Wondering if a piece of wood is pressure treated? Look for these telltale signs. Pressure treated wood is commonly used for outdoor projects like decks and fences due to its durability and resistance to rot and insects. One way to identify pressure treated wood is by its green or brown color, which is a result of the chemical treatment process. Another clue is the presence of small indentations or cut marks on the surface, where the treatment solution may have been absorbed. Lastly, check for a stamp or label indicating that the wood has been pressure treated.

Signs to Look for When Determining if Wood is Pressure Treated

Pressure treated wood is a popular choice for outdoor construction projects due to its durability and resistance to rot and pests. However, it is important to be able to identify pressure treated wood to ensure that you are using the right type of wood for your project. Here are some signs to look for when determining if wood is pressure treated:

1. Greenish or Brownish Hue

One of the most obvious signs of pressure treated wood is its color. Pressure treated wood often has a greenish or brownish hue due to the chemicals used in the treatment process. This coloration is a result of the copper compounds used to protect the wood from decay and insects.

2. Check for Tag or Stamp

Most pressure treated wood will have a tag or stamp that indicates that it has been treated. The tag or stamp may contain information such as the type of wood, the treatment process used, and the certification mark of the treatment agency. Look for these markings to ensure that the wood you are using is pressure treated.

3. Grooves or Incisions

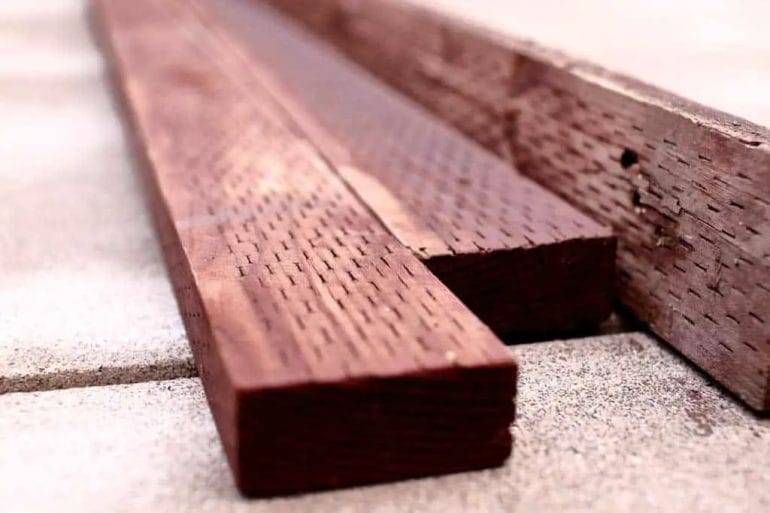

Another sign to look for is the presence of grooves or incisions on the surface of the wood. These grooves are made during the pressure treatment process to allow the chemicals to penetrate the wood more effectively. If you notice these grooves, it is a good indication that the wood has been treated.

4. Smell

Pressure treated wood can have a distinct odor due to the chemicals used in the treatment process. If you notice a strong, chemical-like smell when working with the wood, it is likely that it is pressure treated. This smell may dissipate over time, but it can be a helpful indicator during the initial assessment.

5. Resistance to Moisture

Pressure treated wood is highly resistant to moisture, which is one of the reasons it is commonly used for outdoor applications. If you notice that the wood repels water or does not absorb moisture easily, it is likely that it has been pressure treated. This resistance to moisture is a result of the chemicals infused into the wood during the treatment process.

6. Use of Gloves and Safety Precautions

When working with wood that you suspect is pressure treated, it is important to take appropriate safety precautions. Always wear gloves and a mask to protect yourself from any potential health risks associated with the chemicals used in the treatment process. Following proper safety guidelines is crucial to ensure your well-being.

In summary, identifying pressure treated wood can be done by observing its color, checking for tags or stamps, looking for grooves or incisions, noting any distinct smell, assessing its resistance to moisture, and taking necessary safety precautions. By being able to identify pressure treated wood, you can ensure that you are using the appropriate materials for your construction projects.

Visual Clues: How to Spot Pressure Treated Wood

Pressure treated wood is commonly used in outdoor construction projects due to its durability and resistance to rot and insect damage. However, it can sometimes be challenging to identify pressure treated wood just by looking at it. In this section, we will discuss some visual clues that can help you spot pressure treated wood.

1. Greenish Hue

One of the most common indicators of pressure treated wood is its greenish hue. Pressure treated wood is treated with chemicals that give it a green tint, which is often more noticeable on freshly cut surfaces. Keep in mind that this green color can fade over time due to exposure to sunlight and weathering.

2. Wood Grain

Another visual clue to look for is the wood grain pattern. Pressure treated wood tends to have a more pronounced and distinct wood grain compared to untreated wood. This is because the pressure treatment process can alter the appearance of the wood fibers.

3. Check for Stamps or Labels

Many pressure treated wood products come with stamps or labels that indicate they have been treated. These stamps or labels may include information such as the type of treatment used, the retention level of the chemicals, and the manufacturer’s name. Look for these markings on the end grain or the surface of the wood.

4. Moisture Content

Pressure treated wood is typically more resistant to moisture compared to untreated wood. You can check the moisture content of the wood by touching it or using a moisture meter. If the wood feels damp or has a higher moisture reading, it is likely pressure treated.

5. Fastener Corrosion

Pressure treated wood contains chemicals that can accelerate the corrosion of certain metals. If you notice rust or corrosion around nails, screws, or other fasteners in the wood, it could be an indication that the wood is pressure treated.

6. Use of Chemicals

Pressure treated wood is treated with chemicals such as copper-based compounds. These chemicals help protect the wood against decay and insect damage. If you see signs of chemical treatment, such as a greenish residue or discoloration, it is likely pressure treated wood.

7. Consider the Application

Lastly, consider the purpose and location of the wood. Pressure treated wood is commonly used in outdoor applications, such as decking, fences, and garden furniture. If the wood is exposed to moisture or in direct contact with the ground, there is a higher chance that it is pressure treated.

By paying attention to these visual clues, you can confidently identify pressure treated wood and make informed decisions for your outdoor projects.

Simple Tests to Determine if Wood has been Pressure Treated

Pressure treated wood is commonly used in outdoor projects such as decking, fences, and playground equipment. It is treated with chemicals to protect it from rot, decay, and insect damage. However, it is not always easy to tell if a piece of wood has been pressure treated or not. In this section, we will discuss some simple tests that you can perform to determine if wood has been pressure treated.

1. Look for a Greenish Hue

One of the easiest ways to determine if wood has been pressure treated is by looking for a greenish hue. Pressure treated wood is often treated with chemicals that give it a distinct green color. Inspect the surface of the wood carefully, especially in areas where it has been cut or exposed. If you notice a greenish tint, there is a good chance that the wood has been pressure treated.

2. Check for a Stamp or Label

Another way to determine if wood has been pressure treated is by checking for a stamp or label. Pressure treated wood is typically marked with a stamp or label that indicates the type of treatment it has undergone. Look for these markings on the ends or edges of the wood. The stamp may include information such as the treatment type (e.g., ACQ, CA, or MCQ) and the level of treatment (e.g., above ground or ground contact).

3. Conduct a Water Test

A water test can also help you determine if wood has been pressure treated. Simply pour a small amount of water onto the surface of the wood and observe what happens. If the water is quickly absorbed by the wood, it is likely untreated. However, if the water forms droplets or beads on the surface, it indicates that a water repellent has been applied to the wood, which is a common characteristic of pressure treated wood.

4. Use a Moisture Meter

A moisture meter can be a useful tool for determining if wood has been pressure treated. These devices measure the moisture content of the wood, which can give you an indication of whether or not it has been treated. Pressure treated wood typically has a higher moisture content compared to untreated wood. By using a moisture meter, you can compare the moisture levels of different pieces of wood to identify if any of them have been treated.

In summary, determining if wood has been pressure treated can be done through several simple tests. By looking for a greenish hue, checking for a stamp or label, conducting a water test, and using a moisture meter, you can quickly and easily identify if the wood you are working with has undergone pressure treatment. These tests can help ensure that you use the appropriate safety measures when handling and working with the wood.

Key Indicators of Pressure Treated Wood: What to Look for

When it comes to choosing the right wood for outdoor projects, pressure treated wood is a popular choice due to its durability and resistance to decay and insect damage. However, not all pressure treated wood is created equal. There are certain key indicators that can help you determine the quality and effectiveness of pressure treated wood. In this section, we will discuss what to look for when selecting pressure treated wood for your projects.

1. End Tag or Label

One of the first things to look for when buying pressure treated wood is an end tag or label. This tag provides important information about the wood, such as the type of preservative used, the retention level of the preservative, and any special features or certifications. Make sure to check the end tag or label to ensure that you are getting the right type of pressure treated wood for your needs.

2. Color

The color of pressure treated wood can also be an indicator of its quality. Freshly treated wood typically has a greenish tint due to the copper-based preservative used in the treatment process. Over time, the color may fade to a grayish or brownish tone. Avoid purchasing pressure treated wood that has a black or dark brown color, as it may indicate that the wood has been exposed to moisture and could be compromised.

3. Moisture Content

The moisture content of pressure treated wood is an important factor to consider. Wood with a higher moisture content is more likely to shrink, warp, or crack as it dries. To check the moisture content, you can use a moisture meter or simply feel the wood with your hand. Ideally, the wood should feel slightly damp but not wet to the touch.

4. Check for Cracks or Splits

Inspect the surface of the pressure treated wood for any cracks or splits. These defects can weaken the wood and make it more susceptible to decay or insect damage. It is important to choose wood that is free from major cracks or splits to ensure its longevity and structural integrity.

5. Check for Warping

Warping is a common issue with pressure treated wood, especially if it has not been properly stored or dried. Check for any signs of warping, such as bowing or twisting. While some degree of warping is natural, excessive warping can affect the performance and appearance of your project.

6. Grade and Quality

Pressure treated wood is available in different grades and quality levels. The grade indicates the strength and appearance of the wood, while the quality refers to the overall condition and treatment of the wood. Higher grade and quality woods are generally more expensive but offer better performance and longevity.

7. Environmental Considerations

Lastly, it is important to consider the environmental impact of the pressure treated wood you choose. Look for wood that has been treated with preservatives that are deemed safe for residential use and have minimal environmental impact. Look for certifications such as the Environmental Protection Agency’s (EPA) approval or the Forest Stewardship Council (FSC) certification.

Summary

Choosing the right pressure treated wood for your outdoor projects is essential for ensuring their durability and longevity. Key indicators to look for include the presence of an end tag or label, the color of the wood, moisture content, cracks or splits, warping, grade and quality, and environmental considerations. By paying attention to these indicators, you can select the best pressure treated wood that meets your needs and provides long-lasting performance.

FAQs

How can you tell if wood is pressure treated?

Pressure-treated wood is commonly identified by its greenish-brown color, which is a result of the chemicals used in the treatment process. You may also notice small incisions or punctures on the surface of the wood, which are made during the treatment to allow the chemicals to penetrate.

Conclusion:

In summary, determining whether wood is pressure treated can be done by observing certain visual cues and information. These include looking for a greenish tint or an incised stamp that indicates the wood has been treated. Additionally, checking the wood’s label or asking the supplier for clarification can provide confirmation. It is crucial to identify pressure-treated wood accurately as it offers enhanced resistance to decay and insect damage, making it suitable for outdoor applications. By being aware of the signs and labels associated with pressure-treated wood, you can ensure the appropriate use and maintenance of your wooden projects.