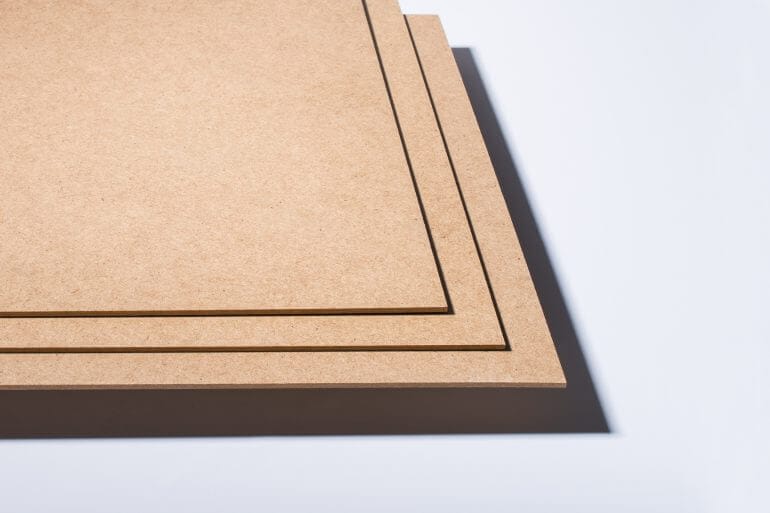

HDF wood, also known as High-Density Fiberboard, is a versatile and durable engineered wood product that is made from compressed wood fibers. It is known for its strength and resistance to warping and cracking, making it a popular choice in construction and furniture manufacturing.

HDF wood is made by breaking down wood fibers into fine particles and then binding them together using heat and pressure. This process results in a dense and uniform wood material that is smooth, hard, and highly stable.

Due to its high density, HDF wood is often used for applications that require strength and durability, such as flooring, cabinets, and shelving. It is also a preferred choice for painting and laminating due to its smooth surface and ability to hold finishes well.

Additionally, HDF wood is an environmentally friendly choice as it is often made from recycled wood fibers and does not require the harvesting of new trees. Its durability and long lifespan also contribute to its sustainable nature.

Whether you are looking for a material for your home renovation or furniture project, HDF wood offers a reliable and cost-effective option that combines strength, durability, and sustainability.

Common uses and applications of HDF wood

HDF (High-Density Fiberboard) wood is a versatile material that finds application in a wide range of industries and projects. Due to its unique characteristics and properties, HDF wood has become increasingly popular in various construction, furniture, and interior design applications. In this section, we will explore some of the common uses and applications of HDF wood.

Furniture Manufacturing

HDF wood is widely used in the manufacturing of furniture, particularly for the construction of cabinets, shelves, and other storage units. Its high-density nature provides excellent stability and durability, making it an ideal choice for furniture that needs to withstand heavy use. HDF wood can be easily shaped and finished, allowing furniture manufacturers to create intricate designs and achieve a smooth, polished appearance.

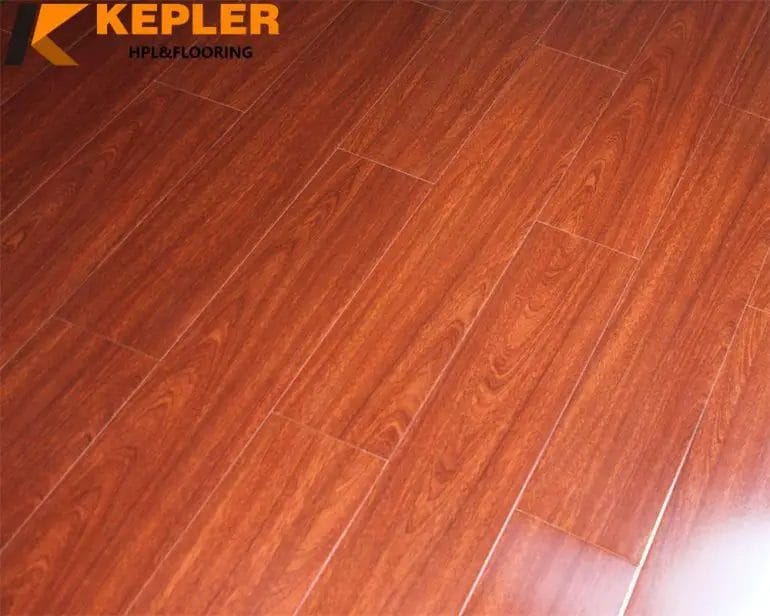

Flooring

HDF wood is commonly used as a core material for laminate flooring. Its high density and strength make it a perfect substrate for the top decorative layer and the wear-resistant overlay. HDF wood provides excellent stability and resistance to moisture, ensuring the longevity of the flooring. Additionally, it offers good sound insulation properties, making it a preferred choice for residential and commercial flooring applications.

Doors and Paneling

HDF wood is also extensively used in the manufacturing of doors, especially interior doors. Its smooth surface allows for easy paint or veneer application, providing a seamless, finished look. HDF doors are known for their superior dimensional stability, resistance to warping, and longevity. HDF wood is also used for wall paneling and wainscoting, adding a touch of elegance and durability to interior spaces.

Cabinetry and Shelving

HDF wood is a popular choice for cabinetry and shelving due to its strength, durability, and versatility. It is commonly used for kitchen cabinets, bathroom vanities, and storage units. HDF wood can be easily customized to fit specific design requirements and can withstand the weight of heavy items without sagging or warping. Its smooth surface allows for easy cleaning and maintenance, making it an ideal material for practical and aesthetically pleasing cabinetry and shelving solutions.

Exhibition Booths and Displays

HDF wood is frequently used in the construction of exhibition booths and displays due to its lightweight yet sturdy nature. It can be easily cut, shaped, and assembled to create custom structures and designs. HDF wood is often used as a base material for attaching graphics, signage, and other promotional materials. Its smooth and consistent surface provides an excellent backdrop for showcasing products and attracting attention at trade shows and exhibitions.

Other Applications

In addition to the aforementioned uses, HDF wood is also employed in various other applications, including wall partitions, decorative elements, speaker enclosures, and packaging materials. Its versatility, strength, and cost-effectiveness make it a preferred choice for many industries and projects.

In summary, HDF wood is a highly versatile material used in a wide range of applications, including furniture manufacturing, flooring, doors, cabinetry, exhibition booths, and more. Its unique properties, such as high density, durability, and ease of customization, make it an excellent choice for numerous projects in construction, design, and manufacturing.

How to Select and Purchase High-Quality HDF Wood

When it comes to selecting and purchasing HDF (High-Density Fiberboard) wood, it is important to consider various factors to ensure that you are getting a high-quality product. HDF wood is widely used in construction, furniture making, and various other applications due to its durability and versatility. In this section, we will discuss the key points to keep in mind when choosing and buying HDF wood.

1. Determine Your Requirements

Before you start looking for HDF wood, you need to determine your specific requirements. Consider the purpose for which you are purchasing the wood, whether it is for flooring, cabinetry, or any other project. This will help you select the right grade and thickness of HDF wood.

2. Check the Density Rating

The density of HDF wood plays a crucial role in its quality and durability. Higher density HDF boards are more robust and resistant to moisture, making them suitable for areas with high humidity levels. Check the density rating of the HDF wood you are considering and opt for boards with a higher density for better performance.

3. Look for Moisture Resistance

HDF wood with good moisture resistance is essential, especially if you are using it in areas prone to moisture, such as kitchens or bathrooms. Look for HDF boards that have been treated with water-resistant coatings or have a moisture-resistant core. This will help prevent swelling, warping, or damage due to moisture absorption.

4. Consider the Thickness and Dimension

The thickness and dimension of the HDF wood should align with your project requirements. Thicker HDF boards are more rigid and can provide better stability, while thinner boards are suitable for applications where flexibility is needed. Additionally, ensure that you choose boards with accurate dimensions to avoid any issues during installation.

5. Assess the Surface Finish

The surface finish of HDF wood can significantly impact its appearance and overall aesthetic appeal. Look for boards with a smooth, even finish that is free from any blemishes, scratches, or imperfections. This will ensure a high-quality and visually pleasing end result.

6. Check for Certifications

Opt for HDF wood that has been certified by reputable organizations such as the Forest Stewardship Council (FSC) or the Sustainable Forestry Initiative (SFI). These certifications indicate that the wood has been sourced sustainably and meets specific environmental and quality standards.

7. Compare Prices and Quality

Lastly, compare prices and quality from different suppliers before making a purchase. Keep in mind that high-quality HDF wood may come at a slightly higher price, but it will offer better durability and longevity. Consider your budget and choose a supplier that offers a balance between quality and affordability.

By following these guidelines, you can confidently select and purchase high-quality HDF wood that meets your specific requirements and ensures a long-lasting and aesthetically pleasing end result. Take your time to assess different options and consult with experts if needed to make an informed decision.

Key factors to consider before using HDF wood in a project

High Density Fiberboard (HDF) wood is a popular choice in many construction and woodworking projects due to its durability and affordability. However, before incorporating HDF wood into your project, it is important to consider several key factors to ensure its suitability and success. This article will outline the essential considerations to keep in mind before using HDF wood in your next project.

1. Strength and Durability

One of the primary factors to consider before using HDF wood is its strength and durability. HDF wood is known for its high density, which contributes to its exceptional strength and resistance to warping, swelling, and cracking. Assess the specific requirements of your project and determine whether HDF wood can withstand the expected load and environmental conditions.

2. Moisture Resistance

HDF wood offers good moisture resistance, making it suitable for use in areas prone to high humidity or moisture exposure, such as kitchens and bathrooms. However, it is important to note that while HDF wood is moisture-resistant, it is not entirely waterproof. Assess the level of moisture exposure in your project and ensure that proper sealing or coating measures are in place to protect the HDF wood.

3. Machinability

Consider the machinability of HDF wood before using it in your project. HDF wood is generally easy to work with and can be cut, shaped, and routed using standard woodworking tools. However, it is essential to use sharp cutting tools and take appropriate safety precautions to avoid splintering or damaging the HDF wood during the machining process.

4. Finishing Options

Another factor to consider is the finishing options available for HDF wood. HDF wood can be finished with paint, laminate, or veneer to achieve the desired aesthetic appeal. Take into account the look and style you want to achieve in your project and ensure that HDF wood can be successfully finished to your desired specifications.

5. Environmental Impact

Before using HDF wood, it is important to consider its environmental impact. HDF wood is typically made from recycled wood fibers and does not contribute to deforestation. However, the manufacturing process of HDF wood may involve the use of chemicals and adhesives. If environmental sustainability is a concern for your project, research the manufacturer’s practices and certifications to ensure that the HDF wood meets your environmental standards.

6. Cost

Finally, consider the cost of HDF wood in comparison to other wood options. HDF wood is often more cost-effective than solid wood, making it an attractive choice for projects with budget constraints. However, it is essential to evaluate the overall project requirements and balance cost considerations with the desired quality and performance.

Summary

When considering the use of HDF wood in your project, it is crucial to assess its strength and durability, moisture resistance, machinability, finishing options, environmental impact, and cost. By carefully evaluating these factors, you can ensure that HDF wood is the right choice for your specific project requirements, ultimately leading to a successful and long-lasting result.

Maintenance and Care Tips for HDF Wood Products

HDF (High-Density Fiberboard) is a popular choice for furniture and other wood products due to its durability, affordability, and versatility. However, like any other material, HDF wood products require proper maintenance and care to ensure their longevity and aesthetic appeal. In this section, we will discuss some essential tips to help you maintain and care for your HDF wood products.

1. Cleaning

Regular cleaning is crucial to keep HDF wood products looking their best. Start by removing any dust or debris using a soft cloth or a vacuum cleaner with a soft brush attachment. Avoid using abrasive cleaners or rough sponges as they can scratch the surface of the wood. Instead, opt for a mild detergent mixed with warm water. Gently wipe the surface using a damp cloth and then dry it immediately with a clean, dry cloth.

2. Avoid Excessive Moisture

While HDF wood products are relatively resistant to moisture compared to solid wood, it is still essential to prevent excessive exposure to water or liquid spills. Wipe up any spills immediately using a soft cloth to avoid absorption into the wood. Avoid placing HDF wood products in areas prone to high humidity or near sources of moisture, such as bathrooms.

3. Protection from Sunlight

Direct sunlight can cause the color of HDF wood products to fade over time. To protect your furniture from sun damage, position them away from windows or use window treatments such as curtains or blinds to block direct sunlight. Alternatively, you can also apply a UV protectant coating specifically designed for wooden surfaces to minimize the effects of sun exposure.

4. Use Coasters and Mats

To prevent scratches, dents, and heat damage, it is advisable to use coasters, placemats, and trivets on HDF wood surfaces. These protective accessories provide a barrier between hot objects, liquid spills, and the wood, minimizing the risk of surface damage. Always remember to lift objects instead of dragging them across HDF wood surfaces to avoid scratching.

5. Avoid Harsh Chemicals

Avoid using harsh chemicals, solvents, or abrasive cleaners on HDF wood products as they can damage the protective finish and the wood itself. Instead, opt for mild cleaning solutions or specialized wood cleaners recommended by the manufacturer. Always read and follow the instructions provided by the manufacturer when using any cleaning or maintenance products.

6. Regular Maintenance

To keep your HDF wood products in excellent condition, consider applying a high-quality furniture polish or wax every few months. This helps to restore shine, protect the wood, and minimize the appearance of scratches or scuffs. Always follow the product instructions and test in an inconspicuous area before applying to the entire surface.

7. Handle with Care

Lastly, handle HDF wood products with care to avoid accidental damage. Lift furniture instead of dragging it to prevent loosening joints or causing scratches. Use padding or soft material when moving or transporting furniture to protect the surfaces. Additionally, avoid placing heavy objects on HDF wood surfaces to prevent warping or structural damage.

By following these maintenance and care tips, you can extend the lifespan of your HDF wood products and keep them looking their best for years to come. Remember to always refer to the manufacturer’s instructions for specific care recommendations and enjoy the beauty and durability of your HDF wood furnishings.

FAQs

What is HDF wood?

HDF stands for High-Density Fiberboard. It is a type of engineered wood product made from compressed wood fibers and resin. HDF wood is known for its high strength, durability, and resistance to moisture and warping. It is commonly used for furniture, flooring, and cabinetry.

Conclusion

In conclusion, HDF wood is a popular choice in the construction and furniture industry. With its high density and strength, HDF wood offers exceptional durability and stability for various applications. Whether it’s for flooring, cabinetry, or shelving, HDF wood provides a reliable and long-lasting solution.

Furthermore, HDF wood is also known for its eco-friendliness and cost-effectiveness. Its manufacturing process involves using recycled wood fibers, making it a sustainable and environmentally conscious choice. Additionally, HDF wood is more affordable compared to solid wood, making it a budget-friendly option for both residential and commercial projects.

In summary, HDF wood combines strength, durability, and affordability, making it an ideal choice for various construction and furniture projects. Its versatility and eco-friendly qualities make it a smart choice for those looking for reliable and sustainable materials.