Annual Maintenance and Inspection

Performing annual maintenance and inspection is essential to identify and address any issues or damage before they worsen. Inspect the furniture for any loose joints, cracks, or signs of wear. Tighten loose screws or replace them if necessary. If you notice any damage or scratches on the ebonized finish, you can use a touch-up pen or a furniture marker specifically designed for wood to repair minor imperfections.

In summary, maintaining and caring for ebonized wood furniture involves regular dusting, using non-abrasive cleaners, avoiding direct sunlight, using coasters and mats, controlling temperature and humidity levels, and performing annual maintenance and inspections. By following these guidelines, you can preserve the beauty and longevity of your ebonized wood furniture for years to come.

FAQs

Q: How to ebonize wood?

To ebonize wood, first, prepare the wood surface by sanding it to remove any existing finish. Then, apply a wood conditioner to ensure an even stain absorption. Next, apply a black wood stain or a mixture of vinegar and steel wool solution. Let it dry and repeat the process if a darker color is desired. Finally, seal the wood with a clear finish.

Conclusion

In conclusion, ebonizing wood is a fantastic technique that can transform the look of any piece of furniture or object. By using a combination of natural ingredients such as vinegar and steel wool, you can create a stunning ebony black finish that adds depth and character to your woodwork. This versatile and affordable method allows you to achieve a unique and sophisticated aesthetic, whether you’re working on a large project or a small DIY endeavor. Ebonized wood can bring a touch of elegance and drama to any space, making it a popular choice for designers and craftsmen alike. So why not try ebonizing wood and elevate your woodworking projects to a whole new level?