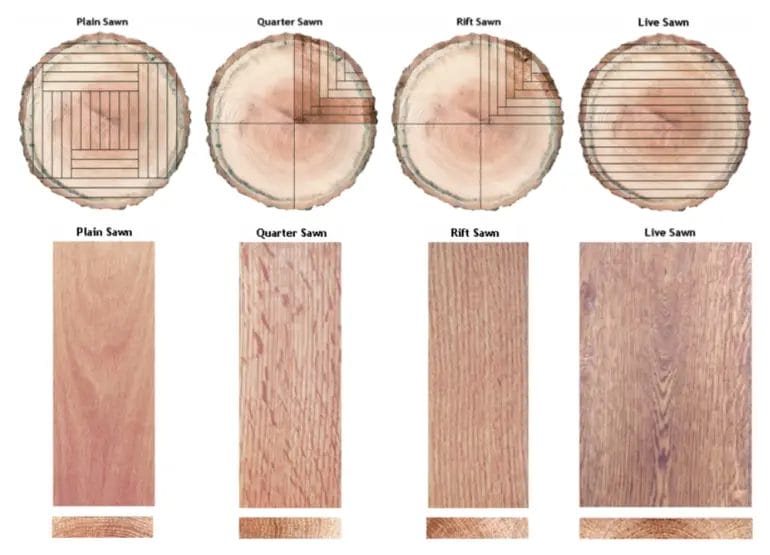

Quartersawn wood is a type of lumber that has been cut in a specific way to enhance its stability and appearance. Unlike plain sawn or flat sawn wood, which is cut parallel to the growth rings, quartersawn wood is cut at a 90-degree angle, resulting in a unique grain pattern that showcases beautiful medullary rays.

This cutting technique not only enhances the visual appeal of the wood but also makes it more resistant to warping and shrinking. Quartersawn wood is highly sought after for its durability, strength, and distinctive look, making it ideal for furniture, cabinetry, and flooring projects.

Due to its desirable qualities, quartersawn wood is often considered a premium option and commands a higher price in the market. Its unique grain pattern and superior stability make it a popular choice for those seeking high-quality, long-lasting wood products.

Quartersawn vs. Plain Sawn: Understanding the Key Differences

When it comes to woodworking projects, the type of wood you choose can greatly impact the outcome. Two popular options are quartersawn and plain sawn wood. Understanding the key differences between these two types of wood can help you make more informed decisions for your projects.

Quartersawn Wood

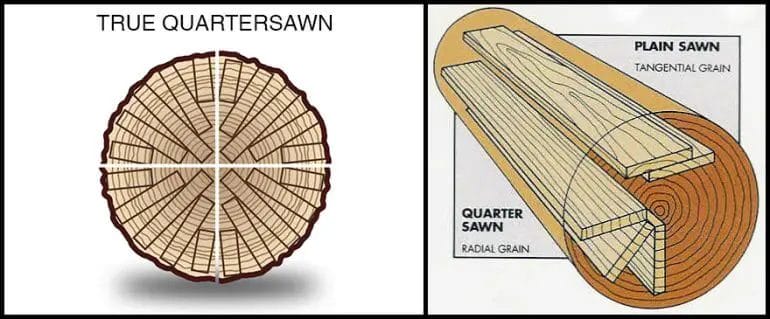

Quartersawn wood refers to lumber that is cut in a specific way to achieve a unique grain pattern. The log is first cut into quarters, hence the name, and then each quarter is cut into boards. This cutting method produces wood with the annual rings approximately perpendicular to the face of the board.

One of the most notable characteristics of quartersawn wood is its distinctive grain pattern. It features beautiful straight or wavy lines that run across the width of the board, giving it a unique and attractive appearance. This type of grain pattern is highly sought after in furniture making and other fine woodworking projects.

Quartersawn wood also has several advantages over plain sawn wood. It tends to be more stable and less prone to warping or twisting. This is because the grain runs vertically through the board, providing greater strength and resistance to movement. Additionally, quartersawn wood is less likely to develop cracks or splits, making it ideal for projects that require durability.

Plain Sawn Wood

Plain sawn wood, also known as flat sawn wood, is the most common and straightforward method of cutting lumber. It involves cutting the log into planks by slicing it parallel to its growth rings. This method produces boards with the familiar cathedral or arch-shaped grain pattern.

Unlike quartersawn wood, plain sawn wood has a less uniform grain pattern. It often features a mix of straight and wavy lines, which can be visually appealing to some woodworkers. However, it may not have the same level of desirable grain figure as quartersawn wood.

One advantage of plain sawn wood is that it is more cost-effective compared to quartersawn wood. Since it requires less processing and cutting, it is generally less expensive to produce. This makes plain sawn wood a popular choice for projects where the aesthetics of the grain pattern are not the main focus.

It is worth noting that plain sawn wood may be more prone to movement and dimensional changes compared to quartersawn wood. It can be more susceptible to warping, twisting, and cupping, especially in changing humidity conditions. However, with proper techniques and precautions, these issues can be minimized.

Impact on Projects

The choice between quartersawn and plain sawn wood largely depends on the specific requirements and aesthetics of your project. Quartersawn wood is often favored for its unique grain pattern, stability, and durability, making it a popular choice for high-end furniture, cabinetry, and musical instruments.

On the other hand, plain sawn wood can be a more budget-friendly option for projects where the distinct grain pattern is not a priority. It is commonly used in construction, flooring, and general woodworking applications where cost efficiency is important.

In summary, understanding the key differences between quartersawn and plain sawn wood allows you to make informed decisions based on your project’s requirements and desired aesthetics. Whether you choose the unique grain of quartersawn wood or the cost-effectiveness of plain sawn wood, both options offer their own advantages for various woodworking applications.

Best Species for Quartersawn Wood

Quartersawn wood is highly sought after for its unique grain pattern and superior stability. It is the result of cutting a log into quarters and then slicing the boards perpendicular to the growth rings. This method of sawing enhances the natural beauty of the wood, creating a distinct appearance that is prized by woodworkers and furniture makers. While many wood species can be used for quartersawn applications, there are some species that are particularly well-suited for this purpose. In this section, we will explore the top wood species that are ideal for quartersawn wood and their unique characteristics.

Oak

Oak is one of the most popular choices for quartersawn wood due to its prominent grain pattern and durability. White oak and red oak are the two main varieties used for quartersawn applications. White oak has a straight grain pattern with occasional rays and a light golden color. It is known for its excellent strength and resistance to decay, making it suitable for both indoor and outdoor projects. Red oak, on the other hand, has a more pronounced grain pattern with reddish undertones. It is slightly less durable than white oak but is still a popular choice for furniture, flooring, and cabinetry.

Maple

Maple is another great option for quartersawn wood, especially hard maple. It has a fine, even texture with a subtle grain pattern that becomes more pronounced when quartersawn. Quartersawn maple has a distinctive appearance with light-colored sapwood and reddish-brown heartwood. It is known for its strength, stability, and resistance to wear, making it a popular choice for flooring, cutting boards, and musical instruments.

Cherry

Cherry wood is highly regarded for its beautiful color and smooth grain pattern. Quartersawn cherry exhibits a straight grain with occasional wavy or curly figures, adding visual interest to any project. It starts off with a light pinkish-brown hue and develops a rich reddish-brown patina over time. Cherry wood is relatively soft compared to oak and maple, making it an excellent choice for furniture, cabinets, and decorative trim.

Walnut

Known for its rich, dark color and striking grain pattern, walnut is a popular choice for quartersawn applications. Quartersawn walnut features a straight grain with occasional curls or waves, giving it a unique and luxurious appearance. It starts off as a light brown color and deepens to a rich chocolate brown with age. Walnut is prized for its durability, stability, and natural beauty, making it a popular choice for high-end furniture, paneling, and flooring.

Mahogany

Mahogany is a tropical hardwood that is widely used for its durability, stability, and rich color. Quartersawn mahogany exhibits a straight grain with occasional interlocking patterns, adding visual interest to the wood. It has a medium to dark reddish-brown color that deepens over time, creating a luxurious appearance. Mahogany is commonly used for furniture, cabinetry, and decorative veneers.

In summary, there are several wood species that are well-suited for quartersawn applications. Oak, maple, cherry, walnut, and mahogany are among the top choices due to their unique characteristics and distinctive grain patterns. Whether you are looking to create furniture, flooring, or decorative items, quartersawn wood made from these species will add beauty and elegance to your projects.

Quartersawn Wood Techniques: Learn the various techniques and methods to properly cut and work with quartersawn wood.

Quartersawn wood is a popular choice among woodworkers due to its unique grain pattern and stability. It is obtained by cutting the log into quarters and then slicing it perpendicular to the growth rings. This results in boards with a straight grain and beautiful figuring. However, working with quartersawn wood requires certain techniques and considerations to ensure the best results. In this section, we will explore the different techniques and methods you can use when working with quartersawn wood.

Choosing the Right Wood

When selecting quartersawn wood for your project, it is important to choose the right wood species. Not all woods exhibit the same characteristics when quartersawn. Some species, such as oak and mahogany, are well-known for their stunning quartersawn figure. Others, like pine or poplar, may not show as much figure but still offer the benefits of stability and durability.

Pay attention to the color, grain pattern, and figuring of the wood. Quartersawn wood often features medullary rays, also known as ray flecks, which can add visual interest to your project. Additionally, consider the moisture content of the wood and ensure it is properly dried to prevent warping or cracking.

Cutting Quartersawn Wood

The first step in working with quartersawn wood is cutting it into the desired dimensions. To do this, you will need a table saw or a bandsaw equipped with a high-quality blade. Begin by setting your saw’s blade to a 90-degree angle or slightly less to the fence. This will ensure a clean and precise cut.

Place the quartersawn board flat against the fence and feed it slowly and steadily through the blade. Take extra care to maintain constant pressure against the fence to prevent the wood from drifting. This will result in an accurate and straight cut. Repeat the process for each piece of quartersawn wood you need.

Working with Quartersawn Wood

Quartersawn wood is known for its stability, making it an excellent choice for furniture and other woodworking projects. However, it can also be more difficult to work with compared to other types of wood. Here are a few techniques to keep in mind when working with quartersawn wood:

- Prevent Splitting: Due to the orientation of the grain, quartersawn wood is less likely to split than plain-sawn wood. However, it is still important to pre-drill holes for screws and nails near the edges to prevent splitting.

- Avoid Cupping: Quartersawn wood is less prone to cupping, but it is still important to acclimate the wood to the environment before working with it. Store the wood in the same conditions where the finished piece will be to minimize movement.

- Finishing Techniques: Quartersawn wood can be finished using a variety of techniques, such as staining, oiling, or varnishing. Experiment with different finishes to enhance the grain pattern and bring out the natural beauty of the wood.

Advantages of Quartersawn Wood

Working with quartersawn wood offers several advantages over other types of wood. The unique grain pattern adds visual interest and character to your projects, making them stand out. Quartersawn wood is also more stable and less prone to warping, making it ideal for furniture and flooring applications.

Additionally, quartersawn wood is known for its durability and resistance to wear. The straight grain pattern provides added strength, making it suitable for projects that require stability and longevity.

In summary, knowing the right techniques and methods for working with quartersawn wood is essential for achieving the best results in your woodworking projects. From selecting the right wood species to cutting and working with the wood, each step plays a crucial role in obtaining the desired outcome. By following the tips and techniques outlined in this section, you can confidently work with quartersawn wood and create beautiful, durable, and visually appealing pieces.

Quartersawn Wood in Furniture Making: Uncover the beauty and durability

When it comes to creating stunning and durable furniture pieces, one material that stands out is quartersawn wood. Quartersawn wood, also known as quarter-cut or radial-grain wood, offers unique characteristics that make it highly sought after in the world of furniture making.

Unlike plain-sawn wood, which is the most common type of cut, quartersawn wood is obtained by cutting the log into quarters and then slicing it perpendicular to the growth rings of the tree. This cutting technique results in distinct grain patterns and enhanced stability, making it an ideal choice for furniture makers.

Benefits of Quartersawn Wood:

1. Stability: Quartersawn wood is known for its superior stability compared to plain-sawn wood. The perpendicular grain pattern minimizes the expansion and contraction that occurs with changes in humidity, reducing the risk of warping, cupping, or splitting. This makes quartersawn wood an excellent choice for furniture pieces that need to withstand the test of time.

2. Enhanced Durability: Quartersawn wood is denser and harder than plain-sawn wood, making it more resistant to wear and tear. The tightly packed grain structure provides added strength, allowing the furniture to withstand heavy use and daily wear without compromising its structural integrity.

3. Unique Grain Patterns: One of the most captivating features of quartersawn wood is its distinct grain patterns. The perpendicular cutting technique reveals beautiful medullary rays, also known as flecks or flakes, that create stunning visual effects. These unique patterns add a touch of elegance and character to furniture pieces, making them stand out in any space.

4. Less Pronounced Shrinkage: Quartersawn wood experiences less shrinkage compared to plain-sawn wood. This is due to the way the growth rings are cut, resulting in a more stable and predictable material. This characteristic is particularly desirable for furniture makers, as it ensures that the piece will maintain its shape and size over time.

Applications of Quartersawn Wood:

Quartersawn wood is versatile and can be used in a variety of furniture pieces. Its stability and durability make it an excellent choice for items that require structural integrity and longevity. Some popular applications include:

- Dining tables

- Desks

- Cabinetry

- Bed frames

- Chairs

- Bookcases

Regardless of the specific furniture piece, quartersawn wood adds a touch of sophistication and uniqueness to any design.

Conclusion:

In summary, quartersawn wood offers a combination of beauty, durability, and stability that makes it an ideal choice for furniture making. Its unique grain patterns, enhanced strength, and resistance to warping make it highly sought after by both furniture makers and enthusiasts. Whether you are looking to create a timeless dining table or a stylish bookcase, quartersawn wood is sure to elevate your furniture pieces to a whole new level.

FAQs

What is quartersawn wood?

Quartersawn wood is lumber that has been cut at a specific angle to the growth rings of a tree. This cutting method produces boards with a distinct grain pattern and increased stability. Quartersawn wood is known for its straight grain, resistance to warping, and beautiful figure.

Conclusion

In conclusion, quartersawn wood is a unique and highly sought-after type of lumber that offers numerous advantages over plain sawn wood. Its distinctive grain pattern, enhanced stability, and resistance to warping make it a popular choice among woodworkers, furniture makers, and flooring manufacturers.

By cutting the log at a different angle, quartersawn wood showcases beautiful medullary rays that add aesthetic value to any project. Additionally, it is less prone to expansion and contraction, making it ideal for environments with fluctuating humidity levels.

Whether you’re looking to create heirloom-quality furniture or durable hardwood flooring, quartersawn wood is a premium option that promises exceptional beauty and longevity.