When it comes to burning wood, the process itself does not seal it. In fact, burning wood can actually have the opposite effect, causing the wood to dry out and crack due to the high temperatures. However, there are certain wood treatments and finishes that can help seal and protect the wood, enhancing its durability and longevity. These treatments, such as varnishes or sealants, create a protective layer that can help prevent moisture and other elements from penetrating the wood, keeping it sealed and protected for years to come.

How Burning Wood Affects the Sealing Process

When it comes to sealing wood, it is important to understand how different factors can affect the process. One such factor is the burning of wood. Burning wood can have a significant impact on the sealing process and it is important to be aware of these effects.

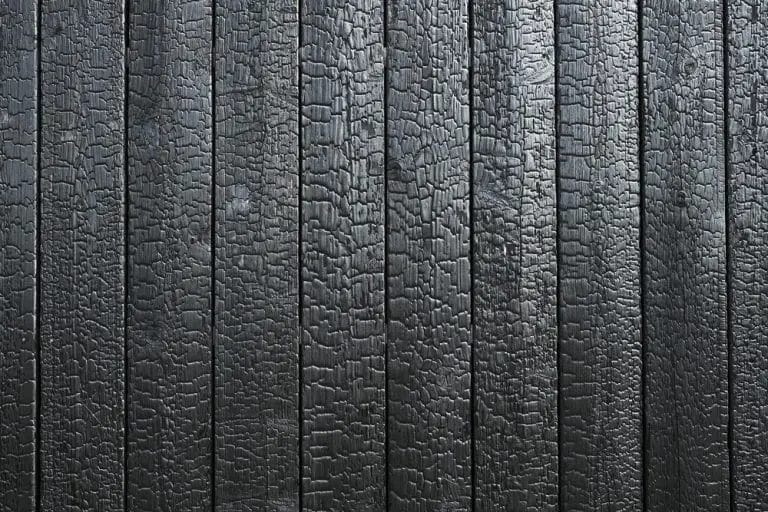

1. Changes in Wood Surface: When wood is burned, it undergoes several physical and chemical changes. The intense heat from burning can cause the wood surface to become charred and brittle. This can result in the formation of cracks, splits, and rough patches on the wood surface. These changes can affect the effectiveness of the sealing process, as the sealant may not be able to properly adhere to the damaged wood surface.

2. Smoke and Soot Residue: Burning wood produces smoke and soot, which can settle on the wood surface. These residues can leave behind a layer of grime and impurities on the wood, making it difficult for the sealant to penetrate and adhere properly. It is important to thoroughly clean the burned wood surface to remove any residue before applying the sealant.

3. Increased Porosity: Burning wood can increase its porosity. The heat from burning can cause the wood fibers to expand, creating gaps and openings in the wood structure. This increased porosity can make the wood more susceptible to moisture absorption and damage. It is important to choose a sealant that is specifically designed for porous wood surfaces to ensure effective protection.

4. Chemical Changes: Burning wood can also result in chemical changes within the wood structure. The combustion process can release volatile organic compounds (VOCs), which can be absorbed by the wood. These VOCs can affect the performance of the sealant and may even cause discoloration or chemical reactions. It is important to choose a sealant that is compatible with burned wood to ensure optimal results.

5. Preparing Burned Wood for Sealing: Before applying a sealant to burned wood, it is crucial to properly prepare the surface. Start by thoroughly cleaning the wood to remove any smoke and soot residue. Sand the surface to smooth out any rough patches or charring. Fill in any cracks or splits with an appropriate wood filler. Once the wood surface is clean and repaired, carefully choose a sealant that is suitable for burned wood.

In summary, burning wood can have various effects on the sealing process. It can cause physical and chemical changes to the wood surface, increase its porosity, and leave behind smoke and soot residues. To ensure effective sealing, it is important to properly prepare the burned wood surface and choose a sealant that is compatible with the specific characteristics of burned wood. By understanding these effects, you can make informed decisions and achieve optimal results in your wood sealing projects.

Factors to Consider When Using Burning Wood for Sealing

Using burning wood for sealing can be an effective and environmentally friendly method. However, there are several factors that need to be considered to ensure safety and achieve optimal results. In this section, we will discuss some important factors to keep in mind when using burning wood for sealing projects.

1. Type of Wood

The type of wood you choose for burning will have a significant impact on the outcome of your sealing project. Different types of wood have different burning properties, such as heat intensity, burn rate, and the amount of smoke produced. Hardwoods like oak and maple are ideal for sealing as they burn slowly and produce long-lasting heat. Softwoods like pine, on the other hand, burn more quickly and may not provide the same level of heat and longevity.

It is important to select the right type of wood for your specific sealing needs. Consider the size of the area you need to seal and choose a wood type that can generate enough heat to effectively seal the surface.

2. Moisture Content

The moisture content of the wood is another crucial factor to consider. Wood that is too wet or has a high moisture content will not burn efficiently, resulting in excessive smoke and incomplete sealing. It is recommended to use wood with a moisture content of less than 20% for optimal burning and sealing results.

Ensure that the wood you use is properly seasoned and dried before using it for sealing. This will help reduce moisture content and improve the quality of the burn.

3. Safety Precautions

When using burning wood for sealing, safety should be your top priority. Make sure to take the necessary precautions to prevent accidents and protect yourself and the surrounding environment.

Here are some safety measures to follow:

- Operate in a well-ventilated area to minimize smoke accumulation.

- Keep a fire extinguisher nearby in case of emergencies.

- Wear protective gear such as gloves and goggles to shield yourself from sparks and heat.

- Never leave the burning wood unattended and ensure that the fire is completely extinguished after use.

4. Proper Application Techniques

To achieve the desired sealing results, it is important to use the burning wood correctly. Here are some tips for proper application:

- Start with a clean and dry surface free from debris and dirt.

- Light the wood and allow it to burn until you have a bed of hot embers.

- Use a brush or applicator to spread the hot embers evenly across the surface.

- Apply multiple layers if necessary for a more durable and long-lasting seal.

Following these application techniques will help ensure an even distribution of the burning wood and enhance the effectiveness of the sealing process.

5. Environmental Impact

While burning wood for sealing can be an eco-friendly option, it is important to consider the environmental impact. Wood smoke contains pollutants and fine particulate matter that can contribute to air pollution. To minimize the impact, choose wood with low smoke emission properties and ensure proper ventilation during the burning process.

Additionally, consider alternative sealing methods that may have a lower environmental impact, such as water-based sealants or environmentally friendly wood treatments.

Summary

Using burning wood for sealing can be a cost-effective and sustainable option. However, it is crucial to consider factors such as the type of wood, moisture content, safety precautions, proper application techniques, and the environmental impact. By taking these factors into account, you can achieve optimal results while ensuring safety and minimizing the impact on the environment.

Alternatives to Burning Wood for Sealing

Wood burning has been a popular method for sealing wood for many years. It involves using open flames to char the surface of the wood, creating a protective layer that helps to prevent rot and decay. However, burning wood can be time-consuming, labor-intensive, and potentially dangerous. Additionally, it can release harmful chemicals into the air, contributing to air pollution. As a result, many people are seeking alternative methods for sealing wood that are safer, more efficient, and environmentally friendly. In this section, we will explore some of the popular alternatives to burning wood for sealing.

1. Wood Sealers and Stains

One of the most common alternatives to burning wood is using wood sealers and stains. These products are specially formulated to penetrate the wood’s surface, creating a protective barrier against moisture, UV rays, and other environmental factors. Wood sealers and stains come in a variety of finishes, ranging from clear to colored options, allowing you to enhance the natural beauty of the wood while providing long-lasting protection. They are easy to apply and can be brushed, rolled, or sprayed onto the wood surface.

When choosing a wood sealer or stain, it is important to select a product that is specifically designed for the type of wood you are working with. Different wood species have different characteristics and absorb sealers differently. It is also crucial to follow the manufacturer’s instructions for application and reapplication to ensure optimal results.

2. Polyurethane Sealants

Polyurethane sealants are another popular alternative to burning wood for sealing. These sealants provide a durable, waterproof coating that protects the wood from moisture, UV rays, and other external elements. Polyurethane sealants come in both water-based and oil-based formulations, offering different levels of durability and finish options.

Water-based polyurethane sealants are easier to clean up and have lower VOC (Volatile Organic Compound) emissions compared to their oil-based counterparts. They also dry faster, allowing for quicker project completion. On the other hand, oil-based polyurethane sealants tend to create a richer, more amber-toned finish and provide superior durability. The choice between water-based and oil-based polyurethane sealants depends on personal preference and the specific requirements of the project.

3. Epoxy Resin Coatings

Epoxy resin coatings are a popular choice for sealing wood surfaces that require a high level of protection and durability. These coatings are made by mixing epoxy resin with a hardener, which then cures to form a strong, clear, and glossy finish. Epoxy resin coatings are highly resistant to moisture, chemicals, and UV rays, making them suitable for both indoor and outdoor applications.

The application process for epoxy resin coatings involves mixing the resin and hardener according to the manufacturer’s instructions, then pouring or brushing the mixture onto the wood surface. It is important to work in a well-ventilated area and wear appropriate protective equipment when working with epoxy resin due to its strong odor and potential skin and eye irritation.

4. Natural Oils

Natural oils, such as tung oil and linseed oil, can also be used as alternatives to burning wood for sealing. These oils penetrate the wood’s surface, nourishing and protecting it from within. They provide a low sheen, natural-looking finish and enhance the wood’s natural grain. Natural oils are particularly suitable for interior wood surfaces, such as furniture and cabinetry.

When using natural oils, it is important to apply multiple coats and allow sufficient drying time between each coat. This helps to ensure proper absorption and provides an even, long-lasting finish. Natural oils may require periodic reapplication to maintain their protective properties.

In summary

While burning wood has long been a traditional method for sealing wood, there are several alternatives available that are safer, more efficient, and environmentally friendly. Wood sealers and stains, polyurethane sealants, epoxy resin coatings, and natural oils offer different levels of protection and finishes, allowing you to choose the best option for your specific wood sealing needs. Remember to consider the type of wood, application method, and manufacturer’s instructions when selecting and applying these alternatives. By exploring these alternatives, you can achieve a beautiful, protected wood surface without the need for burning.

Best Practices for using Burnt Wood as a Sealing Method

Using burnt wood as a sealing method can provide a unique and aesthetically pleasing finish to various surfaces. Whether you are working on a woodworking project or looking to enhance the appearance of your interior or exterior spaces, understanding the best practices for using burnt wood can help you achieve the desired results. In this section, we will explore some key considerations and techniques to effectively use burnt wood as a sealing method.

1. Safety Precautions

Prior to starting any burnt wood project, it is essential to prioritize safety. Burning wood can produce harmful fumes, so it is crucial to work in a well-ventilated area or use proper respiratory protection. Additionally, make sure to wear proper protective gear such as goggles, gloves, and a mask to prevent any potential injuries.

2. Wood Selection

The type of wood you choose for your project can significantly impact the final result. Softwoods like pine or cedar are commonly used as they tend to burn evenly and provide a distinct burned grain pattern. Hardwoods such as oak or maple can also be used, but they may require more effort and time to achieve the desired results. It is recommended to select high-quality wood with a smooth surface to ensure a consistent and appealing appearance.

3. Surface Preparation

Before starting the burning process, it is essential to prepare the wood surface properly. Begin by sanding the wood to remove any imperfections or roughness. This will not only create a smooth surface but also help the burnt wood adhere better. Clean the wood surface thoroughly to remove any dust or debris that may affect the burning process.

4. Burning Technique

There are various methods you can use to burn the wood surface, each with its unique effects. One popular technique is to use a propane torch or a handheld butane torch. Hold the torch at a slight angle and move it evenly across the wood surface, allowing the flame to make contact with the wood. This will create a darkened, charred effect. Alternatively, you can use a wood burning tool with different tips to create intricate designs or patterns.

5. Control and Consistency

While burning the wood, it is crucial to maintain control and consistency to achieve the desired appearance. Keep the flame at a consistent distance from the wood surface to ensure even burning. Avoid leaving the flame in one area for too long to prevent excessive charring or damage to the wood. Regularly step back and assess the progress to ensure a uniform and appealing result.

6. Finishing and Sealing

Once the desired burnt effect is achieved, it is essential to finish and seal the wood to protect it and enhance its appearance. Begin by gently sanding the burnt surface to remove any loose ash or debris. Apply a clear protective finish, such as polyurethane or a wood sealant, to seal the wood and provide durability. This will also help preserve the burnt wood effect and prevent fading or deterioration over time.

In summary, using burnt wood as a sealing method can add a unique touch to your woodworking projects or enhance the aesthetics of your living spaces. By following these best practices, including prioritizing safety, selecting the right wood, preparing the surface, employing the appropriate burning technique, maintaining control and consistency, and finishing and sealing the wood, you can achieve stunning results that will impress and endure.

FAQs

Does burning wood seal it?

No, burning wood does not seal it. In fact, burning wood causes it to lose moisture and become more porous. This can actually make the wood more susceptible to moisture damage and decay.

Conclusion

In conclusion, burning wood does not seal it. Instead, it transforms the wood by converting the organic matter into carbon dioxide and water vapor. This process, known as combustion, releases heat and gases, leaving behind the charred remains of the wood. While burning can alter the appearance and composition of wood, it does not create a seal or prevent moisture absorption.

It is important to note that if you are looking to seal wood, there are alternative methods such as using sealants, varnishes, or paint. These options create a protective barrier that helps to prevent moisture penetration and maintain the integrity of the wood over time. So, if sealing is your goal, burning wood is not the right approach and you should explore other suitable options.