How Does Powder Coating Enhance the Durability of Wood?

Wood has been a popular material for various applications due to its natural beauty and versatility. However, it is susceptible to damage from external elements such as moisture, UV rays, and pests. To enhance its durability, powder coating has emerged as an effective solution.

Powder coating is a dry finishing process where a fine powder is electrostatically sprayed onto the wooden surface. The powder particles adhere to the surface and then undergo a curing process to create a hard and protective coating. This coating acts as a shield, providing several benefits that enhance the longevity and resilience of wood.

1. Protection against Moisture

Moisture is one of the primary factors that contribute to the deterioration of wood. It can lead to swelling, warping, rotting, and the growth of mold or mildew. Powder coating forms a waterproof barrier on the surface, preventing moisture from seeping into the wood. This effectively safeguards the wood from potential damage caused by prolonged exposure to humidity, rain, or other water sources.

2. UV Resistance

Exposure to sunlight can cause wood to fade, discolor, or develop cracks over time. UV rays can also break down the lignin in wood, which is responsible for its strength and structural integrity. Powder coating contains pigments and additives that offer excellent UV resistance, protecting the wood from fading and maintaining its original appearance for a longer time. Additionally, it acts as a shield against the harmful effects of UV rays, reducing the risk of structural damage.

3. Enhanced Durability

Powder coating creates a hard and durable surface on wood, making it more resistant to abrasion, impact, and wear. This added layer of protection helps the wood withstand daily use, reducing the risk of scratches, dents, or other physical damage. The coating also acts as a barrier against chemical substances, preventing stains or discoloration caused by spills or exposure to harsh cleaning agents.

4. Pest and Termite Resistance

Wood is naturally susceptible to pests such as termites, ants, and fungi, which can cause significant structural damage. Powder coating provides an effective deterrent against these pests, making the wood less attractive and accessible to them. The hard and seamless coating acts as a physical barrier, preventing pests from infiltrating the wood and causing harm.

5. Easy Maintenance

One of the advantages of powder coating on wood is its low maintenance requirements. The durable coating resists dirt, dust, and stains, making it easier to clean and maintain the wood’s appearance. Regular cleaning with mild soap and water is usually sufficient to keep the coated wood in excellent condition, eliminating the need for frequent refinishing or repainting.

In summary, powder coating enhances the durability of wood by providing protection against moisture, UV rays, pests, and physical damage. It creates a hard and long-lasting surface that preserves the natural beauty of wood while reducing maintenance efforts. By opting for powder-coated wood, individuals can enjoy the advantages of a resilient and aesthetically pleasing material for various applications.

Step-by-Step Guide to Powder Coating Wood: A DIY Approach

If you’re looking for a durable and long-lasting finish for your wooden furniture or project, powder coating can be a great option. While powder coating is commonly used on metal surfaces, it is also possible to powder coat wood, providing a seamless and protective coating that enhances the beauty of the natural grain. In this section, we will provide you with a step-by-step guide on how to powder coat wood, allowing you to achieve professional results with a DIY approach.

1. Gather Your Materials

Before you begin the powder coating process, make sure you have all the necessary materials at hand. This includes:

- A piece of wood to be coated

- Powder coating gun and compressor

- Masking tape and paper to protect certain areas from coating

- Clean cloths or compressed air for dust removal

- Paint or powder coating powder of your choice

- Baking oven or heat gun for curing the coating

- Protective gloves, goggles, and mask for personal safety

2. Prepare the Wood Surface

The key to a successful powder coating application is proper preparation of the wood surface. Start by sanding the wood to remove any rough spots or imperfections. This will ensure a smooth and even coating. Next, clean the wood surface thoroughly to remove any dust, dirt, or oils that may interfere with adhesion. You can use a clean cloth or compressed air to achieve this.

3. Masking Off Areas

If there are any areas on the wood that you want to keep free from coating, such as hardware or joints, use masking tape and paper to cover and protect them. This step will help you achieve clean lines and prevent any unwanted coating on these areas.

4. Apply the Powder Coat

Now it’s time to apply the powder coat onto the wood surface. Load the powder coating powder into the powder coating gun according to the manufacturer’s instructions. Hold the gun about 6 to 8 inches away from the wood and spray an even layer of powder across the surface. Make sure to cover the entire area you want to coat.

5. Curing the Coating

After applying the powder coating, it needs to be cured to form a hard and durable finish. There are two methods you can use for curing:

- Baking Oven: If you have access to a baking oven, place the coated wood inside and bake it at the temperature and duration specified by the powder coating manufacturer. This will allow the powder to melt and adhere to the wood surface.

- Heat Gun: If you don’t have a baking oven, you can use a heat gun to cure the coating. Hold the heat gun about 2 to 3 inches away from the surface and move it around to evenly distribute the heat. Be cautious not to overheat the wood or the coating.

6. Finishing Touches

Once the coating has cured and cooled, you can remove the masking tape and paper. Inspect the coated wood for any imperfections or unevenness. If necessary, lightly sand the surface and apply another coat of powder for a flawless finish. Finally, use a clean cloth to wipe off any remaining dust or particles.

7. Enjoy Your Powder Coated Wood

Now that your wood is powder coated and fully cured, it is ready to be enjoyed. Whether it’s a piece of furniture, a decorative item, or a DIY project, the powder coating will provide a durable and attractive finish that will stand the test of time.

In summary, powder coating wood is a great way to achieve a professional and long-lasting finish. By following this step-by-step guide, you can confidently take on the DIY approach and transform your wooden pieces into works of art.

Key Differences Between Powder Coating Wood and Other Materials

When it comes to powder coating, it is essential to understand that the process can be applied to various materials, including metals, plastics, and even wood. While the general concept of powder coating remains the same regardless of the material, there are some key differences when it comes to powder coating wood compared to other materials.

1. Surface Preparation

The first notable difference is the surface preparation required for wood compared to other materials. Wood surfaces need to be properly cleaned, sanded, and primed before the powder coating can be applied. This is because wood is a porous material that can absorb moisture, which can affect the adhesion and durability of the coating. In contrast, metals and plastics typically require less preparation as they are non-porous materials.

2. Heat Sensitivity

Another significant difference is the heat sensitivity of wood compared to other materials. When powder coating wood, it is crucial to ensure that the curing temperature does not exceed the wood’s tolerance level. Excessive heat can cause the wood to warp, crack, or burn. In contrast, metals and plastics can withstand higher curing temperatures without any adverse effects. Therefore, careful temperature monitoring is required when powder coating wood.

3. Coating Thickness

The coating thickness is also a key difference between powder coating wood and other materials. Wood generally requires a thinner coating compared to metals and plastics. This is because excessive coating thickness on wood can result in poor adhesion and could lead to cracking or peeling. Metals and plastics can handle thicker coatings without these issues, providing additional protection and durability.

4. Appearance and Texture

When it comes to the final appearance and texture, powder coating wood can offer unique options compared to other materials. While metals and plastics usually have a smooth and glossy finish, wood surfaces can retain a natural and textured look even after the powder coating process. This can be particularly desirable for applications where a more rustic or organic aesthetic is desired.

5. Environmental Considerations

Lastly, it is important to consider the environmental impact when powder coating wood compared to other materials. Wood is a renewable resource, making it a more sustainable option. Additionally, some powder coatings formulated specifically for wood may be more environmentally friendly, containing fewer harmful chemicals compared to coatings for metals and plastics.

In summary, while powder coating can be applied to various materials, including wood, there are some key differences to consider. Proper surface preparation, heat sensitivity, coating thickness, appearance, and environmental considerations all play a role in the powder coating process for different materials. Understanding these differences is crucial to ensure the best results and durability for each specific application.

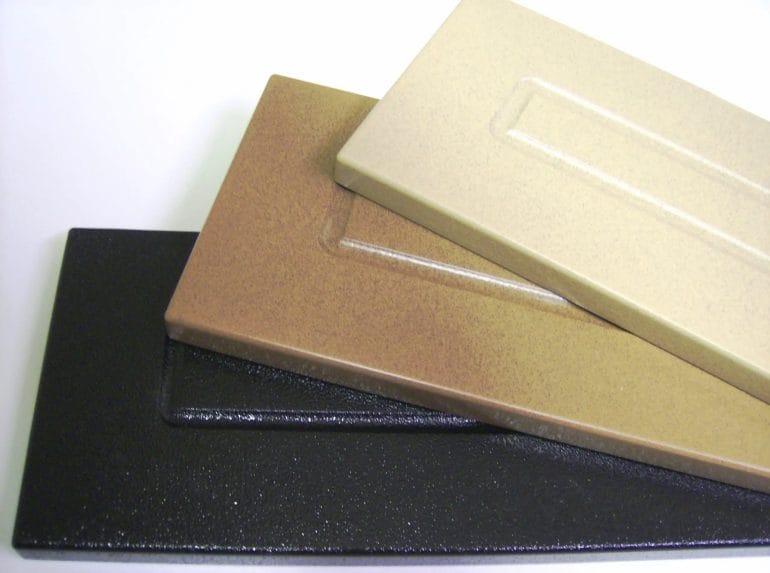

Exploring Color Options and Finishes for Powder Coated Wood

When it comes to powder coated wood, one of the many advantages is the ability to choose from a wide range of colors and finishes. This allows you to customize your wooden surfaces and products to match your desired aesthetic and design preferences. In this section, we will explore the various color options and finishes available for powder coated wood, enabling you to make an informed decision for your project.

1. Standard Color Options

Powder coated wood offers a vast selection of standard color options. These colors are typically available as a result of the manufacturing process and are widely used in various applications. Some popular standard colors include:

- Black

- White

- Gray

- Beige

- Brown

These standard colors are versatile and can complement a wide range of design styles. Whether you prefer a modern, minimalist look or a more traditional appeal, there is a standard color option to meet your requirements.

2. Custom Color Matching

If you have a specific color in mind that is not available in the standard options, powder coated wood also offers custom color matching services. This allows you to choose any color from a color swatch or provide a sample, and the manufacturer will create a powder coat that matches your desired hue precisely.

Custom color matching is especially valuable for projects that require a specific branding color or need to match existing interior or exterior elements. It ensures consistency and cohesiveness in design, making it an excellent choice for architects, interior designers, and businesses with specific color requirements.

3. Specialty Finishes

In addition to a wide range of colors, powder coated wood also offers specialty finishes to enhance the appearance and texture of the coated surfaces. These finishes can add depth, dimension, and visual interest to your wood products. Some popular specialty finishes include:

- Textured finish: Creates a textured surface, adding a tactile element to the wood

- Metallic finish: Mimics the appearance of metal, providing a sleek and modern look

- Gloss or matte finish: Allows you to choose between a high-gloss shine or a subtle matte sheen

- Antique finish: Gives the wood a weathered or aged appearance, perfect for vintage or rustic designs

These specialty finishes can elevate the overall aesthetic of your project, making it stand out and leaving a lasting impression.

4. Durability and Longevity

Aside from the aesthetic benefits, powder coated wood also offers excellent durability and longevity. The powder coating process creates a protective barrier on the wood surface, shielding it from moisture, UV rays, and other environmental factors that can cause damage or fading over time. This means that your chosen color and finish will remain vibrant and intact even after years of use.

Furthermore, powder coated wood is resistant to scratches, chipping, and peeling, ensuring that your surfaces and products maintain their beautiful appearance for an extended period. This durability makes powder coated wood an ideal choice for both indoor and outdoor applications.

5. Applications

With its wide array of color options and finishes, powder coated wood can be used in various applications, including:

- Furniture

- Cabinetry

- Doors and windows

- Architectural elements

- Signage

- Exterior cladding

These are just a few examples of how powder coated wood can transform ordinary surfaces into stunning design elements.

Summary

When it comes to powder coated wood, the options for colors and finishes are virtually limitless. From standard colors to custom color matching, and from textured finishes to glossy or matte surfaces, powder coated wood offers versatility and durability for any design project. Consider your desired aesthetic, functionality, and long-term maintenance when selecting the perfect color and finish for your powder coated wood products or surfaces.

FAQs

Can you powder coat wood?

No, powder coating is not suitable for wood. It requires a high curing temperature and wood cannot withstand that heat without getting damaged. Powder coating is typically used on metals such as steel, aluminum, and iron.

What is the difference between powder coating and painting?

Powder coating is a dry finishing process where a fine powder is electrostatically applied to a surface and then cured under heat to create a durable and protective coating. Painting, on the other hand, involves applying wet paint to a surface and allowing it to dry or cure naturally. Powder coating provides a more durable and eco-friendly finish compared to traditional painting methods.

Can powder coating be applied to any metal?

Generally, powder coating can be applied to a wide range of metals such as steel, aluminum, iron, brass, and many others. However, certain metals with low melting points or high heat sensitivity may not be suitable for powder coating as the curing process requires a high temperature. It is always best to consult with a professional to determine the suitability of a specific metal for powder coating.

Conclusion

In conclusion, while it is technically possible to powder coat wood, it is not a common practice and may not yield the desired results. Powder coating is typically used on metal surfaces due to its durability, resistance to chipping, and aesthetic appeal. Wood, on the other hand, is a porous and organic material that may not provide a suitable surface for the powder coating process. Additionally, the high temperatures involved in the curing process may damage or warp the wood. It is recommended to explore alternative finishes and treatments specifically designed for wood to achieve the best results and preserve its natural beauty.