A lap joint is a type of joinery that attaches two pieces of wood together by overlapping them and securing them at the overlap point, usually with glue or screws. They are one of the simplest, yet most useful types of joints and they have been used for centuries as a way to create strong connections.

There are several different types of lap joints, which vary in their level of complexity. This blog post will discuss the various types and how to use them properly so that your project turns out beautifully!

Types of Lap Joints

The primary two types of lap joints are full-lap and half-lap joints. And, cross lap joint, mitered lap joint, dovetail lap joint, etc are just a few of the most frequent types of Lap Joints.

Full Lap Joint

A full lap joint is a type of joint in which two boards are connected edge-to-edge to form a flat surface. In other words, the two boards’ ends are overlapped. If you have two 1-inch thick timbers, a full lap joint would be 2-inch thick.

The joint is strengthened by driving dowel pins through it before assembling, or by applying glue before assembling. This type of joint is useful for adding strength to corners where boards meet.

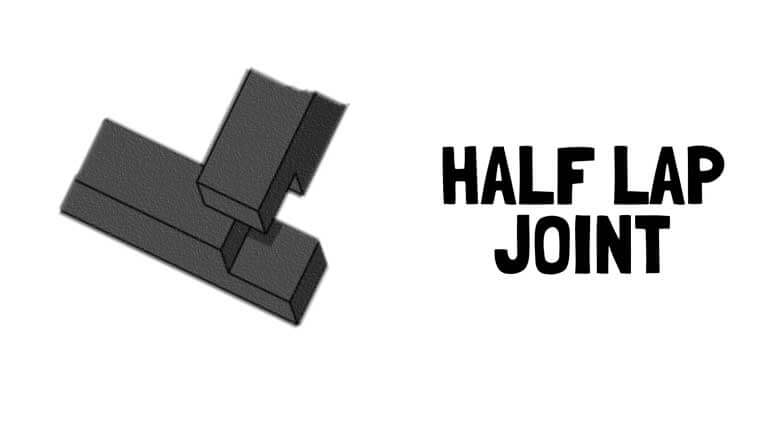

Half-lap Joint

The half-lap joint is a kind of lap joint where one piece of wood is overlapping the other. Before they overlap, the portions of wood that will overlap are thinned by 50 percent on the Half-Lap Joint.

It works by attaching two lengths of wood at an angle to one another and then fastening them together with nails, screws, or glue.

This joint is used in the construction of cabinets and tables because it’s able to span distances greater than other types of joints and still provide solid support.

Cross Lap Joint

A cross lap joint is a form of the half-lap joint that consists of two pieces that are cut at a right angle to each other and then lapped or folded together in the middle of one or both parts. It can be glued and pegged together or reinforced with screws and nails.

Cross lap joints are used mainly in framing types of work. The advantage of this joint is that it has a lot of glue surface area, which increases the joint’s strength.

And the disadvantage of using this technique is that it does not allow you to insert large parts into it. Plus, it takes more skill and measuring to make the notch with this method.

Mitered Half Lap Joint

A mitered half-lap joint is best for joining workpieces that are of the same thickness. To make this joint, cut two equally sized pieces of wood (usually) with 45-degree angles at each end. Fit the angled edges of one piece into the opposing angled edges of the other and secure them together by using glue, nails or screws.

The mitered half-lap joint can be used for joining moldings in cases where it is not possible to use a rabbeted lap, but this joint suffers from reduced strength in compression so it should never be used in load-bearing joints.

Dovetail Lap Joint

One of the most common lap joints is a dovetail lap joint. Dovetail lap joint employs a projecting tenon on one end of the joined pieces. The projecting tenon is shaped like a dovetail, hence the name of the joint. The other end of the joint does not have a projecting tenon and instead has a mortise, which may be square or rectangular in shape.

This type of joint makes use of two mating dovetails that interlock with each other to form a secure, sturdy joint. This joint is often found in fine furniture, musical instruments, and other woodworking projects where strength is needed for holding two pieces together.

A dovetail lap joint is used when you want to have a large surface contact area between two pieces. It can also be used to join pieces of different lengths together at 90 degrees.

If you don’t want to create your own dovetail joints, there are several dovetail templates or jigs available to buy. Dovetail jig will help you to create your joints easily.

Edge Lap

The edge lap joint (also known as edge cross lap) is an overlapping joint in which two boards are overlap edge to edge. The boards are cut to the same width, and one edge of each board overhangs the other by 1/8″ to 3/4″. One edge piece is then nailed or screwed to the other.

When these boards are joined together, they form a neat corner because both edges are beveled on the inside corners. They are usually used for making box compartment dividers and egg crates.

End Lap

One of the most popular joints used in woodworking is the end lap joint. An end lap joint is a type of lap joint that forms a join between two pieces by the end of one fitting into another. The pieces are then joined together with a fastener that runs through the whole length of both boards.

One example of an end lap joint is a pocket hole joint. A pocket hole joint is created by drilling a hole at one end of one board and another hole at the opposite end of the second board so that they line up with each other. A screw is then used to join them together.

Additional Resource:

- Lap Joint Pros and Cons – Detail Explanation

- Different Types of Tongue and Groove Joints

Conclusion:

The types of lap joints are endless. Learning which joint to use for your project will take some research and practice, but it will save you time in the long run.

Lap joints can be used for joining two pieces together end-to-end or edge-to-edge; they can also be mitered or dovetail shapes depending on how much strength is needed.

The best way to learn about these different types of joints is by reading articles like this one that provide all the information you need so that you know what type of joint fits with which job. Plus, practice them regularly to understand the joinery better.

So, which type have you tried out before? What other ways do people join wood boards together? Share your thoughts below!