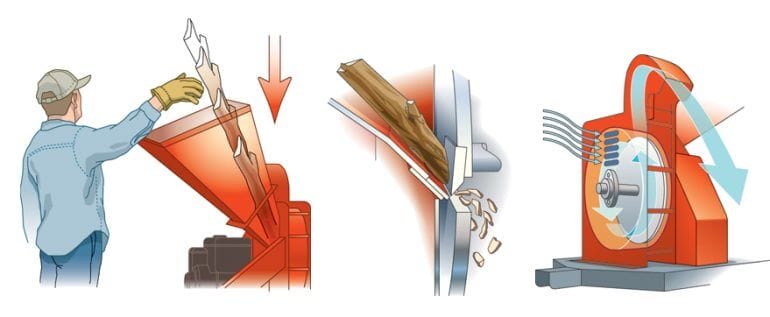

A wood chipper is a powerful machine that is used to convert tree branches, trunks, and other wood waste into small, manageable chips. It works by feeding the wood into a hopper, where it is then pulled in by rotating blades or discs. These blades or discs cut the wood into smaller pieces, which are then expelled through a discharge chute. Wood chippers are commonly used in landscaping, gardening, and forestry industries to quickly and efficiently process wood waste.

Types of wood chippers: Which one is right for you?

Wood chippers are essential tools for anyone working with wood, whether it’s for landscaping, gardening, or firewood production. They are designed to efficiently shred branches, twigs, and other organic debris into smaller, more manageable pieces. However, not all wood chippers are created equal. There are several types of wood chippers available in the market, each with its own unique features and capabilities. In this section, we will explore the different types of wood chippers and help you determine which one is right for you.

1. Electric Wood Chippers

Electric wood chippers are powered by electricity and are perfect for small to medium-sized yards. They are lightweight, portable, and easy to maneuver, making them ideal for homeowners and hobbyists. Electric wood chippers are relatively quieter compared to their gas-powered counterparts, making them more suitable for residential areas. They are also eco-friendly as they produce zero emissions. Electric wood chippers are best suited for chipping smaller branches and twigs, typically less than 2 inches in diameter.

2. Gas-Powered Wood Chippers

Gas-powered wood chippers are more powerful and designed for heavy-duty use. They are commonly used by professionals, landscapers, and arborists who deal with larger branches and trees. Gas-powered wood chippers are equipped with powerful engines that can chip branches up to 4 inches in diameter or more. They offer greater mobility and can be used in remote areas or construction sites where electricity may not be readily available. However, gas-powered wood chippers tend to be louder and produce emissions, making them more suitable for commercial or rural areas.

3. PTO Wood Chippers

PTO (Power Take-Off) wood chippers are heavy-duty machines that are typically powered by tractors or other heavy equipment. They are designed to handle large-scale wood chipping tasks and are commonly used in forestry and agricultural operations. PTO wood chippers are capable of chipping branches and trees of various sizes, often up to 10 inches in diameter or more. They are highly efficient and can process large volumes of wood in a short amount of time. However, PTO wood chippers require a tractor or compatible equipment to operate, making them less suitable for casual users or small-scale projects.

4. Chipper Shredder Combos

Chipper shredder combos are versatile machines that combine the functions of a wood chipper and a shredder. They are designed to handle both chipping and shredding tasks, making them a popular choice for homeowners and gardeners. Chipper shredder combos can chip branches and shred leaves, garden waste, and other organic material. They are perfect for mulching and composting applications. However, it’s important to note that chipper shredder combos may not be as powerful as dedicated wood chippers or shredders.

5. Handheld Wood Chippers

Handheld wood chippers, also known as chipper shredder vacuums, are compact and portable machines that are operated manually. They are ideal for small-scale tasks and are commonly used for cleaning up small branches, leaves, and other debris in the yard. Handheld wood chippers typically have a lower capacity and are best suited for light-duty applications. They are perfect for homeowners who need a simple and convenient solution for occasional yard cleanup.

In summary, when choosing a wood chipper, it’s important to consider the size of your property, the type and size of the wood you will be chipping, and the frequency of use. Electric wood chippers are suitable for smaller yards and lighter applications, while gas-powered and PTO wood chippers are better suited for heavy-duty and professional use. Chipper shredder combos offer versatility for homeowners, and handheld wood chippers provide a convenient option for small-scale yard cleanup. Assess your specific needs and choose the type of wood chipper that best fits your requirements.

Step-by-step guide to operating a wood chipper safely

Wood chippers are powerful machines used to turn branches and other yard waste into valuable wood chips. While they can be a convenient tool for homeowners and professionals alike, it’s important to operate them safely to prevent accidents and injuries. In this section, we will provide a step-by-step guide to operating a wood chipper safely.

Step 1: Read the manual

Before operating a wood chipper, it’s essential to read the manufacturer’s manual thoroughly. The manual provides important information about the specific model you are using, including safety precautions, maintenance instructions, and operational guidelines. Familiarize yourself with the manual to ensure you understand the machine’s features and limitations.

Step 2: Wear appropriate safety gear

When operating a wood chipper, it’s crucial to wear the right safety gear to protect yourself from potential hazards. This includes:

- Safety goggles or a face shield to protect your eyes from flying debris.

- Hearing protection, such as earplugs or earmuffs, to prevent hearing damage from the machine’s noise.

- Heavy-duty work gloves to protect your hands from sharp branches and wood chips.

- Steel-toed boots with non-slip soles to protect your feet from falling debris.

- A hard hat to protect your head from overhead hazards.

- Fitted clothing to avoid any loose clothing that could get caught in the machine.

Step 3: Clear the work area

Prior to operating the wood chipper, it’s important to clear the work area of any potential obstructions or hazards. Remove any rocks, debris, or other objects that could be thrown out by the machine. Ensure there is enough space for the wood chips to be discharged safely without causing any damage or injury.

Step 4: Inspect the wood chipper

Before starting the wood chipper, thoroughly inspect it for any signs of damage or malfunction. Check for loose or missing parts, frayed wires, and damaged blades. Ensure all safety guards and shields are in place and functioning properly. If you notice any issues, do not operate the machine and contact a professional for repairs.

Step 5: Start the wood chipper

Once you have completed the necessary safety checks, it’s time to start the wood chipper. Follow the manufacturer’s instructions for starting the machine, including any specific starting procedures or precautions. Make sure the discharge chute is positioned in a safe direction away from people, buildings, and other objects.

Step 6: Feed the wood chipper properly

When feeding the wood chipper, it’s essential to follow proper techniques to avoid accidents. Only feed branches and yard waste that are within the machine’s specified capacity. Do not force materials into the chipper if they are too large or tangled. Instead, trim or untangle them beforehand. Use a push stick or a long branch to guide the material into the chipper, keeping your hands and body at a safe distance.

Step 7: Monitor the wood chipper

While the wood chipper is in operation, it’s important to continuously monitor it for any signs of problems or malfunction. Keep an eye on the discharge chute to ensure the wood chips are being discharged properly. If you notice any unusual noises, vibrations, or other issues, stop the machine immediately and investigate the cause before continuing.

Step 8: Shut down the wood chipper

Once you have finished using the wood chipper, follow the manufacturer’s instructions for shutting it down safely. Allow the machine to come to a complete stop before performing any maintenance or cleaning tasks. Never leave the wood chipper unattended while it is running.

Step 9: Clean and maintain the wood chipper

Regular cleaning and maintenance are essential to keep the wood chipper in optimal condition. After each use, remove any wood chips, debris, or clogs from the machine. Inspect the blades for sharpness and replace them if necessary. Follow the manufacturer’s maintenance schedule for oil changes, filter replacements, and other routine tasks.

In summary, operating a wood chipper safely requires careful attention to detail and adherence to proper procedures. By following this step-by-step guide and prioritizing safety precautions, you can ensure a safe and efficient wood chipping experience.

Essential Maintenance Tips to Keep Your Wood Chipper Running Smoothly

Wood chippers are an essential tool for anyone working with wood, whether it’s for landscaping, gardening, or even industrial purposes. These powerful machines make quick work of branches, twigs, and other wood debris, turning them into valuable mulch or compost. However, like any machinery, wood chippers require regular maintenance to ensure optimal performance and longevity. In this section, we will discuss some essential maintenance tips to keep your wood chipper running smoothly.

1. Read the Manual

Before you start using your wood chipper, it’s crucial to read and understand the manufacturer’s manual thoroughly. The manual will provide you with essential information about the specific maintenance requirements of your wood chipper model. It will outline the recommended maintenance schedule, including oil changes, filter replacements, and other important tasks.

2. Clean and Inspect Regularly

Regular cleaning and inspection are vital for the optimal performance of your wood chipper. After each use, make sure to clean the machine to remove any wood chips, debris, or other foreign objects that may have accumulated. Pay special attention to areas like the chute, blades, and cutting chamber.

In addition to cleaning, it’s essential to inspect the wood chipper regularly for any signs of wear or damage. Check the blades for sharpness and replace them if necessary. Inspect the belts, pulleys, and bearings for any signs of wear or misalignment. By catching these issues early on, you can prevent costly repairs and ensure the safe operation of your wood chipper.

3. Keep Blades Sharp

The blades are the heart of your wood chipper, and keeping them sharp is crucial for efficient chipping. Dull blades not only reduce the chipper’s performance but also put extra strain on the engine and other components. Regularly inspect the blades for sharpness and sharpen them as needed. If the blades are chipped or damaged, replace them immediately to avoid further damage to the machine.

4. Check and Change Oil

Proper lubrication is essential for the smooth operation of any machinery, including wood chippers. Regularly check the oil levels and condition according to the manufacturer’s recommendations. If the oil appears dirty or low, it’s time for an oil change. Use the recommended oil type for your specific wood chipper model. Additionally, don’t forget to check and change the oil filters as needed.

5. Replace Filters and Spark Plugs

Filters, such as air filters and fuel filters, play a crucial role in maintaining the performance and longevity of your wood chipper. Regularly inspect these filters and replace them as recommended by the manufacturer. Similarly, spark plugs should also be checked and replaced if worn out. Clean filters and spark plugs ensure proper airflow and fuel combustion, leading to better performance and fuel efficiency.

6. Maintain Proper Belt Tension

Belts drive various components of your wood chipper, and maintaining the correct tension is essential for smooth operation. Inspect the belts regularly for signs of wear or stretching and adjust the tension if needed. Loose or worn-out belts can lead to reduced performance and even damage to other parts of the machine.

7. Store Properly

When not in use, it’s crucial to store your wood chipper properly. Clean the machine thoroughly and ensure all moving parts are well lubricated. Store it in a dry and secure location, away from the elements. If possible, cover the wood chipper with a protective tarp to prevent dust, moisture, or debris from accumulating on the machine.

8. Schedule Professional Servicing

While regular maintenance can go a long way in keeping your wood chipper in top shape, it’s also advisable to schedule professional servicing at regular intervals. Professional technicians can inspect and service your wood chipper more thoroughly, ensuring that all components are in optimal condition and addressing any potential issues before they become major problems.

Summary

Maintaining your wood chipper is essential to ensure its smooth operation and extend its lifespan. By following these essential maintenance tips, including reading the manual, regular cleaning and inspection, keeping the blades sharp, checking and changing oil, replacing filters and spark plugs, maintaining proper belt tension, proper storage, and scheduling professional servicing, you can keep your wood chipper running smoothly and efficiently for years to come.

Creative Uses for Wood Chips: Recycling and Repurposing the Byproduct

Wood chips are a common byproduct of woodworking and tree removal processes. These small pieces of wood can often be seen as waste, but they actually have a wide range of creative uses. By recycling and repurposing wood chips, we can not only reduce waste but also give them a new life. In this section, we will explore some innovative ways to use wood chips.

1. Mulch for Gardening and Landscaping

One of the most popular uses for wood chips is mulch. Wood chip mulch acts as a protective layer around plants, providing insulation, retaining moisture, and suppressing weed growth. When spread around flower beds, vegetable gardens, or trees, wood chips can enhance the aesthetics of the landscaping while also benefiting the plants.

2. Composting Material

Wood chips are an excellent addition to compost piles. They add carbon, which balances the nitrogen-rich materials such as food scraps and grass clippings. The carbon-to-nitrogen ratio in compost is crucial for efficient decomposition. Wood chips also improve aeration and moisture retention in the compost pile, leading to the production of rich, nutrient-dense compost.

3. Animal Bedding

Wood chips can be used as bedding material for animals such as chickens, horses, or rabbits. The wood chips provide a soft and comfortable surface for the animals to rest on. Additionally, they absorb moisture and odor, keeping the animal’s living environment clean and dry.

4. Pathways and Trails

Wood chips can be used to create natural-looking pathways and trails in gardens, parks, or hiking areas. They provide a soft surface underfoot and help to prevent erosion. Wood chip pathways offer a rustic charm and blend well with the surrounding environment.

5. Biomass for Energy Generation

Wood chips can be converted into biomass fuel for energy generation. Biomass power plants use wood chips as a renewable source of energy. These chips are burned to produce steam, which is then used to generate electricity or heat. By utilizing wood chips for energy production, we reduce our dependency on fossil fuels and contribute to a greener future.

6. Wood Chip Art and Crafts

Wood chips can be transformed into unique art pieces and crafts. They can be used for wood burning art, mosaic designs, or even as materials for sculptures. The natural texture and color variations of wood chips add character and depth to artistic creations.

7. Animal Habitat Enhancement

Wood chips can be used to enhance animal habitats, particularly for wildlife and birds. Creating wood chip piles or placing them in specific areas can provide shelter, nesting materials, and foraging spaces for various creatures. This encourages biodiversity and supports the ecosystem.

8. Erosion Control

Wood chips can be used for erosion control in areas prone to soil erosion, such as slopes or riverbanks. They help to stabilize the soil by preventing water runoff and reducing the impact of raindrops on the ground. Wood chips also promote vegetation growth, which further aids in erosion prevention.

9. Smoking and BBQ Flavoring

Wood chips are commonly used for smoking and flavoring food, particularly in BBQ cooking. Different types of wood chips add distinct flavors to grilled or smoked meats, vegetables, or fish. They can be soaked and placed directly on hot coals or used in smoking chambers to infuse delicious smoky flavors.

10. DIY Projects and Woodworking

Wood chips can be a valuable resource for DIY projects and woodworking. They can be used as filler material for cracks, gaps, or holes in wooden surfaces. Wood chips mixed with glue or resin can create unique textures and patterns for wood crafts and furniture.

As you can see, wood chips have numerous creative uses beyond their initial purpose. By recycling and repurposing wood chips, we can minimize waste and contribute to a more sustainable environment. Whether it’s for gardening, landscaping, crafts, or energy production, wood chips can find a new life in a variety of innovative ways.

FAQs

How does a wood chipper work?

A wood chipper is a machine that processes wood into small, manageable chips. It typically consists of a hopper, a feed mechanism, and a cutting mechanism. The wood is fed into the hopper, where it is pulled in by the feed mechanism and pushed against the rotating blades or rollers of the cutting mechanism. The blades or rollers cut the wood into chips of the desired size, which are then discharged through a chute.

Conclusion

In conclusion, understanding how a wood chipper works can greatly benefit those in the forestry and landscaping industries, as well as homeowners with large yards. By using a combination of sharp blades, high-speed rotation, and a powerful motor, wood chippers efficiently break down tree branches, limbs, and other yard debris into small wood chips. These chips can be used for various purposes, such as mulching, composting, or fuel. Overall, a wood chipper is an essential tool for managing and recycling organic materials, helping to promote sustainability and eco-friendly practices.

Whether you’re clearing fallen branches after a storm or maintaining your garden, a wood chipper offers an efficient and convenient solution for reducing bulky yard waste. By turning this waste into valuable wood chips, you can contribute to a healthier environment while also benefiting from the versatility and practicality of the process. From landscaping professionals to DIY enthusiasts, the functionality of a wood chipper makes it an indispensable tool for any outdoor project.