Wood is a heterogeneous material that consists of various components, such as cellulose, hemicellulose, lignin, and extractives. These components are arranged in a complex and irregular manner, resulting in the heterogeneous nature of wood. Each part of the wood has different properties and characteristics, making it a versatile material for construction, furniture-making, and other applications. Despite its heterogeneity, wood still offers unique and desirable qualities, such as strength, durability, and natural beauty.

Examining the Homogeneity of Wood: An In-depth Analysis

Wood is one of the most versatile and widely used materials in various industries. From construction to furniture making, its durability and aesthetic appeal make it an ideal choice for many applications. However, not all wood is the same. The homogeneity of wood, or the degree to which its properties remain consistent throughout, plays a crucial role in determining its quality and suitability for specific purposes.

Wood is composed of a complex structure comprising various cellular components such as cellulose, hemicellulose, and lignin. These components are responsible for the mechanical and physical properties of wood. Examining the homogeneity of wood involves analyzing these components and their distribution within the material.

Methods for Examining Wood Homogeneity

There are several methods available for examining the homogeneity of wood. These methods range from simple visual inspection to advanced analytical techniques. Let’s take a closer look at some of these methods:

- Visual Inspection: Visual inspection involves observing the wood’s surface for any visible irregularities or variations in color, texture, or grain pattern. While this method provides a quick assessment, it may not provide a comprehensive analysis of wood homogeneity.

- Macroscopic Analysis: Macroscopic analysis involves examining wood samples at a larger scale, typically with the naked eye or a low-powered magnifying glass. This method allows for the identification of macro-level variations in wood structure, such as knots, density differences, or growth ring patterns.

- Microscopic Analysis: Microscopic analysis is a more detailed approach that involves using a microscope to examine thin wood sections. This allows for a closer examination of cellular structures and their arrangement within the wood. Microscopic analysis can reveal fine details that are not visible to the naked eye.

- Chemical Analysis: Chemical analysis involves the use of various chemical treatments and tests to assess the composition and properties of wood. These tests can provide insights into the distribution of cellulose, hemicellulose, and lignin within the wood structure.

- Advanced Imaging Techniques: Advanced imaging techniques, such as scanning electron microscopy (SEM) and X-ray imaging, provide highly detailed visualizations of wood structures at a microscopic level. These techniques allow for the analysis of wood homogeneity with exceptional precision.

- Mechanical Testing: Mechanical testing involves subjecting wood samples to various stress and load conditions to evaluate their mechanical properties. This can help identify any variations in strength, stiffness, or elasticity across the wood material.

Importance of Wood Homogeneity

The homogeneity of wood is of utmost importance in several applications. Here are a few reasons why wood homogeneity matters:

- Structural Integrity: In construction, wood with consistent properties throughout ensures the structural integrity of buildings and other wooden structures. Any variations in strength or density can compromise the overall stability.

- Furniture Quality: In furniture making, the homogeneity of wood contributes to the overall quality and durability of the finished product. Consistent properties allow for better joinery and prevent the formation of weak points.

- Manufacturing Efficiency: In industries that rely on wood as a raw material, homogeneity plays a vital role in ensuring efficient manufacturing processes. Consistent properties facilitate accurate machining, cutting, and shaping of wood components.

- Product Performance: Wood homogeneity directly affects the performance of wood-based products such as flooring, decking, and wooden instruments. Evenness and consistency in properties contribute to enhanced durability and longevity.

In summary, examining the homogeneity of wood is crucial for understanding its properties and determining its suitability for various applications. Different methods, ranging from visual inspection to advanced imaging techniques, can be employed to assess wood homogeneity. By ensuring the use of homogeneous wood, industries can achieve better structural integrity, product quality, manufacturing efficiency, and overall customer satisfaction.

Homogeneous vs Heterogeneous Wood: Key Differences Explored

Wood is one of the most widely used materials in various industries, from construction to furniture making. It offers durability, versatility, and a beautiful natural look. However, not all wood is created equal. When it comes to wood, there are two main categories: homogeneous wood and heterogeneous wood. Understanding the differences between these two types of wood is essential for making informed decisions in woodworking projects. In this section, we will explore the key differences between homogeneous wood and heterogeneous wood.

Homogeneous Wood

Homogeneous wood, also known as solid wood, refers to wood that has a consistent composition throughout. It is derived from a single piece of timber or log, making it structurally uniform. The grain pattern, color, and texture are consistent from the core to the outer surface of the wood. Common examples of homogeneous wood include oak, maple, cherry, and walnut.

One of the main advantages of homogeneous wood is its strength and durability. It is solid and less susceptible to warping or splitting. Additionally, homogeneous wood can be easily refinished and repaired, allowing for a longer lifespan. It also offers better acoustic properties compared to other types of wood.

However, there are some limitations to using homogeneous wood. It is more expensive compared to composite or engineered wood due to its natural and premium characteristics. Homogeneous wood is also prone to expansion and contraction with changes in humidity and temperature, requiring proper maintenance to prevent damage.

Heterogeneous Wood

Heterogeneous wood, also known as engineered wood or composite wood, is made by combining multiple layers or pieces of wood with adhesive. Unlike homogeneous wood, heterogeneous wood is not derived from a single piece of timber. It is designed to have specific characteristics and properties that enhance its performance.

There are various types of heterogeneous wood, such as plywood, particleboard, and fiberboard. Each type has its own composition and manufacturing process, resulting in different properties. For example, plywood is made by gluing multiple layers of thin wood veneers together, creating a strong and stable material.

Heterogeneous wood offers several advantages over homogeneous wood. It is more cost-effective and readily available, making it a popular choice in construction and furniture industries. It is also more resistant to moisture, making it less prone to warping or swelling. Heterogeneous wood can be designed to have specific properties, such as fire resistance or improved strength, by altering the composition and manufacturing process.

However, heterogeneous wood also has some limitations. It may not have the same natural beauty and character as homogeneous wood due to the use of multiple layers or pieces. It is also less durable and may require more maintenance compared to homogeneous wood.

In summary, homogeneous wood and heterogeneous wood are two distinct categories of wood with their own set of characteristics and properties. Homogeneous wood offers strength, durability, and natural beauty but comes at a higher cost. Heterogeneous wood, on the other hand, is more cost-effective, versatile, and resistant to moisture but may lack the same aesthetic appeal. Understanding the differences between these two types of wood will help in choosing the right material for specific woodworking projects.

Identifying Homogeneous and Heterogeneous Wood Structures

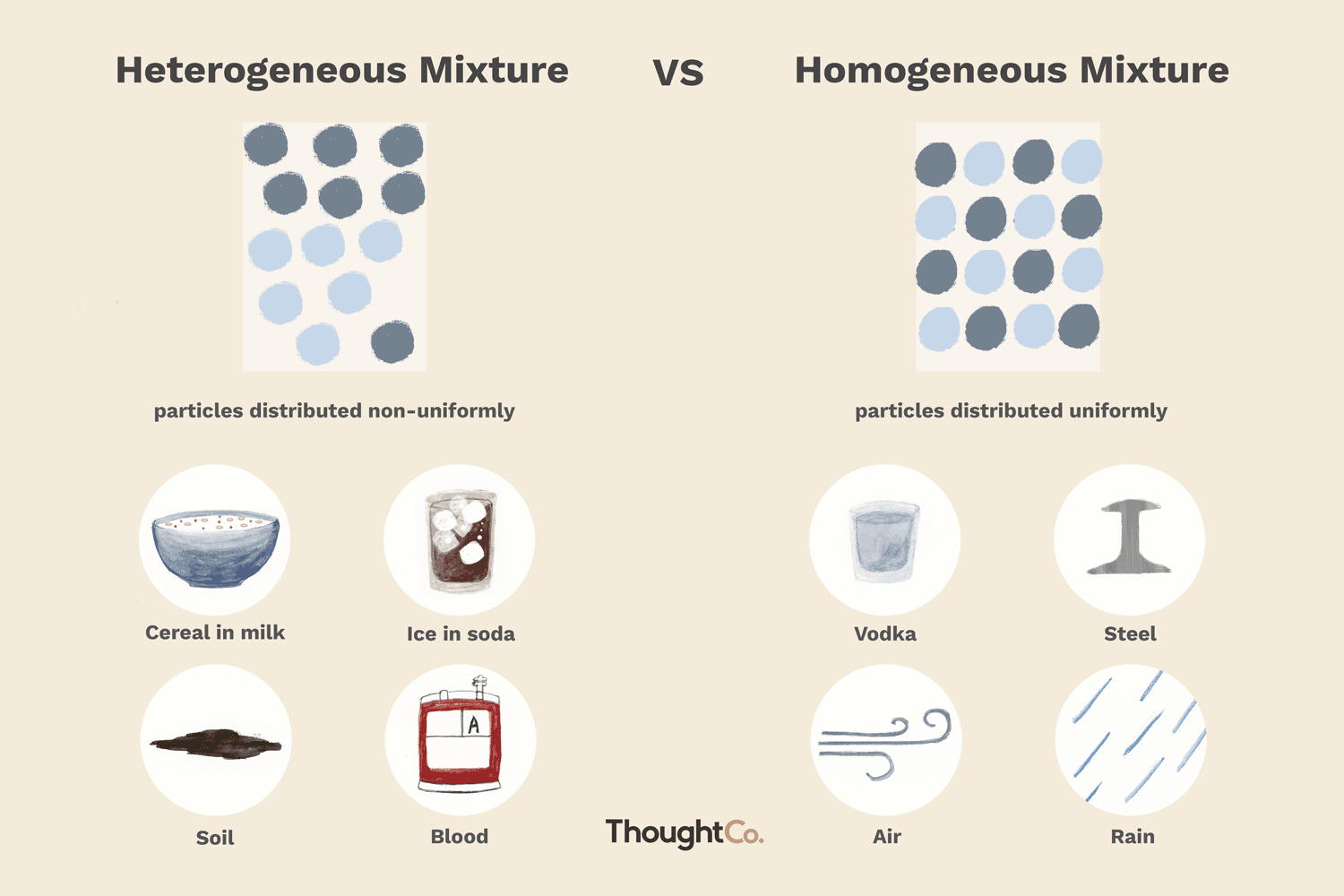

Wood is a versatile and widely used material that comes in various forms and structures. One key aspect of wood is its internal structure, which can be categorized as either homogeneous or heterogeneous. In this section, we will explore what defines these two types of wood structures and methods for identifying them.

Homogeneous Wood Structures

Homogeneous wood structures, also known as uniform wood structures, refer to wood where the cell arrangement and composition are relatively consistent throughout the material. In other words, the cells in homogeneous wood have similar sizes, shapes, and arrangements. This uniformity makes it easier to work with and provides more predictable mechanical properties.

One common example of homogeneous wood is softwood, such as pine or spruce. Softwood typically has long, straight fibers arranged in parallel lines. The cells have thin walls and are mostly made up of cellulose, which gives the wood its strength. Because of the consistent composition and arrangement, softwood is often used in construction, furniture, and paper production.

Identifying homogeneous wood structures can be done through visual inspection and microscopic analysis. By examining the wood’s surface and cross-section, you can observe the uniform texture and arrangement of cells. Additionally, using a microscope can reveal the presence of consistent cell sizes and shapes.

Heterogeneous Wood Structures

Heterogeneous wood structures, also known as non-uniform wood structures, refer to wood where the cell arrangement and composition vary throughout the material. This means that the cells in heterogeneous wood can have different sizes, shapes, and arrangements, creating a more complex and diverse structure.

One common example of heterogeneous wood is hardwood, such as oak or mahogany. Hardwood typically has shorter fibers with irregular shapes and arrangements. The cells often have thicker walls and contain various compounds, such as lignin and hemicellulose, in addition to cellulose. This complex composition gives hardwood its durability and distinctive grain patterns.

Identifying heterogeneous wood structures requires a more detailed examination. Visual inspection can reveal the presence of uneven texture and variations in color and grain patterns. Microscopic analysis can further confirm the presence of different cell sizes, shapes, and arrangements.

Summary

Wood structures can be categorized as either homogeneous or heterogeneous. Homogeneous wood structures have a consistent cell arrangement and composition, making them predictable and easier to work with. Softwood is a common example of homogeneous wood. Heterogeneous wood structures, on the other hand, have varying cell arrangements and compositions, creating a more complex structure. Hardwood is a common example of heterogeneous wood.

Identifying wood structures involves visual inspection and microscopic analysis. For homogeneous wood, the presence of uniform texture, cell arrangement, and consistent cell sizes can indicate its structure. For heterogeneous wood, variations in texture, color, and grain patterns, as well as the presence of different cell sizes and shapes, can indicate its structure.

The Impact of Wood Homogeneity on its Strength and Durability

Wood is a versatile and widely used material, valued for its strength, durability, and aesthetic appeal. However, not all wood is created equal. One important factor that significantly affects the strength and durability of wood is its homogeneity. In this section, we will explore the impact of wood homogeneity on its strength and durability.

Definition of Wood Homogeneity

Wood homogeneity refers to the uniformity of the wood’s physical and structural properties. In other words, it is the degree to which the wood exhibits consistent characteristics throughout its structure. Homogeneous wood has consistent density, moisture content, cell structure, and fiber alignment, while heterogeneous wood may have variations in these properties.

Strength and Homogeneity

The homogeneity of wood directly affects its strength. Homogeneous wood tends to have higher strength properties compared to heterogeneous wood. This is because the consistency in density, moisture content, and fiber alignment allows for more efficient load transfer and resistance to external forces.

When wood is subjected to stress, the load is distributed evenly across homogeneous wood fibers, resulting in better load-bearing capacity. In contrast, wood with variations in density or fiber alignment may have weak areas that are more prone to failure under stress.

Durability and Homogeneity

Wood homogeneity also plays a significant role in the durability of the material. Homogeneous wood is less susceptible to decay, deterioration, and insect infestation compared to heterogeneous wood.

A consistent cell structure and fiber alignment in homogeneous wood impede the entry of moisture and pests, reducing the likelihood of damage. In contrast, variations in density, moisture content, and cell structure in heterogeneous wood create pathways for moisture absorption and pest infiltration, increasing the risk of decay and infestation.

Factors Affecting Wood Homogeneity

Several factors can influence the homogeneity of wood. These include the species of wood, growth conditions, harvesting methods, and processing techniques.

1. Species of Wood: Different tree species have varying levels of natural homogeneity. Some species are naturally more uniform in their characteristics, while others exhibit greater variations.

2. Growth Conditions: The environmental conditions in which the tree grows can impact the homogeneity of the wood. Factors such as soil type, climate, and exposure to pests or diseases can affect the wood’s properties.

3. Harvesting Methods: The way in which the tree is harvested and processed can also influence wood homogeneity. Factors such as logging practices, drying methods, and sawing techniques can introduce variations in the wood’s properties.

4. Processing Techniques: The manufacturing processes used to convert raw wood into finished products can affect homogeneity. Processes such as laminating, veneering, and heat treatment can enhance or alter the wood’s properties.

Importance of Wood Homogeneity in Applications

The impact of wood homogeneity on strength and durability has significant implications for its various applications.

1. Construction: In construction, homogeneous wood is preferred for structural elements such as beams, columns, and joists, as it provides greater load-bearing capacity and structural stability.

2. Furniture and Cabinetry: Homogeneous wood is desirable for furniture and cabinetry to ensure durability and resistance to wear and tear. It also allows for easier machining and finishing processes.

3. Flooring and Decking: Homogeneous wood is essential for flooring and decking materials to withstand foot traffic, moisture, and external exposure. It ensures dimensional stability and prevents warping or cracking.

4. Musical Instruments: Homogeneous wood is sought after in the construction of musical instruments due to its consistent acoustic properties, which contribute to better sound quality and resonance.

In summary, wood homogeneity significantly impacts its strength and durability. Homogeneous wood exhibits consistent characteristics throughout its structure, resulting in higher strength properties and improved resistance to decay and infestation. Factors such as species, growth conditions, harvesting methods, and processing techniques influence the homogeneity of wood. Understanding the importance of wood homogeneity allows for informed decisions in selecting and utilizing wood materials for various applications.

FAQs

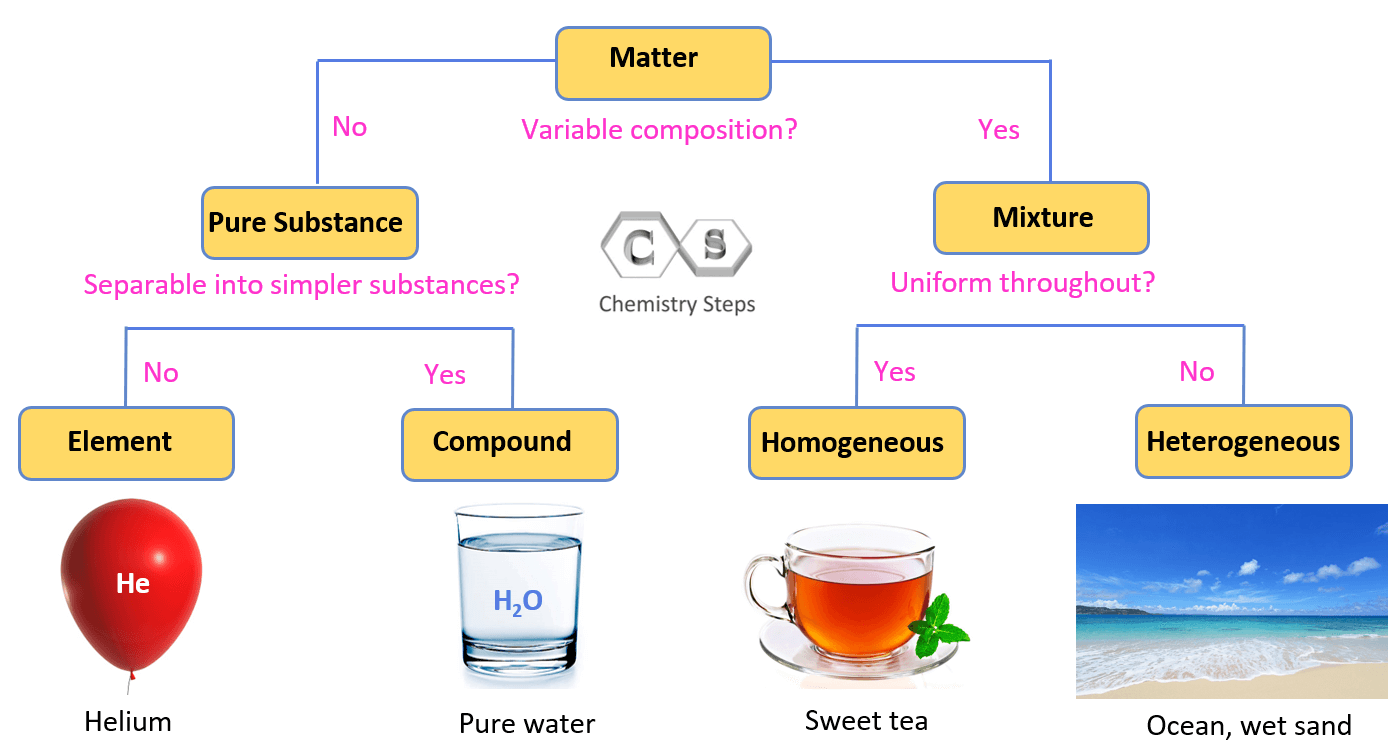

1. Is wood homogeneous or heterogeneous?

Wood is considered a heterogeneous material. It consists of various components, such as cellulose fibers, lignin, and extractives, which have different properties and are not evenly distributed throughout the material.

Conclusion:

In conclusion, the nature of wood can be considered both homogeneous and heterogeneous. Wood is predominantly composed of cellulose and lignin, which give it a relatively uniform appearance and texture, suggesting homogeneity. However, when examined at a microscopic level, wood reveals complex structures consisting of various cell types, such as vessels, fibers, and parenchyma cells, making it heterogeneous. This combination of uniformity and diversity gives wood its unique characteristics and makes it a versatile material for a wide range of applications, including construction, furniture, and crafts.