Wood can be transformed into a visually stunning piece by making it “pop.” This effect refers to enhancing the natural beauty and highlighting the grain and texture of the wood. Various techniques and products can be used to achieve this, such as staining, sanding, and applying finishes. By bringing out the unique characteristics of the wood, the piece becomes more vibrant, rich, and captivating. Whether it’s a furniture item or a decorative object, making wood pop adds depth and allure to any wooden creation.

Understanding the Science Behind Wood Popping

Wood popping is a phenomenon that occurs when wood, particularly when it is being burned, makes a popping or cracking sound. This can be a common occurrence when using wood in fireplaces, stoves, or campfires. While it may seem like a minor annoyance, understanding the science behind wood popping can help you prevent potential accidents or damage.

What Causes Wood Popping?

Wood popping is primarily caused by the release of moisture trapped within the wood. As the wood is heated, the moisture turns into steam, creating pressure within the wood fibers. This pressure builds up until it reaches a point where it can no longer be contained, resulting in the characteristic popping sound.

The amount and intensity of wood popping can vary depending on several factors:

- Wood Type: Different types of wood have varying moisture content and densities, which can affect the amount of popping that occurs. Hardwoods like oak or hickory tend to produce louder and more frequent pops compared to softwoods like pine or cedar.

- Wood Moisture Content: Wood with higher moisture content will produce more popping as more steam is released during the heating process. Properly seasoned wood with lower moisture content will generally produce less popping.

- Heating Conditions: The temperature and rate at which the wood is heated can also impact the amount of popping. Rapidly increasing the temperature or exposing the wood to intense heat can lead to more pronounced popping.

The Dangers of Wood Popping

While wood popping may initially seem harmless, it can pose potential dangers:

- Projectile Risk: When wood pops, small fragments or embers can be propelled from the fire, posing a risk of injury or starting secondary fires. These fragments can travel significant distances, potentially reaching people or flammable materials nearby.

- Structural Damage: Intense wood popping can cause damage to the fireplace or stove, such as cracking or dislodging bricks or tiles. Over time, this can lead to structural instability and the need for costly repairs.

- Fire Spread: Wood popping can also contribute to an increased risk of fire spread within the vicinity. Embers or burning wood fragments can ignite nearby flammable materials, leading to uncontrolled fires.

Preventing Wood Popping

Fortunately, there are several measures you can take to minimize or prevent wood popping:

- Properly Seasoned Wood: Use well-seasoned wood with moisture content below 20%. This will reduce the amount of moisture available for steam formation and thus reduce popping.

- Avoid Excessive Heat: Gradually increase the heat when starting a fire. Avoid exposing the wood to intense heat too quickly, as this can lead to more aggressive popping.

- Use a Fireplace Screen: Install a fireplace screen or spark guard to contain any popping fragments and prevent them from causing harm.

- Regular Maintenance: Regularly clean and inspect your fireplace or stove to ensure it is in good condition and functioning properly. Damaged or deteriorating components can contribute to more severe wood popping.

In Summary

Wood popping is a natural occurrence caused by the release of steam as wood is heated. While it may seem harmless, it can pose risks such as projectiles, structural damage, and fire spread. By understanding the factors that contribute to wood popping and taking preventive measures, you can enjoy the warmth and ambiance of a wood fire safely and without disruptions.

Tips to Prevent Wood from Popping

Wood popping, also known as wood movement or wood splitting, can occur due to various factors such as changes in humidity, improper drying, or improper installation. Popping wood can be not only unsightly but also lead to structural damage if left untreated. In this section, we will discuss some effective tips to prevent wood from popping and ensure the longevity of your wooden structures.

1. Choose the Right Type of Wood

Not all types of wood are prone to popping. Some woods, such as oak, ash, and hickory, are more stable and less likely to split than others like pine or cedar. When selecting wood for your project, opt for a stable and durable species to minimize the risk of popping.

2. Properly Season the Wood

One of the main causes of wood popping is improper drying or seasoning. It’s crucial to ensure that the wood has been adequately dried before using it in your project. Green or freshly cut wood contains a high moisture content, which can lead to excessive wood movement. Dry the wood in a well-ventilated area or use a kiln to speed up the drying process.

3. Acclimate the Wood

Before installing the wood, it’s essential to acclimate it to the environment in which it will be used. This is particularly important if there are significant differences in humidity or temperature between the storage area and the installation site. Allow the wood to sit in the installation area for a few days to adjust to the conditions.

4. Use Proper Fasteners

Choosing the right fasteners can significantly reduce the risk of wood popping. Use screws or nails specifically designed for woodworking projects and ensure they are the appropriate length for the thickness of the wood. Avoid using fasteners that are too short, as they may not provide enough support to hold the wood in place.

5. Pre-Drill Holes

When fastening wood together, pre-drilling holes can help prevent wood from splitting. This is especially important when working with hardwoods or near the edges of the wood. Pre-drilling ensures that the fastener goes in smoothly without causing undue stress on the wood fibers.

6. Apply a Protective Finish

Applying a protective finish to the wood can help minimize the effects of humidity changes and reduce the risk of popping. Choose a suitable finish for the type of wood and the intended use of the project. The finish will create a protective barrier, sealing the wood and preventing excessive moisture absorption.

7. Maintain Proper Humidity Levels

Wood is highly sensitive to changes in humidity, which can cause it to expand or contract. To prevent popping, it’s essential to maintain stable humidity levels in the environment where the wood is installed. Use a humidifier or dehumidifier as necessary to keep the humidity within the recommended range for the specific type of wood.

8. Avoid Excessive Sun Exposure

Direct sunlight can cause wood to dry out and become more prone to popping. Whenever possible, protect wood structures from prolonged exposure to direct sunlight. Use shades, curtains, or UV-blocking coatings to reduce the impact of UV rays on the wood’s surface.

9. Keep the Wood Clean and Well-Maintained

Dirt, dust, and debris can accumulate on the surface of the wood, causing moisture retention and potential damage. Regularly clean the wood with a gentle cleaner and ensure it is thoroughly dry before applying any finishes or protective coatings. Additionally, inspect the wood periodically for any signs of damage or wear and make necessary repairs promptly.

By following these tips, you can significantly reduce the risk of wood popping and ensure the longevity and appearance of your wooden structures. Remember to choose the right type of wood, properly season and acclimate it, use proper fasteners, and maintain optimal humidity levels. Regular maintenance and care will go a long way in preventing wood from popping and preserving its beauty.

How to Safely Handle Wood That Pops

Working with wood can be a rewarding and fulfilling experience. However, there are certain challenges that woodworkers may encounter, one of which is wood that pops or splinters during the woodworking process. This can be dangerous and cause injuries if not handled properly. In this section, we will discuss some essential tips and techniques to safely handle wood that pops.

1. Wear Protective Gear

Before you start working with wood, it is crucial to wear the appropriate protective gear to minimize the risk of injuries. Ensure that you have safety goggles, gloves, and a dust mask. Safety goggles will protect your eyes from flying debris, while gloves will provide a barrier against sharp edges and splinters. Additionally, a dust mask will help you avoid inhaling harmful wood particles.

2. Use the Right Tools

Using the correct tools for the job can significantly reduce the chances of wood popping or splintering. Ensure that you are using sharp cutting tools, such as chisels or saw blades, as dull tools are more likely to cause tearing and splintering. Additionally, consider using a slow feed rate and the appropriate cutting techniques to minimize the stress on the wood.

3. Identify the Problematic Areas

Prior to starting your woodworking project, carefully inspect the wood for any potential problem areas. Look for knots, cracks, or other defects that may cause the wood to pop or splinter. By identifying these areas in advance, you can plan accordingly and take extra precautions when working with them.

4. Support the Wood Properly

Properly supporting the wood during the woodworking process is essential to prevent it from popping or splintering. Use clamps or vices to secure the wood in place, ensuring that it is stable and well-supported. This will help to minimize any movement that may lead to wood popping.

5. Make Relief Cuts

If you are working with a particularly problematic piece of wood that is prone to popping or splintering, consider making relief cuts. Relief cuts are small, strategic cuts made along the edges of the wood to release tension and prevent further splitting. This technique can help to alleviate stress and reduce the chances of the wood popping.

6. Take Your Time

Rushing through a woodworking project can increase the likelihood of wood popping or splintering. Take your time and work slowly and deliberately. By using a steady pace, you can maintain control over the tools and minimize unnecessary pressure on the wood. This will help reduce the risk of wood popping and the subsequent injuries.

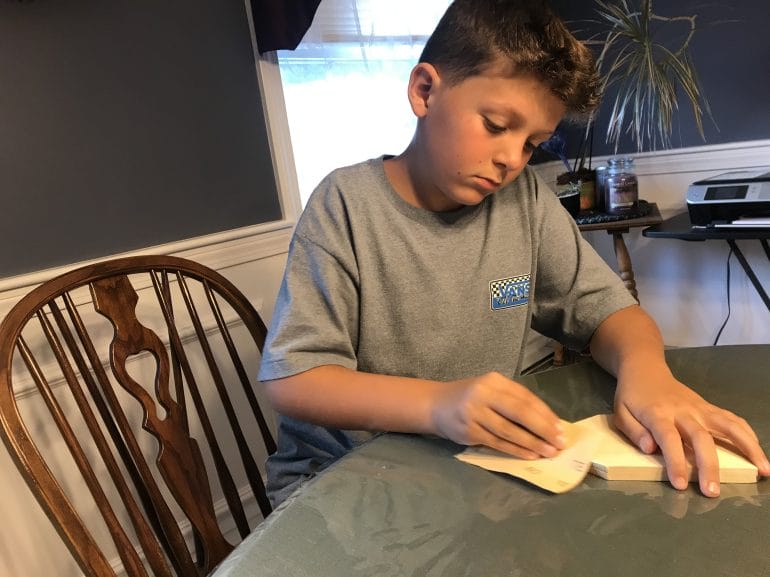

7. Sand and Finish Carefully

Once you have completed the woodworking project, it is important to sand and finish the wood carefully. Sanding the wood smooths out any rough edges or splinters that may have occurred during the process. Apply a protective finish, such as varnish or wood oil, to further enhance the wood’s durability and reduce the chances of future popping.

In summary, handling wood that pops requires caution and proper techniques. By wearing protective gear, using the right tools, identifying problem areas, supporting the wood, making relief cuts, working at a steady pace, and sanding and finishing carefully, you can reduce the risk of wood popping or splintering. Remember, safety should always be the top priority when working with wood.

Effective Ways to Repair Popped Wood

Wood is a popular material used in many construction and furniture projects due to its natural beauty and durability. However, over time, wood can experience issues such as popping, which can compromise its integrity. Popped wood occurs when the wood fibers separate from each other, causing a noticeable gap or bubble on the surface. Fortunately, there are effective methods to repair popped wood and restore its strength and appearance. In this section, we will explore some of these repair techniques.

Identify the Cause of Popped Wood

Before jumping into the repair process, it is vital to identify the underlying cause of the popped wood. This will help determine the appropriate repair method and prevent further damage in the future. Popped wood can occur due to various factors, including moisture changes, improper installation, or natural aging of the wood. Once you have identified the cause, you can proceed with the right repair approach.

Glue and Clamp Method

One common technique to repair popped wood is the glue and clamp method. This method involves applying wood glue into the popped area and then using clamps to hold the wood together until the glue dries. To begin, gather the necessary materials such as wood glue, clamps, a putty knife, and sandpaper. First, clean the popped area by removing any debris or loose wood fibers with a putty knife. Apply a generous amount of wood glue into the gap and use a clamp to hold the popped wood tightly together. Leave the clamp in place until the glue fully dries. Once the glue is dry, remove the clamp and sand the repaired area smooth.

Wood Filler

If the popped wood has resulted in a larger gap or hole, using a wood filler can provide a more seamless repair. Wood filler is a paste-like substance that is specifically designed for filling gaps and holes in wood surfaces. Start by cleaning the damaged area and removing any loose debris. Then, apply the wood filler into the gap, ensuring it is evenly distributed. Use a putty knife to smooth out the filler and remove any excess. Allow the filler to dry according to the manufacturer’s instructions. Once dry, sand the area to create a smooth and level surface. You can then finish the repair by staining or painting the wood to match the surrounding surface.

Wood Screws or Nails

In some cases, using wood screws or nails can provide a quick and effective solution for repairing popped wood. This method is especially useful for larger gaps or areas where the wood fibers have completely separated. Start by aligning the popped wood pieces back together and secure them in place using wood screws or nails. Make sure to countersink the screws or nails to ensure they are flush with the surface. Once the wood is secured, use a wood filler or putty to fill any remaining gaps or holes. Sand the area smooth and finish it as desired.

Preventing Future Popped Wood

While repairing popped wood is essential, taking preventive measures can help avoid future issues. Here are some tips to prevent wood from popping:

- Ensure proper installation and use appropriate fasteners for the wood project.

- Apply a protective finish, such as varnish or sealant, to the wood surface to minimize moisture absorption.

- Avoid exposing wood to extreme temperature and humidity changes.

- Maintain a consistent indoor environment to minimize wood expansion and contraction.

In summary, repairing popped wood can be done effectively using various methods such as the glue and clamp technique, wood filler, or securing with wood screws or nails. Identifying the cause of the popped wood and taking preventive measures can help maintain the integrity and beauty of wood surfaces for years to come.

FAQs

What causes wood to pop?

Wood can pop or crackle due to the release of trapped moisture or volatile gases when heated. The sudden expansion of these substances within the wood can create popping sounds. This phenomenon is commonly observed in firewood or when using wood in a fireplace or wood-burning stove.

Why does wood pop when burning?

When wood is burned, the heat causes the moisture inside the wood to turn into steam. This steam expands rapidly, causing the wood to crack and pop. Additionally, the combustion process can release gases and resins that can also contribute to the popping sound.

Is popping wood dangerous?

Popping wood itself is not typically dangerous. However, it’s important to maintain a safe distance and carefully monitor the fire to ensure that sparks or embers don’t escape and cause unintended fires. It is advisable to use a fireplace screen or take necessary precautions to prevent any potential hazards.

Conclusion:

In conclusion, understanding what makes wood pop can enhance your woodworking projects and create stunning finished products. By employing various techniques such as sanding, staining, and applying a topcoat, you can bring out the natural beauty and character of wood. Additionally, selecting the right type of wood with distinctive grain patterns and figuring can add further visual interest. Whether you’re crafting furniture, cabinetry, or decorative items, the art of making wood pop involves a balance between technique and choosing the perfect wood species. So, experiment with different methods and woods to achieve that eye-catching “wow” factor in your woodworking creations.