If you’re looking to add precision and intricate designs to your woodworking projects, laser cutting is a technique you can’t overlook. Laser cutting wood involves using a high-powered laser to cut through the material with incredible precision, leaving clean edges and intricate details. Whether you’re a hobbyist or a professional woodworker, laser cutting can take your craftsmanship to a whole new level.

With laser cutting, you can create intricate patterns, engrave designs, and even cut complex shapes with ease. The laser beam melts or vaporizes the wood as it moves along the predetermined cutting path, resulting in smooth and precise cuts. This method offers a high level of accuracy, allowing you to create custom designs and bring your creative visions to life.

One of the major advantages of laser cutting wood is its versatility. You can work with various types of wood, including plywood, hardwood, MDF, and even veneer. The laser cutter can handle different thicknesses and sizes of wood, making it suitable for a wide range of woodworking projects.

In addition to its accuracy and versatility, laser cutting wood offers other benefits such as speed and efficiency. The laser beam cuts through the wood quickly, reducing production time significantly. Moreover, the laser cuts with precision, minimizing waste and ensuring you get the most out of your materials.

To laser cut wood, you’ll need a laser cutter machine specifically designed for woodworking. These machines are equipped with a high-powered laser and

Safety Precautions for Laser Cutting Wood

When it comes to laser cutting wood, safety should always be the top priority. Laser cutting is a highly precise and efficient method of cutting and engraving wood, but if not done correctly, it can pose serious risks. In this section, we will discuss some important safety precautions that should be followed when laser cutting wood.

1. Use Appropriate Personal Protective Equipment

Prior to starting any laser cutting operation, it is essential to wear the appropriate personal protective equipment (PPE). This includes safety glasses that are specifically designed to block the wavelength of the laser being used. The PPE should also include gloves to protect hands from potential burns, as well as a lab coat or apron to protect clothing from sparks or debris.

2. Ensure Proper Ventilation

Proper ventilation is crucial when laser cutting wood. The process can produce harmful fumes and smoke, especially when cutting certain types of wood. It is important to have a well-ventilated area or to use an exhaust system to remove the fumes and smoke from the workspace. This will help to prevent inhalation of potentially toxic substances.

3. Secure Workpieces Properly

Before starting the laser cutting process, it is important to securely fasten the workpiece to prevent any movement or shifting during operation. This can be done using clamps or other appropriate methods. A stable workpiece ensures precise and accurate cuts and reduces the risk of accidents or injuries.

4. Set Correct Laser Parameters

Setting the correct laser parameters is essential for safe and accurate laser cutting. This includes selecting the appropriate power level, speed, and focus for the specific type and thickness of wood being cut. Using incorrect parameters can lead to incomplete or uneven cuts, which may increase the risk of accidents. Always consult the manufacturer’s guidelines and recommendations for the specific laser cutting machine being used.

5. Maintain a Clean Work Area

A clean work area is important for safety during laser cutting. Remove any combustible materials or clutter from the vicinity of the laser cutting machine to minimize the risk of fire. Regularly clean the laser cutting machine and surrounding area to remove wood chips, dust, or debris that may interfere with the cutting process.

6. Monitor the Cutting Process

It is crucial to closely monitor the laser cutting process throughout the operation. Never leave the machine unattended while in use, especially if there is a risk of fire. Keep a close eye on the machine and the wood being cut to ensure that everything is progressing smoothly. Be prepared to stop the process immediately if any abnormalities or hazards arise.

7. Have a Fire Safety Plan

Despite taking all safety precautions, there is always a risk of fire when laser cutting wood. It is important to have a fire safety plan in place, including the availability of fire extinguishers and knowledge of how to use them. Additionally, make sure there are no flammable materials nearby that could contribute to a fire.

8. Properly Dispose of Waste Materials

After completing a laser cutting operation, it is essential to properly dispose of any waste materials. This may include wood chips, scraps, or residue. Dispose of these materials in accordance with local regulations and guidelines to prevent any environmental or safety hazards.

In summary, laser cutting wood can be a safe and effective method when proper safety precautions are followed. Always wear the appropriate personal protective equipment, ensure proper ventilation, securely fasten workpieces, set correct laser parameters, maintain a clean work area, monitor the cutting process, have a fire safety plan, and dispose of waste materials properly. By following these safety measures, you can ensure a safe and successful laser cutting experience.

Tips for Achieving Clean and Precise Laser Cuts on Wood

Woodworking has been taken to a whole new level with the introduction of laser cutting technology. Laser cutting allows for intricate designs and precise cuts on various materials, including wood. However, achieving clean and precise laser cuts on wood requires careful consideration and attention to detail. In this section, we will discuss some valuable tips that can help you achieve the best results when laser cutting wood.

1. Choose the Right Type of Wood

The type of wood you choose for laser cutting can greatly impact the quality of the final result. Different woods have different densities and characteristics, which can affect how the laser interacts with the material. For clean and precise cuts, it is recommended to use woods with consistent density, minimal knots, and a smooth surface. Some popular choices include plywood, MDF (Medium Density Fiberboard), and hardwood.

2. Prepare the Wood Surface

Before starting the laser cutting process, it is essential to prepare the wood surface properly. Ensure that the wood is clean, free from dust, and any loose particles. Dust and debris on the surface can interfere with the laser beam and lead to uneven cuts. It is also advisable to apply masking tape on the wood surface to prevent scorching or burning. The tape acts as a protective layer and can be easily removed after the cutting is complete.

3. Optimize the Laser Settings

The laser settings play a crucial role in achieving clean and precise cuts on wood. Adjusting the power, speed, and frequency of the laser beam can help you achieve the desired results. It is recommended to start with lower power and speed settings and gradually increase them until you achieve the desired cut quality. Additionally, performing test cuts on a scrap piece of wood can help you fine-tune the settings before working on the final piece.

4. Use High-Quality Optics

The quality of the laser optics can significantly affect the precision of the cuts. It is essential to regularly clean and maintain the optics to ensure optimal performance. Dust, debris, or scratches on the lenses can distort the laser beam and lead to inaccurate cuts. Additionally, using high-quality lenses and mirrors can help minimize the loss of power and improve the overall cutting quality.

5. Consider the Thickness of the Wood

The thickness of the wood can influence the laser cutting process. Different laser systems have limitations on the maximum thickness of wood they can cut effectively. It is important to check the specifications of your laser cutting machine and adjust the settings accordingly. If you need to cut thicker wood, consider using multiple passes or investing in a machine with higher wattage.

6. Apply Proper Ventilation and Extraction

During the laser cutting process, a significant amount of smoke and fumes can be generated. Proper ventilation and extraction systems are essential to maintain a clean and safe working environment. Ensure that your workspace has adequate ventilation to remove the smoke and fumes efficiently. A well-maintained extraction system will help prevent scorching or discoloration of the wood and ensure the laser cuts remain clean and precise.

7. Post-Processing and Finishing

After the laser cutting is complete, some post-processing may be required to achieve the desired finish. Depending on the wood type and design, you may need to sand the edges to remove any burn marks or roughness. Applying a finish such as varnish or paint can further enhance the visual appeal and protect the wood from moisture and wear.

In summary, achieving clean and precise laser cuts on wood requires careful wood selection, proper surface preparation, optimization of laser settings, use of high-quality optics, consideration of wood thickness, implementation of proper ventilation and extraction, and post-processing and finishing. By following these tips, you can enhance the quality of your laser-cut wood projects and create stunning, intricate designs.

Creative Ideas for Laser Cut Wood Projects

Woodworking has been a popular hobby for centuries, and with the advent of laser cutting technology, it has become even more exciting and versatile. Laser cut wood projects allow for intricate designs, precise cuts, and endless possibilities. Whether you are a beginner or an experienced woodworker, here are some creative ideas to inspire your next laser cut wood project:

1. Custom Engraved Signs

One of the most popular applications of laser cutting in woodworking is creating custom engraved signs. Whether it’s a house number, a welcome sign, or a personalized nameplate, laser cutting allows for precise engraving and intricate designs. You can experiment with different fonts, patterns, and shapes to create unique and eye-catching signs.

2. Intricate Jewelry

Laser cut wood is an excellent material for creating unique and intricate jewelry pieces. From earrings and necklaces to bracelets and rings, the possibilities are endless. You can experiment with different types of wood, combine it with other materials like metal or acrylic, and create stunning jewelry designs that are sure to stand out.

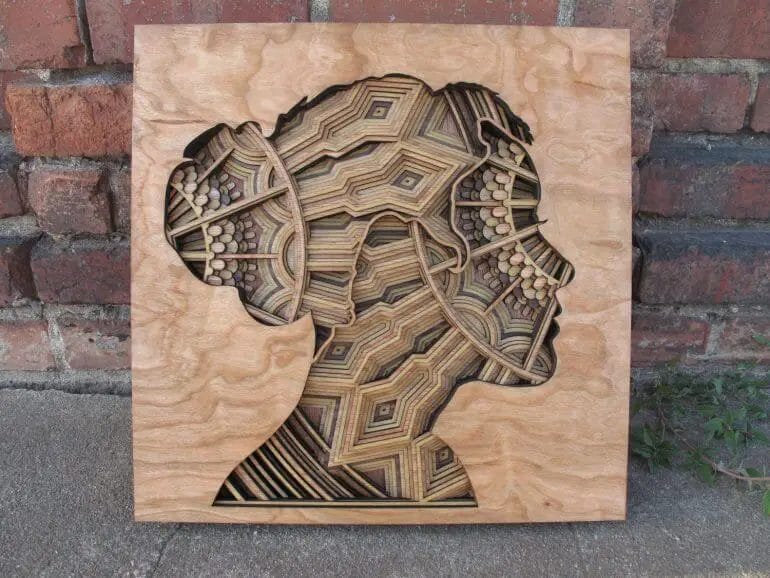

3. Decorative Wall Art

Laser cut wood is perfect for creating decorative wall art pieces that can add a touch of personality to any room. Whether it’s a intricate wooden mandala, a nature-inspired design, or a geometric pattern, laser cutting allows you to create detailed and eye-catching wall art that can be a focal point in any space.

4. Puzzle Toys

Laser cut wooden puzzles are not only great for entertainment but also for cognitive development. You can create intricate and challenging puzzles that require problem-solving skills and enhance spatial awareness. From jigsaw puzzles to 3D puzzles, you can design and create unique and engaging toys for both kids and adults.

5. Home Decor Accents

Laser cut wood can be used to create a wide range of home decor accents that add a touch of elegance and uniqueness to any space. From lampshades and candle holders to coasters and key holders, you can experiment with different designs and patterns to create functional and visually appealing home decor pieces.

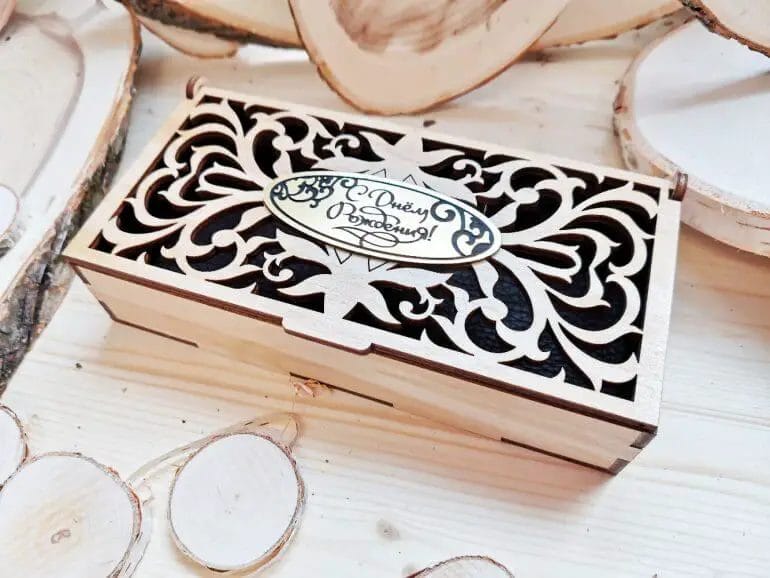

6. Customized Gifts

With laser cutting, you can create personalized and customized gifts that are truly one-of-a-kind. From photo frames and keepsake boxes to cutting boards and wine racks, you can add personal touches like names, dates, or special messages to make the gift extra special.

7. Architectural Models

Laser cut wood is perfect for creating detailed and accurate architectural models. Whether it’s a miniature replica of a famous landmark or a custom-designed building, laser cutting allows you to create precise and intricate models that showcase your attention to detail.

8. Laser Cut Furniture

If you’re feeling ambitious, you can even create laser cut wood furniture pieces. From chairs and tables to shelves and bookcases, laser cutting allows for precise cuts and intricate designs that can take your furniture to the next level.

These are just a few creative ideas to get you started on your laser cut wood projects. With the right tools, materials, and imagination, the possibilities are endless. So dive into the world of laser cutting and let your creativity soar!

Troubleshooting Common Issues in Laser Cutting Wood

Wood laser cutting is a popular technique used in various industries, such as woodworking, crafting, and manufacturing. However, like any other process, it can encounter several issues that can affect the quality of the final product. In this article, we will discuss some of the common problems that arise during laser cutting wood and provide troubleshooting tips to overcome them.

1. Burn Marks on the Edges

One of the most common issues in laser cutting wood is the presence of burn marks on the edges of the cut. These burn marks can be caused by various factors, including excessive laser power or a slow cutting speed.

To troubleshoot this problem, you can try reducing the laser power or increasing the cutting speed. Additionally, using a lower frequency may also help in minimizing burn marks. It is important to find the right balance between laser power, cutting speed, and frequency to achieve clean cuts without burn marks.

2. Charring on the Surface

Charring refers to the black discoloration or scorching of the wood surface during laser cutting. This issue can occur when the laser dwell time is too long or when the wood material is of poor quality.

To avoid charring, you can try reducing the dwell time by adjusting the laser settings. Using higher-quality wood with a lower resin content can also help in minimizing charring. Additionally, applying masking tape or using a cutting bed with a sacrificial layer can protect the surface of the wood and prevent charring.

3. Material Ignition

Wood is a combustible material, and laser cutting generates heat, which can lead to material ignition if not properly controlled. Material ignition is a serious safety hazard and can cause damage to the equipment or even lead to a fire.

To prevent material ignition, it is essential to have a properly calibrated laser machine and ensure that the cutting parameters are within the safe range. Always monitor the cutting process and have fire extinguishing equipment nearby as a precautionary measure. Proper ventilation and removal of any flammable materials from the work area are also important to reduce the risk of material ignition.

4. Inconsistent Cutting Depth

Inconsistent cutting depth can result in uneven edges and affect the overall quality of the cut. This issue can occur due to a misalignment of the laser beam, an uneven surface of the wood, or improper focusing of the laser.

To address this problem, you can check and calibrate the laser alignment regularly. Ensure that the wood surface is flat and level before starting the cutting process. Properly focus the laser beam on the wood surface to achieve consistent cutting depth. If the issue persists, it may be necessary to consult the manufacturer or a professional technician for further assistance.

5. Kerf Width Variation

Kerf width refers to the width of the cut made by the laser. In some cases, there may be variations in the kerf width, which can affect the accuracy and fit of the parts being cut.

To overcome this issue, you can try adjusting the cutting speed or laser power to achieve a more consistent kerf width. Using a higher-quality laser lens and ensuring proper maintenance of the laser machine can also help in minimizing kerf width variation.

In summary, laser cutting wood can encounter various issues, including burn marks, charring, material ignition, inconsistent cutting depth, and kerf width variation. By troubleshooting these common problems and implementing the appropriate solutions, you can achieve high-quality cuts and improve the overall efficiency of the laser cutting process.

FAQs

Q: How do I laser cut wood?

To laser cut wood, you first need to create a design file using design software. Then, set up the laser cutter with the appropriate settings for wood, such as power and speed. Place the wood material on the laser bed, secure it, and start the cutting process. Ensure proper ventilation and safety precautions while operating the laser cutter.

Q: What types of wood can be laser cut?

Various types of wood can be laser cut, including plywood, MDF, birch, maple, cherry, and walnut. However, the cutting quality and compatibility may vary depending on the specific type of wood. Experimenting with different settings and conducting tests can help determine the best results for a particular wood type.

Q: Can I laser engrave wood instead of cutting it?

Yes, laser engraving is a common technique used on wood. Instead of cutting through the wood, the laser focuses on burning the surface, creating intricate designs, patterns, or text. Laser engraving provides a precise and detailed finish on wood, allowing for customization and personalization.

Conclusion

In conclusion, laser cutting wood is a versatile and efficient process that offers a wide range of possibilities for various applications. The precision and accuracy of laser cutting allow for intricate designs and detailed cuts on different types of wood. Whether you are a DIY enthusiast or a professional woodworker, laser cutting can help you bring your creative ideas to life.

By using a laser cutting machine, you can easily achieve smooth edges, precise cuts, and intricate patterns, making it an ideal choice for woodworking projects. Additionally, laser cutting is a time-efficient method that can save you valuable production time and resources.

With the ability to cut and engrave wood with precision, laser cutting opens up new opportunities for customization and personalization in the woodworking industry. From furniture design to decorations and prototypes, laser cutting is a valuable tool for any woodworking enthusiast or professional.