Yes, you can sublimate on wood to create stunning and personalized designs. Sublimation is a process where heat and pressure are used to transfer vibrant colors onto a variety of materials, including wood. By using specialized sublimation inks and a heat press, you can permanently embed your designs into the wood, resulting in a durable and high-quality finish. Whether you want to create custom signs, plaques, or home decor items, sublimating on wood offers endless possibilities for adding a unique touch to your creations.

Sublimation Printing on Wood: A Step-by-Step Guide

Sublimation printing on wood has become a popular method for creating unique and personalized designs on wooden surfaces. This printing technique allows you to transfer vibrant and high-resolution images onto wood, resulting in stunning and long-lasting prints. Whether you are a DIY enthusiast or a professional, learning how to sublimate print on wood can open up a world of creative possibilities. In this guide, we will walk you through the step-by-step process of sublimation printing on wood.

Materials Needed

Before you begin, make sure you have the following materials:

- A sublimation printer

- Sublimation ink

- Sublimation paper

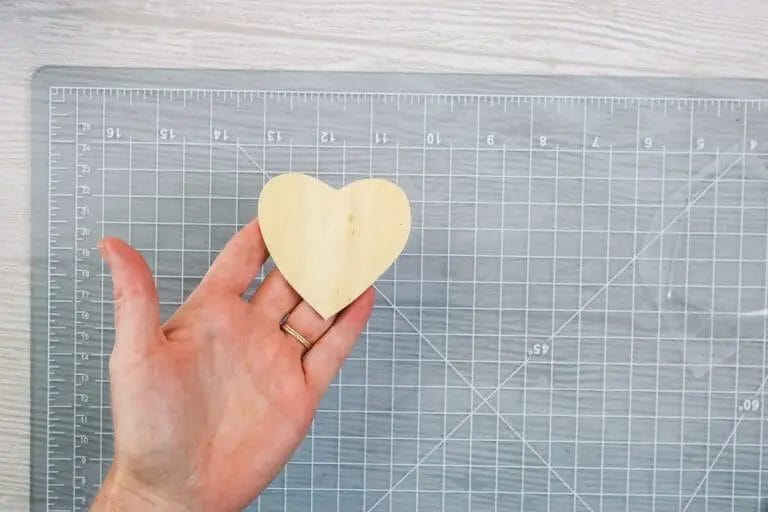

- Wooden blanks

- Heat-resistant tape

- Heat press or sublimation oven

- Heat-resistant gloves

- Protective parchment paper

Step 1: Choose the Right Wood

The first step in sublimation printing on wood is selecting the right type of wood. Opt for a smooth and untreated wooden blank that is suitable for sublimation. Hardwoods such as maple, birch, or cherry work well for this process, as they have a tight grain and provide a smooth printing surface.

Step 2: Prepare the Wooden Surface

Before you can start the printing process, it is essential to prepare the wooden surface. Begin by sanding the wood to create a smooth and even surface. Remove any dust or debris using a clean, lint-free cloth.

Step 3: Design and Print

Now comes the creative part. Design your artwork or image using graphic design software and ensure it is sized correctly to fit your wooden blank. Once you have your design ready, print it onto sublimation paper using a sublimation printer and ink.

Step 4: Transfer the Image

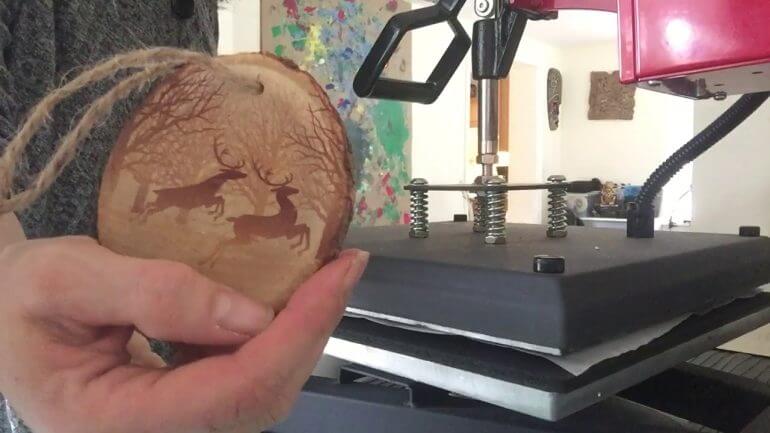

Place your printed sublimation paper face down onto the prepared wooden blank. Use heat-resistant tape to secure the paper in place, ensuring it is taut and wrinkle-free. Then, carefully place the wooden blank with the attached sublimation paper into a heat press or sublimation oven.

Step 5: Apply Heat and Pressure

Follow the manufacturer’s instructions for your heat press or sublimation oven to determine the appropriate temperature and duration for the sublimation process. Generally, temperatures range between 350 to 400 degrees Fahrenheit, and the process takes around 60 to 90 seconds.

Step 6: Remove and Cool

Once the sublimation process is complete, carefully remove the wooden blank from the heat press or oven using heat-resistant gloves. Be cautious as the surface will be hot. Remove the sublimation paper and allow the wooden blank to cool completely before handling.

Step 7: Finishing Touches

After the wooden blank has cooled, you can add any desired finishing touches. Apply a protective coating, such as a clear varnish or wood sealer, to enhance the longevity and durability of the print. Ensure the coating is compatible with sublimation prints.

Summary

Sublimation printing on wood is a creative and exciting way to personalize wooden surfaces with vibrant and high-resolution designs. By following this step-by-step guide, you can learn how to sublimate print on wood and unlock endless possibilities for customizing and decorating wooden blanks. Remember to choose the right wood, prepare the surface, design and print your artwork, transfer and apply heat, and finish with protective coatings for long-lasting results. With practice and experimentation, you can create stunning sublimation prints on wood that will impress others and showcase your artistic flair.

Best Practices for Sublimating Images onto Wood

Sublimation is a popular technique used to transfer images onto various surfaces, including wood. This process involves printing an image onto a special transfer paper with sublimation ink, and then applying heat and pressure to transfer the image onto the wood. Sublimated wood products have a unique and vibrant appearance, making them ideal for personalized gifts, home decor, and promotional items. To ensure the best results when sublimating images onto wood, follow these best practices:

1. Choose the Right Type of Wood

The type of wood you choose plays a crucial role in the sublimation process. It is recommended to use a hardwood with a smooth surface, such as maple, birch, or cherry. Avoid using softwoods or woods with a heavy grain, as they may not provide a smooth and consistent surface for the image transfer.

2. Prepare the Wood Surface

Before sublimating the image onto the wood, it is essential to prepare the surface properly. Start by sanding the wood to create a smooth and even surface. Remove any dust or debris from the surface using a tack cloth or a lint-free cloth. This step ensures better ink absorption and reduces the risk of imperfections in the final result.

3. Adjust the Image for Sublimation

When preparing the image for sublimation, it is important to consider the characteristics of the wood surface. Wood has a natural color and texture, which can affect the appearance of the transferred image. Adjust the image colors and contrast to compensate for these natural variations and ensure a more accurate representation on the wood.

4. Use High-Quality Sublimation Ink and Paper

The quality of sublimation ink and paper directly impacts the final result. Choose high-quality sublimation ink and paper specifically designed for wood sublimation. These products ensure vibrant colors, sharp details, and excellent durability. It is worth investing in reputable brands that specialize in sublimation printing.

5. Properly Align and Secure the Image Transfer

When transferring the image onto the wood, ensure proper alignment and secure the transfer paper in place. Use heat-resistant tape to hold the transfer paper firmly onto the wood surface. This step prevents any movement or misalignment during the sublimation process, resulting in a more precise and accurate image transfer.

6. Apply Heat and Pressure Evenly

Heat and pressure are essential elements in the sublimation process. Use a heat press machine with consistent and even heat distribution. Follow the recommended temperature and time settings provided by the sublimation ink and paper manufacturers. Applying the right amount of pressure is also crucial to ensure proper ink transfer without damaging the wood surface.

7. Allow Sufficient Cooling Time

After the sublimation process, allow the wood to cool down completely before handling or packaging. The cooling process helps the ink molecules bond with the wood fibers, resulting in a more durable and long-lasting image. Rushing the cooling process may lead to smudging or fading of the transferred image.

8. Apply Protective Coating

To enhance the longevity of the sublimated image, consider applying a protective coating to the wood. There are various options available, such as clear polyurethane or lacquer. Apply the coating evenly and let it dry completely before handling the sublimated wood product. The protective coating helps protect the image from scratches, UV damage, and moisture.

9. Test and Experiment

Every wood type and sublimation setup may have slight variations in the transfer process. It is always recommended to test and experiment with different settings, materials, and techniques. This allows you to fine-tune the sublimation process and achieve the best results for your specific setup.

Summary

Sublimating images onto wood can create beautiful and personalized products. By following these best practices, you can ensure optimal results in terms of image quality, durability, and overall appearance. Remember to choose the right type of wood, prepare the surface properly, use high-quality materials, and experiment to find the perfect settings for your sublimation setup. With proper technique and attention to detail, you can create stunning sublimated wood products that will impress your customers or loved ones.

Exploring the Benefits of Sublimation Printing on Wood

Sublimation printing on wood is a unique and innovative method that allows for high-quality and vibrant designs to be transferred onto wooden surfaces. This printing technique involves using heat and pressure to infuse the ink directly into the wood fibers, resulting in a durable, long-lasting, and visually appealing print.

1. Enhanced Durability

One of the major benefits of sublimation printing on wood is its enhanced durability. Unlike traditional printing methods, such as screen printing or vinyl graphics, sublimation printing creates a permanent bond between the ink and the wood fibers. This means that the printed design will not peel, crack, or fade over time, making it ideal for both indoor and outdoor applications.

2. Vibrant and High-Quality Prints

Sublimation printing on wood offers the advantage of producing vibrant and high-quality prints. The heat and pressure applied during the printing process allow the ink to penetrate the wood fibers, resulting in rich and vivid colors that truly stand out. This makes sublimation printing an excellent choice for showcasing detailed artwork, intricate patterns, or striking photographs.

3. Versatility

Another benefit of sublimation printing on wood is its versatility. This printing technique can be applied to various types of wood, including plywood, MDF (medium-density fiberboard), and natural wood. It can also be used on different wooden products, such as signs, plaques, photo frames, furniture, and more. With sublimation printing, the possibilities are endless, allowing for creative and personalized designs.

4. Eco-Friendly Option

Sublimation printing on wood is an eco-friendly option compared to other printing methods. Unlike traditional printing techniques that use solvents and chemicals, sublimation printing uses water-based inks that are non-toxic and environmentally friendly. The process also produces minimal waste, as there is no excess ink or materials left behind.

5. Easy Maintenance

Maintaining sublimation prints on wood is hassle-free. The printed designs are resistant to scratches, moisture, and UV rays, ensuring long-lasting durability. Cleaning the prints is as simple as wiping them with a soft cloth, making them suitable for both residential and commercial use.

6. Customization Options

With sublimation printing on wood, customization options are virtually limitless. Whether you want to personalize a wooden gift, create branded promotional items, or decorate your home or office space, sublimation printing allows for easy customization. You can choose from a variety of designs, fonts, and images to create a unique and personalized finished product.

7. Cost-Effective Solution

In terms of cost, sublimation printing on wood is a cost-effective solution. The process is efficient and does not require any setup or cleanup time. This makes it suitable for both small-scale and large-scale printing projects. Additionally, sublimation printing allows for high-quality results at an affordable price, making it a budget-friendly option for individuals and businesses alike.

Summary

Sublimation printing on wood offers numerous benefits, including enhanced durability, vibrant and high-quality prints, versatility, eco-friendliness, easy maintenance, customization options, and cost-effectiveness. Whether you are looking to create personalized gifts, branded merchandise, or decorative items, sublimation printing on wood is a fantastic choice that combines aesthetics and functionality.

Troubleshooting Common Issues in Sublimation Printing on Wood

Sublimation printing on wood is a popular technique for transferring vibrant and detailed designs onto wooden surfaces. However, like any printing process, it can encounter some common issues that may affect the final result. In this section, we will explore these common issues and provide troubleshooting tips to help you achieve the best possible sublimation prints on wood.

1. Blurry or Faded Prints

If your sublimation prints on wood appear blurry or faded, there could be a few reasons for this problem. Firstly, check the quality of your sublimation paper. Low-quality paper may not hold the ink properly, resulting in blurred or faded prints. Using a higher-quality sublimation paper can help improve the clarity of the prints.

Another possible cause could be improper heat press settings. Ensure that your heat press machine is set to the correct temperature and time for sublimating wood. If the temperature is too low or the pressing time is insufficient, the ink may not sublimate fully, leading to faded prints. Experiment with different heat press settings to find the optimal parameters for achieving vibrant and sharp prints.

Finally, consider the wood surface itself. Sublimation works best on porous surfaces, so make sure the wood is properly prepared for printing. Sanding the surface lightly and applying a sublimation coating can enhance ink absorption, resulting in clearer prints.

2. Color Inconsistency

If you notice color inconsistencies in your sublimation prints on wood, there are a few factors to consider. Firstly, examine your color management system. Inaccurate color profiles or incorrect color settings in your design software can lead to variations in color output. Calibrate your monitor regularly to ensure accurate color representation.

Additionally, pay attention to the color mode and color space settings in your design file. Sublimation printing typically uses the CMYK color mode, so make sure your design is in this color mode to avoid color shifting during the printing process.

Furthermore, the type and quality of wood can impact color consistency. Different wood types absorb ink differently, so test different woods to find the ones that produce the desired color results. Consider using lighter-colored wood for more accurate color reproduction.

3. Image Transfer Issues

If you are experiencing difficulties with image transfer during sublimation printing on wood, several factors might be at play. Firstly, check the pressure applied during the heat press. Insufficient pressure can prevent proper ink transfer, resulting in incomplete or patchy prints. Adjust the pressure settings on your heat press machine to ensure even and consistent pressure across the entire wood surface.

Another common issue is improper image alignment with the wood surface. It is crucial to position the sublimation paper correctly on the wood to achieve accurate image transfer. Use alignment tools or guides to ensure precise positioning and prevent any misalignment issues.

Lastly, be mindful of the humidity levels in your workspace. High humidity can interfere with the sublimation process, affecting ink transfer and image clarity. Maintain optimal humidity levels in your printing environment to minimize potential issues.

4. Uneven or Patchy Coating

Uneven or patchy coating on the wood surface can negatively impact sublimation prints. If you encounter this issue, evaluate your coating application technique. Ensure that you apply the sublimation coating evenly and consistently across the entire wood surface. Utilize proper coating tools, such as foam brushes or spray guns, to achieve a smooth and uniform coating layer.

It is also crucial to follow the manufacturer’s instructions when applying the coating. Some coatings require multiple layers, drying time, or specific application methods. Adhering to these guidelines can help you achieve a more even and durable coating on the wood, resulting in better print quality.

In summary, troubleshooting common issues in sublimation printing on wood involves addressing factors such as paper quality, heat press settings, wood preparation, color management, image alignment, pressure, humidity, and coating technique. By identifying and resolving these issues, you can enhance the overall quality and consistency of your sublimation prints on wood.

Creative Ideas for Personalized Wood Sublimation Products

Wood sublimation products have gained popularity in recent years as a unique and personalized way to decorate your home or give thoughtful gifts. The process involves transferring vibrant and detailed designs onto wooden surfaces using heat and pressure. If you’re looking for creative ideas to explore with personalized wood sublimation products, we have some exciting suggestions for you:

1. Custom Wooden Photo Frames

One of the most popular applications of wood sublimation is creating personalized photo frames. You can choose a favorite photo or create a collage and have it transferred onto a wooden frame. The natural texture and grain of the wood will add warmth and character to your cherished memories.

2. Personalized Wooden Signs

Wooden signs are a great way to add a personal touch to your home or office. You can have custom quotes, family names, or even a special message transferred onto wooden plaques. These signs can be hung on walls or placed on shelves to create a unique and meaningful decor element.

3. Custom Wooden Coasters

Add a touch of elegance to your coffee table or bar with personalized wooden coasters. You can choose to have initials, monograms, or even intricate designs and patterns transferred onto the wooden surface. These coasters not only protect your furniture but also make for a stylish and personalized home accessory.

4. Personalized Wooden Cutting Boards

A personalized wooden cutting board is not only functional but also makes for a beautiful kitchen decor piece. You can have names, quotes, or even intricate designs transferred onto the wooden surface. It adds a personal touch to your cooking space and makes for a thoughtful gift for food enthusiasts.

5. Custom Wooden Wall Art

If you’re looking to create a statement piece for your walls, personalized wooden wall art is an excellent choice. You can choose to transfer a favorite photograph, an inspirational quote, or a memorable date onto a wooden panel. The natural grain and texture of the wood will give your wall art a unique and rustic appearance.

6. Personalized Wooden Keychains

Add a touch of personalization to your keys with custom wooden keychains. You can have initials, names, or small designs transferred onto wooden keychain blanks. These make for great gifts or party favors, and they add a stylish and unique touch to your everyday essentials.

7. Custom Wooden Phone Cases

Your phone case can be more than just a protective accessory. With wood sublimation, you can personalize your phone case with a custom design or a favorite photograph. This adds a natural and rustic touch to your device while showcasing your unique style and personality.

8. Personalized Wooden Jewelry

Add a touch of nature to your accessories with personalized wooden jewelry. You can have names, initials, or even small images transferred onto wooden pendants, earrings, or bracelets. This creates a one-of-a-kind piece that reflects your individuality and love for nature.

In summary, personalized wood sublimation products offer endless possibilities for creative and unique decor items and gifts. Whether it’s a photo frame, a cutting board, or a keychain, the natural beauty of wood combined with personalized designs will surely impress and delight.

FAQs

Can I sublimate on wood?

Yes, you can sublimate on wood. Sublimation is a process where a design is printed on a special sublimation paper using sublimation ink, and then heat transferred onto a surface. To sublimate on wood, the wood needs to be coated with a special sublimation coating or treated with a polymer spray that allows the ink to bond with the surface.

Conclusion

In conclusion, sublimation printing on wood is a versatile and innovative technique that offers endless possibilities for personalized and unique creations. With its ability to transfer vibrant colors and intricate designs onto wood surfaces, sublimation opens up new horizons for home decor, personalized gifts, and artistic projects. The process is easy to learn and yields professional-looking results, making it suitable for both business and personal use. Whether you are looking to add a personal touch to your home or create customized products for your customers, sublimation on wood is a great option. Start exploring the world of sublimation on wood and unlock your creativity today!

By combining the natural beauty of wood with the vibrant colors of sublimation, you can create stunning and eye-catching pieces that stand out from the crowd. The durability of sublimation prints ensures that your creations will last for years to come, making them a valuable addition to any space. From photo frames and wall art to coasters and jewelry, sublimating on wood allows you to bring your ideas to life and make a lasting impression. Embrace the possibilities of sublimation on wood and let your creativity shine!